Zumalt V8 kits Design elements. Consolidated

Chapter 1

]These 1st few paragraphs are going to hard to write because I'm going to be discussing a subject that I know a lot about and I want it to be told in a way that is both fair and accurate. So please bear with me while I try to get thru these first few paragraphs. As you hear the story, you will realize why these first few paragraphs are so hard to get right.

This is a difficult post for me to get worded right. I want to offer you guys some facts here and tell you a true story that you would never believe if someone else told it to you. I want to tell it in a way that you don't think that I'm trying to be self serving. I've been working on Fieros for 16+ years now and I hate to say this but V-8 Fieros ARE my life, I really have no other serious interests. When you have spend the kind of time on this one subject as I have in the last 16 years you meet a lot of people, hear a lot of stories, and gather a lot of information that many others would consider worthless. Today I am about to start sharing with you more information about V-8 Fieros than you may ever have imagined existed.

Currently there is another thread on this Forum that asks about the HTD V-8 Engine conversion kits. https://www.fiero.nl/forum/Forum2/HTML/019020.html I was participating in that thread and the questions of why certain things were done the way they were in the various V-8 kits came up. We talked about design & engineering developement and reasons why certain V-8 engine conversion kits shift the engine to the left in the car and and other technical questions.

At one point during that conversation I submitted that I could explain the apparent lack of common sense in the engineering of certain V-8 kits and others' in that thread expressed an interest in hearing just how a V-8 kit can be developed that had engineering problems.

That other thread has several people sitting on the edge of their seats ready to fling arrows at each other and I truely want this discussion to be about sharing some interesting information rather than become a flame war.

It will take several days and hours of typing for me to tell you this whole story. I swear that if this turns into a flame war, I will just keep all this to myself as I have kept it to myself for many years already.

Ok, now that you have gone and read the other thread, you should know the subject matter that was being discussed there.

Let's see if we can get this off to a smooth start.

From time to time, here on PFF and in other forums, the topic of the Zumalt V-8 engine conversion kits comes up. As part of those kinds of threads it always turns into a discussion copmparing my V-8 conversion kit to what has been known as the Zumwalt kit. Yes, I know, I'm mis-spelling the name Zumalt. I started doing that a long time ago and I did it on purpose. Wether is be Zumalt or Zumwalt we are all talking about the same thing. Many times in this thread I'll also call it the Z kit. You'll also notice that in this post and many others, I've always refered to the Zumwalt kit as "what has been known as the Zumwalt kit". When I have finished typing tonight you may want to consider re-naming that kit.

NOW... at this point it needs to be understood Right up front everyone needs to know that the HDT kit, the Fiero Plus kit, the Shelby kit the old Corson kit and a few others are direct and exact copies of what is known as the Zumalt kit. You don't have to take my word for it I can prove that to you later. In fact it also should be understood that I can prove everything I'm going to be telling you here.

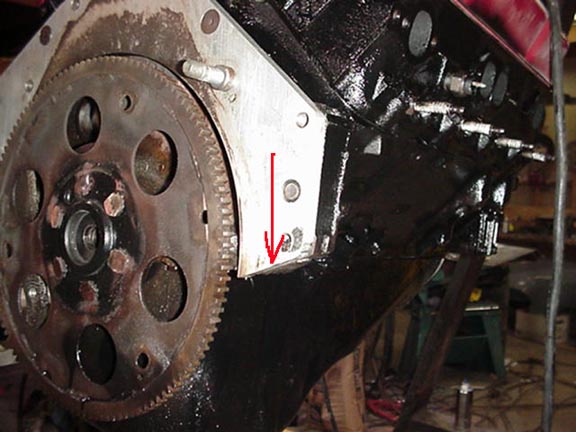

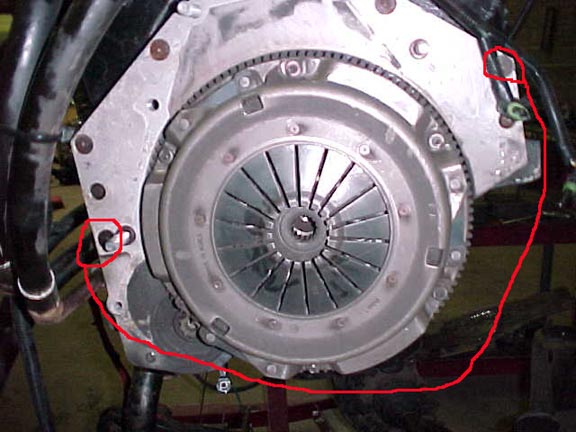

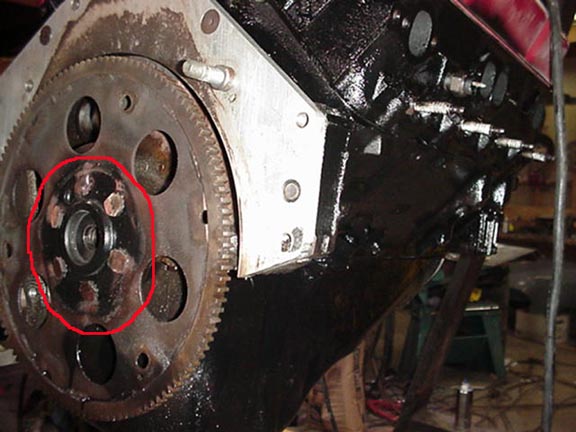

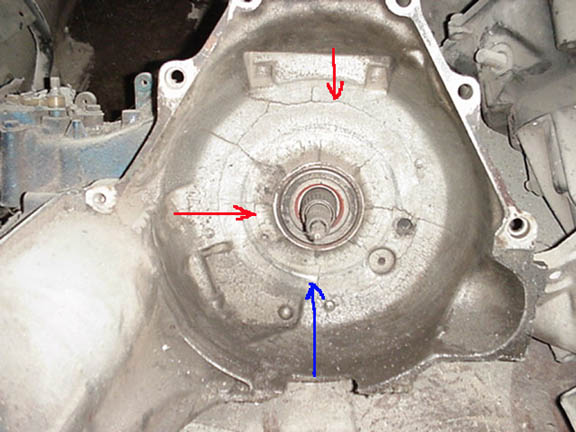

In page 2 of the other thread I refer to above the question of the design of the Flywheel and clutch and the reason for the 2" move of the engine came up and I responded with a few statements that led to the developement of this thread.

If you haven't read that thread yet you should go read it now. Don't bother to read the flames in that thread, just read the facts and opinions that are expressed there.

I'm sitting here waiting for you to finish reading that right now. da da da da da de de de de....... ok Welcome Back.

The 1st part of this story I had heard 2nd hand about 12 years ago. I wrote it off because there was no easy way to confirm it. Then back on 7-14-97 I had the story confirmed in writing by 2 of the three people who were actually there.

So here we go....

To understand the elements of design that led to the moving the negine over in the engine compartment and that cause the clutch/flywheel problems touched on in the other thread it is necessary that I tell you the whole story about the last 15 years or so of the kit known as the Zumwalt kit.

To understand the design elements you need to how this kit came into being, you need to know the History.

About 15 years ago 3 people got together to put together a V-8 Fiero. They all lived in the Kansas City Area. Doug Jones was the guy who financed the project and made some payments on the donor car when Gary got behind. Gary Zumalt who owned (or was making payments on) a Red 1985 Fiero GT automatic car. & J.D.Michael who owned a company called Econo Race Cars and had a 30,000 sf work area, J.D. was the designer/builder.

You'll recall that earlier in this post I said that I had heard a story about the Z kit many years ago and couldn't confirm it. You'll also remember that I finally got confirmation in 1997. That mail came from Doug Jones and at that time he gave me permission to use his EMail when I saw fit.

To tell this story about the initial design of the Z kit accurately, I'm going to post one of his EMails in it's entirety. I'll let him tell this part of the story.....

Subject:

Gary Zumult

Date:

Tue, 15 Jul 1997 16:53:17 -0500

From:

Doug <doug@awiz.com>

To:

v8archie@v8archie.com

CC:

cd156@usa.net

Archie,

I just got a CC of and an Email Clif Daniel sent to you and your reply. My name is Doug Jones and I am the one who financed Zumult when he needed the money the most --- the bank was getting ready to repo the V8 fiero. I did'nt know Gary very well however JD and me are good freinds. I made the payments on the Fiero and also provided $500 here and a $1000 there when needed. I hauled the Fiero on my trailer to car show. For my efforts I was to get a "piece of the action". No, I never received a thing for my efforts. I own Independence Electronics Inc http:\\www.awiz.com and I am the one who re-calabrated the tach to work with 8cyls instead of 6. Yep, a lot people got screwed over that V8 Fiero kit. In particular the man that developed it...J. D. Michael. JD owns ECONO RACE CARS and had a 30000 sq ft building in the limestone mines here in Independence Mo. He furnished the space, tools, and the engineering expertise to make the V8 Fiero a reality. $3000 won't make or break me, but JD put uncounted hours and

resources into that kit with the promise of fortunes to be made and got NOTHING in return. He could have been making money instead.

What happened?? In 1986 or 1987 JD was diagnosed with TB that he apparently caught in the 60's while serving in the Air Force in Vietnam. While JD was at the VA hospital getting treatment, Gary decided to go down to the shop and abscound with all the prints, drawings, patterns and the car. JD was too sick to do much about it. There were no written contracts that I know of. Everything was done on a handshake. Pretty shity thing to do to a friend, huh? Gary must have forgot about the Hot Rod Magazine article due

out in October 1987! I'll explain that later.

JD is a well known and talented dragster chassis builder. Him and I have

been freinds for years. Among many other things, JD made a pretty impressive tubular dragster chassis kit. He sold a few but lacked the financing to market it properly. The V8 Fiero kit was to be the golden

goose-free advertising in Hot Rod Magazine etc. -- but Gary ate the goose

rather then wait for the golden egg.

You may remember the Hot Rod Magazine article from October of 1987 promoting JD and Gary's V8 Fiero kit. Oh boy, the power of a national magazine!!! JD's phone number and address was in the article - Gary's was

not. JD got STACKS and STACKS of mail from people begging to buy the kit!! The phone rang off the wall and, considering the circumstances, were a source of aggravation to JD. People even sent money to pay for mailing a catalogue. And we did'nt have a kit to sell them! Wish we had known of you

at the time! The phone number is no longer any good but he still occasionaly gets an inquiry by mail. Of course Gary never got ONE of those leads! (JD also got some hot calls from customers looking for Gary.)

When one has stacks of inquiries in-hand it's pretty easy to get the money to fill the orders. A freind of mine, Roger Porter, saw the stacks of mail and offered to totally finance the project. We decided to buy a wrecked Fiero so we could get started re-creating the patterns. Unfortunatly JD's

TB and the medicine he was taking was beginning to take the wind out of his

sails. We decided it would be too much for him to take on the V8 fiero project at that time. We never pursued it again. A few years later JD moved the race car business from the large limestone mines to a workshop he built

at his home in Raytown Mo.

I just called JD and read him this Email to confirm my recollection of the V8 Fiero fiasco. He approves of this Email. At this time he has no interest whatsoever in even talking about the V8 Fiero.

I thought you would like to get the real story from the principles involved. This comes from the "horses mouth". I guess you know which end of the horse Gary's version would come from.

Doug Jones

Doug Jones, President

Independence Electronics Inc

119 S Main

Independence, Mo. 64050 USA

Phone: 816-836-1094

Fax: 816-252-7309

Internet: http://www.awiz.com

Tomorrow, we'll talk about how that initial design of an Automatic only kit evolved into a stick shift kit that has as many engineering issues as we've seen discussed many times.

Archie