(quickly, read the

Subject aloud 3 times

)

Eye-saving summary:

At the very end I ask if the fitting designed for the bubble flaring may also hold the Double flared tube tightly in place and properly sealed.

UPDATE a few hours later: You can also read my next posting here before reading the "full version". I found a website with illustrations.

Car:Fiero 86, 5sp Isoozoo, Tech4 inline rubber bands (aka iDuke), Flintstone Heavy Duty Brakes with new Reebok "pads"

------

Full version:

The saga continues as I prepare to work on the car again tomorrow. I want to make sure that we are not confusing bubble and Double, please excuse the heavy markup. I need to properly flare the end of the steel line on the rear brake behind the driver (see topic Brake hose>steel line frozen. Indications were that a Double flare could be used so...

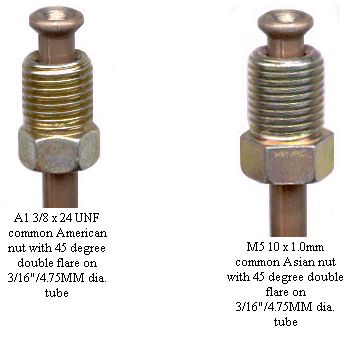

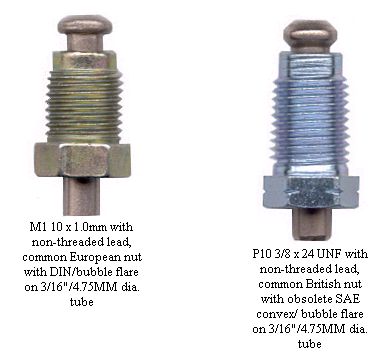

Thanks to John Stryker's advice, I went to get some scrap steel tubing to practice making good Double flares with my new kit. A parts store had 20" lengths of 3/16" steel lines with the fittings (or end nuts) installed.  BOTH types of flaring were available. I discovered that the fittings in these 2 steel lines are actually different -- not just their respective flare types .

BOTH types of flaring were available. I discovered that the fittings in these 2 steel lines are actually different -- not just their respective flare types .

I matched them at the store into the new brake hose that I have. The bubble flared line fit perfectly. Not so the one with Double flaring. Here, the fittings do screw smoothly into the hose end, but the steel line stays loose. Obviously, no good. WTF, why are so many telling me to use Double flaring?

So, to do this right I HAD TO bubble flare the line in the car at the point where I'll cut the old damaged end? It seemed like I had no choice but to get the expensive $100 bubble flaring kit. Another problem: the nearest such kit left at a store in South Florida is about 50 miles away and the blasted traffic is heavy. Plus these kits are non-stock items, their computer says it is there but they weren't able to confirm it physically.

Another problem: the nearest such kit left at a store in South Florida is about 50 miles away and the blasted traffic is heavy. Plus these kits are non-stock items, their computer says it is there but they weren't able to confirm it physically.

At that point, a thought came to mind. If these things are SO hard to get and expensive, what are the Fiero crowd and other GM owners doing? I gather that many:

-- save the old bubble type fittings (or manage to acquire them new, hard as it is)

-- but then they use them with Double flaring (instead of the original bubble flaring) ...

...because, darn, it LOOKS like this could work!  This would explain why so many people suggest a Double flare be used.

This would explain why so many people suggest a Double flare be used.

In other words, the fitting designed for the bubble flaring may also hold the Double flared tube tightly in place and properly sealed. Is this the case? Is it safe?

TIA for the help,

Beno

[This message has been edited by Jdlog (edited 04-01-2005).]

)

) BOTH types of flaring were available. I discovered that the fittings in these 2 steel lines are actually different -- not just their respective flare types .

BOTH types of flaring were available. I discovered that the fittings in these 2 steel lines are actually different -- not just their respective flare types .  This would explain why so many people suggest a Double flare be used.

This would explain why so many people suggest a Double flare be used.

.

.