the following is thanks to

http://captfiero.com/turbo.htmWell if you are looking for turbo's and turbo info you have came to the right place. I am not selling anything, so if you think I am going to be giving you a turbo for your Fiero eeh don't count on it. LOL What I am going to try and show is really how easy or hard it is to turbo charge a V6 Fiero. I am going to try and show you a list of parts that just could save your motor in the long run. Everything that I am going work with will err on the side of caution. I will always try to run a little on the rich side, (rich = more gas than air) I will keep the boost levels under 10psi Especially with the stock Fiero compression ratio of between 8.5 and 8.9. Well enough chatter lets get right down to business

Parts who's got the parts. Well there are a ton of parts that you can and some that you will need to buy. Then there are some more that can be argued if you need it or not. Well getting right down to business

Fuel Injectors --Starting with the fuel system, injectors, it has been said that the stock 15# injectors when new can support 200hp with the right programming. The design one turbo kit has proven this. But if we flash to the real world here, none of us have brand new injectors in our cars. Some of them only perform as well as a new 10# injector. So we should be looking at some larger injectors. This can be a massive expense if you just run with credit card in hand down to the local tuner shop and say "Big Injectors Please" sure you could drop as much as 1000$ for a set of 6, but are we Bill Gates here. I don't think so. Well so where do we get our new injectors. FORD, yep FORD I hate to say it, but the 5.0 Mustang has created such a huge amount of buying power that you can get the Mustang injectors for Pennies on the $$ and they plug right into the Stock Fiero Fuel Rail. If you are lucky like I was, I managed to find a set of near New 19# injectors on ebay for a grand total of 28$, no I did not leave off a zero there. Some guy was upgrading his stock 19's because he had just bought the car new and was installing a supercharger so the 19's were useless to him. I believe if you were to buy this set brand new you could get it for about 300$. Well now you have injectors that will safely support up to 240hp on a 2.8 block.

Fuel Pressure -- Ok your stock regulator is set for aprx. 28lbs at idle and when your stand on it the fuel pressure rises to about 50psi. This is great and fine and dandy, but as you start to make boost, you no longer have an 50lbs of fuel pressure going to atmosphere you have 50lbs being pushed back by 10lbs. So you get 40lbs oops. That is not going to do, as you are making more power, but you fuel system is now flowing less fuel. That is the perfect recipe for lean out, and melted pistons as well as the possibility for detonation. The solution is a "Rising Rate Fuel Pressure Regulator" this is a neat little gadget that can either replace your stock regulator, or go depending on style that you buy can be hooked into your fuel return line going to your tank. As this gadget senses boost, it will block the flow of fuel to your tank from the fuel return line. When it does this, your fuel pressure will go up, this is a Very Good Thing. Now you think this is all fine and good, well it sorta is, but there is still room for the bigger injectors. So it is a good idea to keep those Ford Injectors in the back of your mind.

Pistons and Rings, hmm, well this is a debatable subject on what will and will not work.

Forged Pistons-- Obviously the best pistons are Forged Pistons, but they are also the most expensive, around 400$ for a set of 6.

Hyperutectic's-- Next in line is a set of good Hyperutectic's the only problem with hypereutectic pistons is they will crack under heavy detonation, but the plus side is that they will not burn or melt nearly as easy as a cast piston. Burning holes in pistons is a problem caused when your fuel system gets too lean, (not enough gas).

Cast Pistons-- Cast Pistons are by far the cheapest out there, and will work with a turbo motor. Many a person has done a low boost 7-10lbs of boost on cast pistons. You just have to be more careful with them and not run high boost as well as make very sure that you don't run lean.

Piston Rings-- This can get very argumentative. I personally have heard really good things and really bad things about the new Gap-less rings when used in turbo applications, so I can not recommend them or tell you to stay away from them. The rings I do know about are the Chrom-Moly rings and the Cast Rings.

Chrome-Molly are very hard, and when seated in your cylinder walls should not wear out EVER. In most cases you will end up wearing your motor out before you wear out the rings. These should give you a good safe guard against cracking a ring when running boost or even Nitrous. (more to come on that later)

Cast Rings again it is kinda the same boat as the cast pistons, they can be used, they will work, but if your motor has more than 100,000 miles on it, it is a good bet that your stock cast rings are wearing a bit thin and you might want to consider replacing them before you toss all your money into a turbo kit. If you don't you might end up with a 3000$ Fiero a 1000$ turbo and a 10$ blown motor that smokes like Mt. St. Helens.

Rockers-- Well the rockers are the things on top of the heads that change the cam shaft lobe motion into the valve motion. So for every time the piston moves up and down each rocker has to open and close a valve for that cylinder. The stamped steel stock rockers are all well and good, but if you plan to run your motor hard a set of 1.52 roller or roller tip rockers will save you a ton of grief in the long run. The roller tip rockers reduce the lateral friction on the valve guides this reduces wear and will keep your motor smoke free for a much longer time than the stock steel rockers. This is especially true with high revving turbo motor's.

Ignition System Oooh Spark's. HeHe.

Well your stock ignition if it is in like new shape will work, but it is recommended against it. There are several manufacturers of good aftermarket ignition systems, but I am a fan of the tried and true MSD series. I personally use the MSD 6A ignition box that hooks right to your Battery, it is triggered by your stock wiring to fire an MSD Blaster II coil that sends the juice out to your cap and rotor and on to your spark plug wires, Via MSD Superconductor Wires, out to Plain DELCO STEEL CORE PLUGS. This is what MSD recommends is the steel core plugs the regular ones you buy not some fancy platinum or other funny plug. I am considering giving the AC Delco Rapid Fire Plugs a shot though.

Intake and Exhaust. Now comes some more arguable stuff. When you "boost a motor" you are no longer trying to just let the air flow in and flow out. Your are cramming it down its little throat, and when it is burnt your are shoving it out like wild fire. Headers and bigger intake manifolds and porting is still of value but not nearly as important now.

Engine Electronics

ECM the good news is the stock ECM will work. Any and all Fiero ECM's will work. If you choose to go with the Stock ECM your best bet is to find an 85ECM as it is modifiable to work exceptionally well with a turbo. The only confirmed details I have are the fuel mapping on the 85 V6 is different (better) and the prom chip and be changed to work with a knock sensor)

Map Sensor. The stock MAP (Manifold Absolute Pressure) only reads 1 atmosphere negative that means it can read 14.7 pounds of vacuum but it can not read boost. A 2-Bar map can read + or - 14.7 pounds of Vacuum up to 14.7 pounds of boost. Unless you are building a full blow race motor and are shooting for over 15lbs of boost you will only need to buy a 2 bar not a 3 bar.

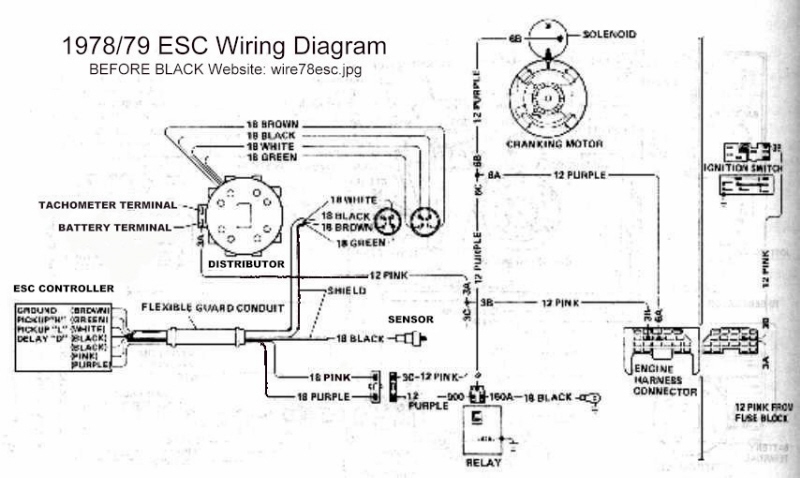

Ignition Timing Controls. MSD makes a neat unit that plugs into a vacuum source on your motor and can pick on boost conditions and retard your timing as boost increases. This is a really good thing as detonation is the leading cause of engine failure in almost any performance application. You can also get knock sensors these neat little guys screw into your engine block (the 2.8 already has the mounting boss for it) and listen to your motor, yes it can hear what is going on in your motor. When they hear detonation it starts retarding your timing. The nice thing about knock sensors is that you set your timing up at the most advance you would ever want to run. Then when you put say 100 oct.. race gas in your car it will allow the timing to be advanced on its own, but when you put say the cheap gas in your car it will retard the timing so it can save your motor.

The Boost Gauge, yes you will NEED a boost gauge, this will mounted in your car someplace within easy view. This will monitor how much pressure is in your intake when you first get this in your car, it will be hard to keep your eyes off of it. As you will be so proud to see your engine making boost. Aside from the huge grin on your face as you are sucked into your seat as the gauge reads higher and higher boost levels.

Air Fuel Meter, ah the never ending challenge to keep your motor from leaning out. This little doo-hicky plugs into your O2 sensor or can be hooked to a second O2 sensor that can be welded into your down-pipe. Generally they have a series of LED's (light emitting diode's) in 3 colours Red for too lean, yellow for getting a little lean, green for just right, and last one for too much fuel. Priced at around 100$ they are nice to have but are not needed. However I like lots of bells and whistles especially ones that show me what my motor is doing.

The Turbo---, Ok now for the biggie, you have all the stuff that you think you will need to have for this beast, it is time to start looking for a suitable turbo. Now this is where I get stuck myself, not being a turbo freak until about 6 months ago this is what I have learned so far. The turbo's on the dodge Daytona 2.2 and the turbo's on the Ford Thunderbird's are T3 turbo's and they are almost perfect for our applications. They are small enough that they will spool up at a relatively low rpm and begin creating boost at or near 2000rpms. The draw back is that they will run out of oomph at around 6000-6500 rpms. Don't worry if you are using a stock motor and stock fuel system this will be more than enough for a 2.8. If you have a modified motor you can still run this very well, and should be happy with it. The kicker to this is that there is a common swap with the T3 and that they take the compressor housing and exhaust housing apart, the compressor side is machined a bit and a larger compressor is installed, this allows the turbo to push a lot more air when the exhaust side is spinning at the same speed. This is called a (you guessed it) T3/T4 hybrid. A T3/T4 can be used to make up to 400hp, Just don't think your stock motor will do it. There are literally hundreds of variations of turbo's on the market today, ranging from Water Cooled, Oil Cooled, Oil and Water cooled. Ceramic bearing turbo's, ball bearing turbo's and the list can go on and on. I am looking into the Oil Cooled style myself. I understand that the water cooled is better but for cost purposes it will be an oil cooled unit. Prices can range anywhere from 20$ for a boneyard turbo up to as much as your wallet will allow. I have seen them for over 2000$ for a single turbo unit. You can count on spending around 100$ for a good used one or about 500$ for a new entry level model. Don't take this as the "die hard numbers" as I am new to this turbo thing myself. One thing that is nice about using a T3 turbo is there are lots of them out there, so the price is usually decent and you can find upgrade parts for less than some of the more exotic kits out there.

Getting Oil or water to the Turbo, as I know nothing about water cooled turbo's I am going to be talking about oil cooled turbo's. This was one thing that scared the heck out of me at first when looking into the designs of turbo's and Ya know what, it shouldn't. Why because as always the most confusing questions generally have the simplest answers. I have some pics of this that I will post someplace on this site. 1st you need to get your oil from someplace. That someplace is your oil pressure sending unit location, you use a T-fitting that runs splits off, one side goes to your turbo and the other side goes to your Oil Pressure sending unit. Ok that makes that easy, till you realize that all the oil is going into your turbo and on to your floor. Oops, quick hurry get the bucket. No No I am just kidding. The oil return line coming out of your turbo goes into your oil pan. You must punch a small hole in your oil pan and have a "bung" (bolt) welded onto your pan, that so that the oil coming out of your turbo goes back into the pan. The alternate source for oil is with a remote mount oil filter and you would get your pressure feed for the turbo from the oil filters exit side. This would give you cleaner oil and slightly cooler oil as it is no longer bolted to the block and has a chance to cool slightly in the filter. Especially if you use a filter cooler (filter cooler, is a large heat sink with fins that wrap around your stock filter and held in place with a large hose clamp) They do not do a whole lot, but it has been proven that they do reduce oil temps slightly.

Air Pressure its got to get into your motor somehow. Well most people use either stainless or aluminum tubing to duct the air from the turbo into the motor, this is a relatively straight forward thing. I am not to familiar with how the bends are set up or if you can get rubber or poly elbows to correct the problem of tight spaces.

Intercooler-- An intercooler will always help a turbo motor, but the question is do we need one considering we will be running under 10psi. For whatever reason 10psi seems to be the magic number for an intercooler to be used. I am sorta looking into using one on my car, but with the already awesome cold air intake that we have and the relatively low boost I plan to run it should not be a problem. I have seen intercoolers that were the size of a shoe box, and had the inlet and outlets in almost the perfect locations for us to use on our cars.

Exhaust Y-Pipe-- Ok here is some more things that are odd, well, from what I understand having the turbo as close to the exhaust manifolds as possible is your best bet, but with the Fiero 4 and 5spd cars, that is not always possible as the shifter linkage seems to plop right down between the 2. I have seen a couple of different ways to mount it, the best being near the cruise control location. It does make for the distance of the rear manifold to be much longer than the distance of the front manifold, but I think that will be alright. I have seen the easiest way to do this seems to be to go to your local "BIG CHAIN" auto parts stores and buy some raw exhaust tubing in different sizes and bends then go back to your car and play tetras for a little bit until you get an idea of what design your new Y-Pipe is going to take, then you take you designee to the local exhaust shop and explain what you want and how you want it routed and weld it all up and probably even show you a thing or 2 that you may not see. Like the way your EGR should be mounted and such. There are several different designs of y-pipes ranging from ones that will bolt a turbo right into your stock exhaust system right up to ultra high end ones that require a totally new exhaust system.

[This message has been edited by 3.6lvvt6spdgt (edited 10-26-2007).]