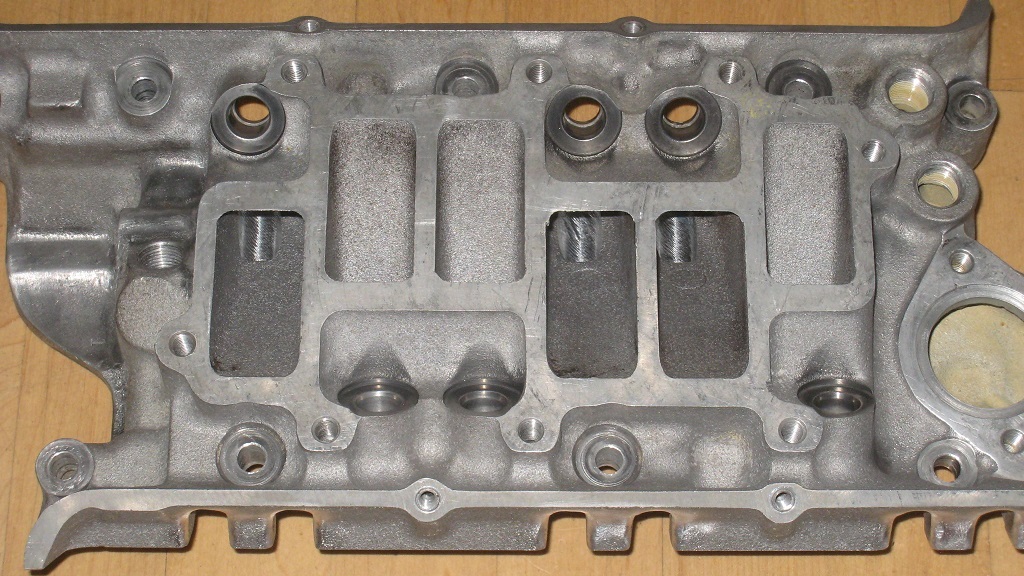

An update, since this project is still alive. The intake manifold is now back from the machine shop.

The six outlets have been drilled and tapped to 1/8 NPT:

There is also clearance for a thin-wall 7/16" hex socket; needed for screwing in the nozzles:

So far, I've done a two week long soak test of items known to be e-nickel plated, and they've held up to windshield washer fluid. Furthermore, my online searches have found that the water/meth distributors use nickel plating on the fittings they sell for water/meth use. So, e-nickel it is!

Since I didn't know where to begin with specifying e-nickel plating, I referred to the ASTM B733-15 standard on the subject.

Apparently, thicker = more corrosion resistance, so I asked for SC4 = 0.003" thickness. With this plating thickness, the straight threaded holes will no longer fit the bolts correctly, so I have requested that they be left unplated.

I want the NPT threads to be plated, especially those for water/alcohol connections. Anyway, with a tapered thread, all that's going to happen is that the fittings will just sit slightly higher above the surface.

I asked for high phosphorus, since that seems to be good for corrosion resistance (but I'm guessing). The plating shop I am in communication with can only do 5 - 9% phosphorus, but that's good enough I suppose?

Not that I have much choice, the other two shops I've contacted have ignored my RFQs...

I'll be bringing the intake next week to the shop that has communicated with me, for face-to-face discussions on how to proceed.

********************************************************************************

In ASTM B733-15, there is a mention of a post-plating baking for enhanced adhesion of the plating on aluminium.

The recommended bake temperature for age-hardening aluminium alloys is less than the suggested temperature for non-age-hardening aluminium alloys.

I interpret that to mean that the higher temperature baking makes the plating stick better, but it will over-age aluminium, if it's the kind that age-hardens.

If I have no information, I will err on the side of not damaging the aluminium, at the risk of an inferior plating adhesion.

So, if a Fiero historian does know that the intake is made of, I'd like to know too!