|

| Question about using Turbo's on a motor (Page 1/4) |

|

qwikgta

|

DEC 05, 06:44 PM

|

|

So I have an extra low mileage 3.1L motor that was going into my 87 GT but I sold the car and its just sitting on a stand. When walking my local Pick n Pull I noticed a couple Chevy Sonic's w/ the turbo 1.4L motors and got to thinking about using two of them, one on each bank, and building a twin turbo motor. I already have a line on some steel tube headers that have a center dump so I'm sure I could get them made up w/ the turbo bracket or V clamp so the mechanical side should be easy. My questions are more on the tuning side, how easy/difficult is it to tune twin turbos on any motor? I'm sure one larger turbo is better but I just want to ask about the twin's first. Thanks in advance for any help

Rob

|

|

|

Notorio

|

DEC 05, 07:42 PM

|

|

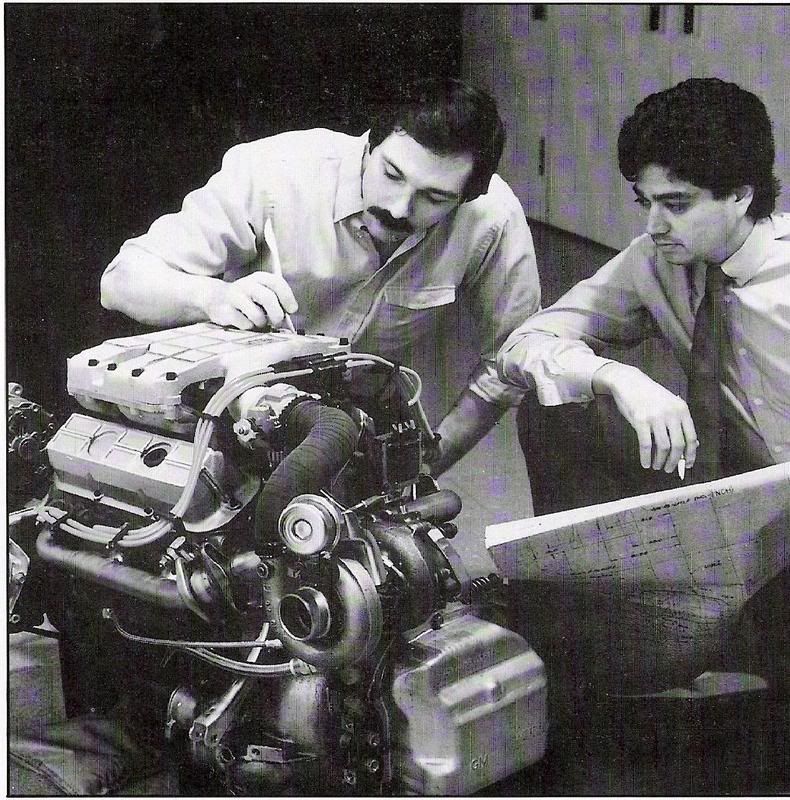

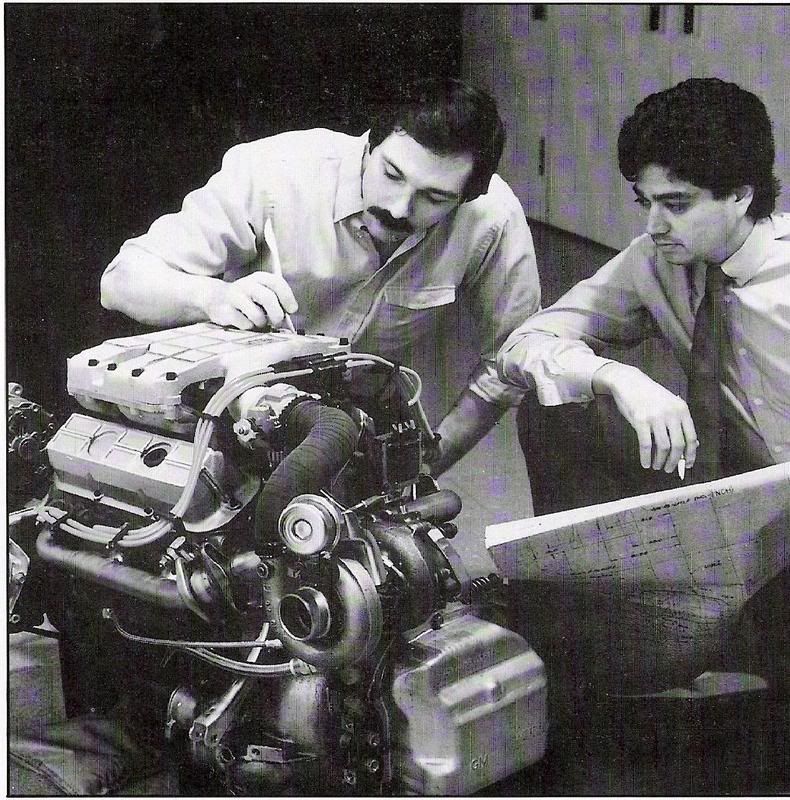

There are a lot of posts on this if you search for 'twin turbo' in entire forum + archives. Many negative opinions, most complaints about the difficulty of tuning. But here is a picture from GM on their twin turbo engine that sports a tantalizingly elegant set up ...

v6 2.8 twin turbo how hard to do? (from 2007)[This message has been edited by Notorio (edited 12-05-2021).]

|

|

|

qwikgta

|

DEC 05, 07:58 PM

|

|

|

Yep, did a search for twin turbo's and found what I was looking for. Thanks

|

|

|

cam-a-lot

|

DEC 05, 08:07 PM

|

|

Step one on the road to recovery.....stop using an apostrophe when describing dual nouns.

More than one turbo- Turbos. Not turbo's

More than one Fiero- Fieros . Not Fiero's

Best regards,

Spellng Nazi

|

|

|

pmbrunelle

|

DEC 05, 08:43 PM

|

|

If both compressors are in parallel, with both compressor discharges feeding into the same throttle body, it wouldn't add any complexity controls-wise. The only aspect that would be twinned would be the turbos and piping. The two small turbos could work together as one larger turbo.

On the other hand, if you had a dual-plenum intake, with two MAP sensors (and potentially different manifold pressures for each bank), and cross-connected turbos, that may be outside the realm of typical ECU hardware.

Also if you wanted to to sequential turbos, you might need more specialized ECU hardware to do it.

| quote | Originally posted by Notorio:

There are a lot of posts on this if you search for 'twin turbo' in entire forum + archives. Many negative opinions, most complaints about the difficulty of tuning. But here is a picture from GM on their twin turbo engine that sports a tantalizingly elegant set up ...

v6 2.8 twin turbo how hard to do? (from 2007)

|

|

That turbo is located smack in the middle of the Fiero transmission shift linkages... so you might need to get creative if you wanted to implement that.

Also note that a rear-pointing turbine exhaust is not ideal if you want to package a catalyst, a muffler, and a full trunk.[This message has been edited by pmbrunelle (edited 12-05-2021).]

|

|

|

qwikgta

|

DEC 06, 05:02 PM

|

|

| quote | Originally posted by cam-a-lot:

Step one on the road to recovery.....stop using an apostrophe when describing dual nouns.

More than one turbo- Turbos. Not turbo's

More than one Fiero- Fieros . Not Fiero's

Best regards,

Spellng Nazi

|

|

get a life

|

|

|

Dennis LaGrua

|

DEC 08, 04:06 PM

|

|

|

Installing a turbo can be a bolt on/plumbing job but there is more to it than that. For low boost 5-7 lbs you can achieve a successful install but if you go to higher boost levels you will need forged pistons and ideally a turbo camshaft. The tuning can be tricky on these as your ECM will need to be reprogrammed to operate with a 2 BAR MAP sensor with a timing table in the program for vacuum and boost. ------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

hyperv6

|

DEC 09, 07:47 AM

|

|

I would agree with Dennis here. Before you get too far I would speak to a tuner who has turbo experience and show him what you want to do.

It is easy to bolt the parts on but to get them to run correctly and live is another.

To get power you need decent boost but then in the 60 degree engine the head gaskets start to go, then the pistons and rods or even a crank.

Get the fuel mixture wrong you will burn a piston. On top of that you need to get the turbo oiling right or you lose a turbo.

Now you are up to the tuning where that has problems all its own.

I ran a 2.0Turbo for 10 years, I saw first hand what all GM did to make the engine survive and make power. They nearly re engineered the engine. They reduced the size to 2.0 from 2.5, they made a special head and block. They created special oil cooling for the pistons and more. My engine made 300 HP and 23 PSI of boost but it was not something I could have done on my own as this was a complete engineered and mfg package from GM.

Then you need to deal with under hood heat.

Based on those from the past I have seen you will lose the head gaskets first and then the pistons if you make any kind of boost.

Back in the old days they made a bolt on kit for a Trans Am 400 CID. Our customer bolted it on. It worked for a while then the crank broke. It had horrible lag as it was a large single unit.

Don't want to be negative here but I have seen too many here end up with a car they can't drive or hate to drive due to a turbo install project. Few get it right so just do your homework before you start.

|

|

|

pmbrunelle

|

DEC 09, 09:00 PM

|

|

Regarding re-engineering the engine, I don't really think that's necessary (or economically feasible in most cases) for a garage build.

OEMs need to be thorough in what they do, because even 1/100 engines blowing up is pretty catastrophic money-wise and reputation-wise. If you have that kind of reliability for a garage build, you'll probably be part of the lucky 99 without problems...

As for underhood heat, you plan the exhaust pipe routing accordingly and make heat shields in consequence.

Nowadays, there's a plethora of information available on the internet to the DIYer, which makes these turbocharging easier than it was even just 20 years ago. Tuning is easier now, with people modifying the tunes of ECUs, rather than using RRFPR and SAFC patches. Wideband oxygen sensors are affordable.

|

|

|

hyperv6

|

DEC 09, 09:46 PM

|

|

The main issue here is this engine was not made for high compression or higher pressures of turbocharging.

There was a guy in the 90’s from PA that did a lot with the 60 degree engine and learned a lot. He went through a number of engines to learn the failure points.

The durability even with low boost was not great. Head gaskets failures broken pistons were all seen at moderate boost levels.

My friends with a Shelby GLHS. He built a 11 second car but could never keep the engine to where it lived long.

By studying what the OE engines are doing it will teach you much of what they learned the hard way. The Buick GN is a classic today but the Buick Turbo T types prior to the GN with a water cooled housing all failed. That is why you never see them today. Same for the Monte Carlo Turbo. Most died by 30,000 miles.

Engines like the Chevy V 8 are forgiving as most were over built so mods make it easier to modify than other engines. 5 head bolts around a cylinder add strength as do some other features.

|

|

|

|