|

| check your jackstands. (Page 3/6) |

|

ltlfrari

|

APR 10, 09:21 AM

|

|

|

If the wheels are off I usually throw them under the car, with a 4x4 on top if there's room, for a little extra security. ------------------

Anything I might say is probably worth what you paid for it, so treat it accordingly!

Dave

www.ltlfrari.com

|

|

|

longjonsilver

|

APR 10, 12:31 PM

|

|

| quote | Originally posted by ltlfrari:

If the wheels are off I usually throw them under the car, with a 4x4 on top if there's room, for a little extra security.

|

|

That's exactly what i do too.

------------------

Astronomy says we will find a coded signal from outer space. Then we'll KNOW that life exists there, for coded signals aren't by chance.

Biology says there are coded genetic signals in every cell, but we KNOW that no intelligence created life.

I'm the original owner of a white ' 84 2M4 purchased Dec 10, 1983 from Pontiac. Always garaged, no rust, 4-wheel drifts are fun!

|

|

|

theogre

|

APR 10, 03:24 PM

|

|

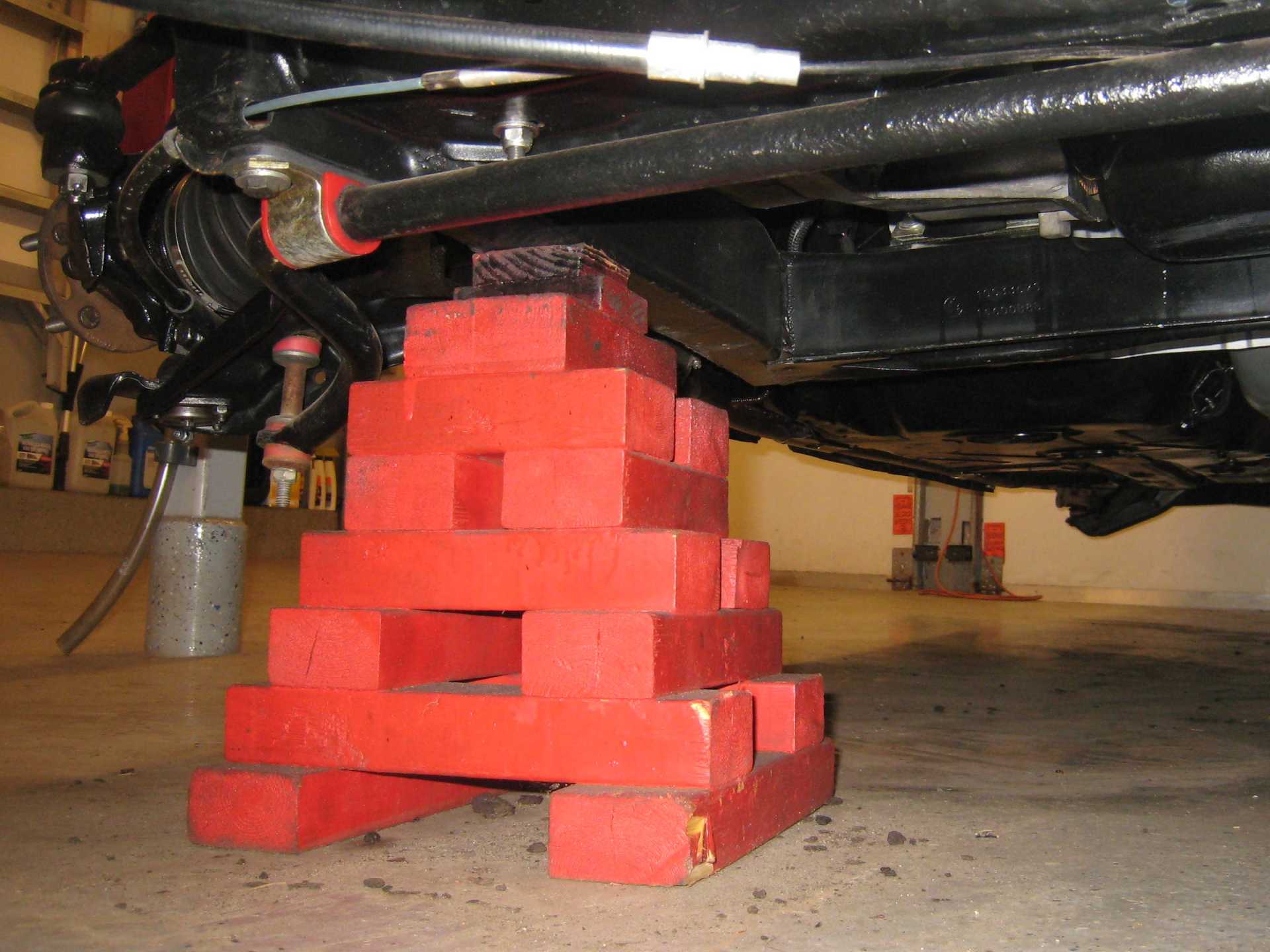

Wood Blocks above is just basic cribbing used for Thousands of Years and doesn't need screws glue etc to work for most jobs.

But even the best of any type of Cribbing, Jack stand, and so on can fail when load isn't centered etc.

Pyramid stacking, either above block stacking or shaped bottom most stand uses, helps but still have limits to keep crooked loads pushing sideways at the top.

| quote | Originally posted by ltlfrari:

If the wheels are off I usually throw them under the car, with a 4x4 on top if there's room, for a little extra security. |

|

⚠️ That has hurt or killed many people thinking rims are strong.

Steel rims can fail easier then most think when loaded in odd/nonstandard ways. Alloys rims can Break (or Burst w/ tire pressure) w/o Warning doing the same.

You see many junk yards w/ rims stacked under a car too.

Common is one on side on bottom w/ another stacked in it holding up whatever.

Regardless on the stacking method, Do Not think is safe and work under the vehicle.

IOW When a Vehicle is Sitting on rims or complete tires to work on is more likely the vehicle in sitting on Eggs w/o loading the whole Shell.

|

|

|

theogre

|

APR 10, 04:06 PM

|

|

Related Warning:

If you have or see cheap Tripod Jack Stands sim to This...

(From https://www.k-bid.com/auction/25426/item/23 by Google IMG search.)

Do Not use them! Not even on Concrete floors.

Even when new and have right pins not bolts shown here have big problems and most places no longer sells them.

Is very common to have the top saddle fold when load shifts to one side of the saddle and often drop the load w/o warning..

Used on dirt or asphalt can sink unevenly and drop the load w/o warning.

Many loose the OE pins and use Bolts... Most use wrong bolts and they break and drop the load w/o warning.

If you're thinking Cheap Chinese product... Wrong.

Many are made in the US and other places way before everything is made in China now.

Think Many where Recalled by CPSC etc decades ago but you still see many are still used or sold thru all of the second hand markets.

|

|

|

theogre

|

APR 10, 04:41 PM

|

|

|

|

Fiero Vice

|

APR 11, 12:25 AM

|

|

| quote | Originally posted by pmbrunelle:

Prime Minister Brunelle uses these home-made wood blocks:

Benefits (as I see them):

Easy to make: use 2x3 lumber, wood screws, glue (PL Premium or yellow glue), and red Tremclad (colour is up to you)

Not overly expensive either.

When supporting the pinch weld section below a car's rocker panel, the metal will bite a bit into the wood; low risk of slipping! Do orient the pinch weld perpendicular to the wood grain to avoid splitting.

When using these blocks on asphalt, the large surface area prevents sinking into the pavement.

They're quite strong enough; I have no qualms about getting under a car supported by these.

Edit: since these blocks were designed and built in Québec (a project between my dad and I), we dubbed them the Bloc Québécois.

|

|

I like this idea of yours.

I've always felt uncomfortable going under the car when I use jack stands.

I use the floor jack as backup, but sometime it gets in the way and don't trust it fully.

Now, with wood blocks as backup or even as primary, I would feel better, knowing I have a backup in case something goes wrong.

Instead of using screws, don't you think it would be better to use bolts to better secure the wood blocks, on top of glue?

From the look of the wood blocks, is it 3" horizontal and 2" vertical?

Thanks for sharing.

|

|

|

pmbrunelle

|

APR 11, 05:11 PM

|

|

| quote | Originally posted by Fiero Vice:

Instead of using screws, don't you think it would be better to use bolts to better secure the wood blocks, on top of glue?

|

|

Like ogre said, screws/glue are not technically necessary for the strength of the blocks. My blocks are glued/screwed together so that I don't have to putz around playing Jenga each time I want to lift my car; I just grab the assembled blocks and get to lifting. I think bolts would be overkill for nothing.

| quote | Originally posted by Fiero Vice:

From the look of the wood blocks, is it 3" horizontal and 2" vertical?

|

|

Yes, but it's not exactly 3" and 2".

The actual measurements of lumber are about 1/2" smaller for each dimension, so it's more like 2-1/2" x 1-1/2".

|

|

|

GTGeff

|

APR 11, 06:06 PM

|

|

I use jackstands and leave the jack in place while working under the car. I also chock the wheels to prevent rolling. If possible I have my son help to serve as a spotter.

Unfortunately, I lost a brother-in-law when he was 24-years old so a very expensive lesson learned. He dis-connected a transmission from the engine while under a car and the car rolled off the blocks crushing him.

|

|

|

theogre

|

APR 11, 07:34 PM

|

|

Side note:

Nearly All "lumber yard" wood (Dimensional Lumber) is "Under sized" by ~ ½ inch for the US market.

So you buy "2x3" to get 1.5x2.5, "2x4" gets 2.5x3.5 etc.

Rough cut wood was nearly close to real size say 2" x 4" but now less.

Was a time the under size was ~ ¼" but saw mills made changes to get more finish wood out of a tree plus get more money out of buyers.

Think rough cut now is ~ 1.75x3.75.

Rough cut wood is basically right from primary saw machine w/ all saw marks etc.

About the only thing I see now using rough cuts is companies making pallets and related use.

Part of the under size is cause by Planers to make finish/dimensional product. Planers cut ~ 1/16 to ⅛" per side depending on several things.

|

|

|

theogre

|

APR 12, 12:44 AM

|

|

| quote | Originally posted by GTGeff:

I use jackstands and leave the jack in place while working under the car. I also chock the wheels to prevent rolling. If possible I have my son help to serve as a spotter.

Unfortunately, I lost a brother-in-law when he was 24-years old so a very expensive lesson learned. He dis-connected a transmission from the engine while under a car and the car rolled off the blocks crushing him.  |

|

There's that... Others have used concrete block or clay bricks that simply broke w/o warning hurting or killing them. Had one killed that way in town where I lived years ago. Is more common then most think because MSM doesn't report these. Might make local news but only when someone dies...

|

|

|

|