|

| Working Shift Gate (Page 1/1) |

|

IMSA GT

|

JUL 21, 03:17 PM

|

|

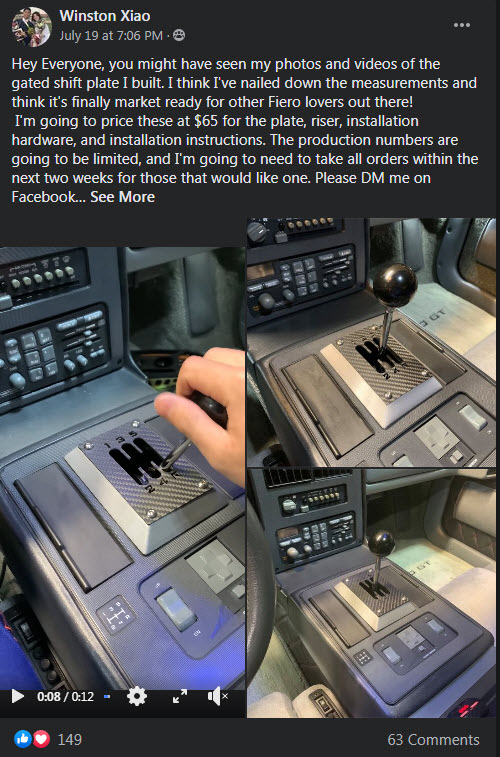

Found this on Facebook by accident as I don't frequent that place. It's a shame that people post items like this over there yet ignore a true Fiero forum like this one. Anyway, this looks like a very nice product. He has the pattern all figured out as well as the base which I assume helps align the shifter. Great if you want something different or if you have a replica.

|

|

|

Dsanchez214

|

JUL 21, 05:14 PM

|

|

Dam, I dont have FB.

I definitely want/need one.

Maybe some that has FB can send him our way and make them available here.

|

|

|

IMSA GT

|

JUL 21, 05:49 PM

|

|

| quote | Originally posted by Dsanchez214:

Dam, I dont have FB.

I definitely want/need one.

Maybe some that has FB can send him our way and make them available here.

|

|

Hopefully someone will send him over here. He made a very clean design and in his video, the shifts are dead-on in the gates.

|

|

|

Skybax

|

JUL 21, 07:26 PM

|

|

|

Nice, but the problem is that "dialed in" gate is only for his specific car, that's why nobody else did the true gated shifter in the last 3 decades, because there are so many different wear differences and the Fiero tolerances are wide.

|

|

|

Fiero Vice

|

JUL 21, 07:37 PM

|

|

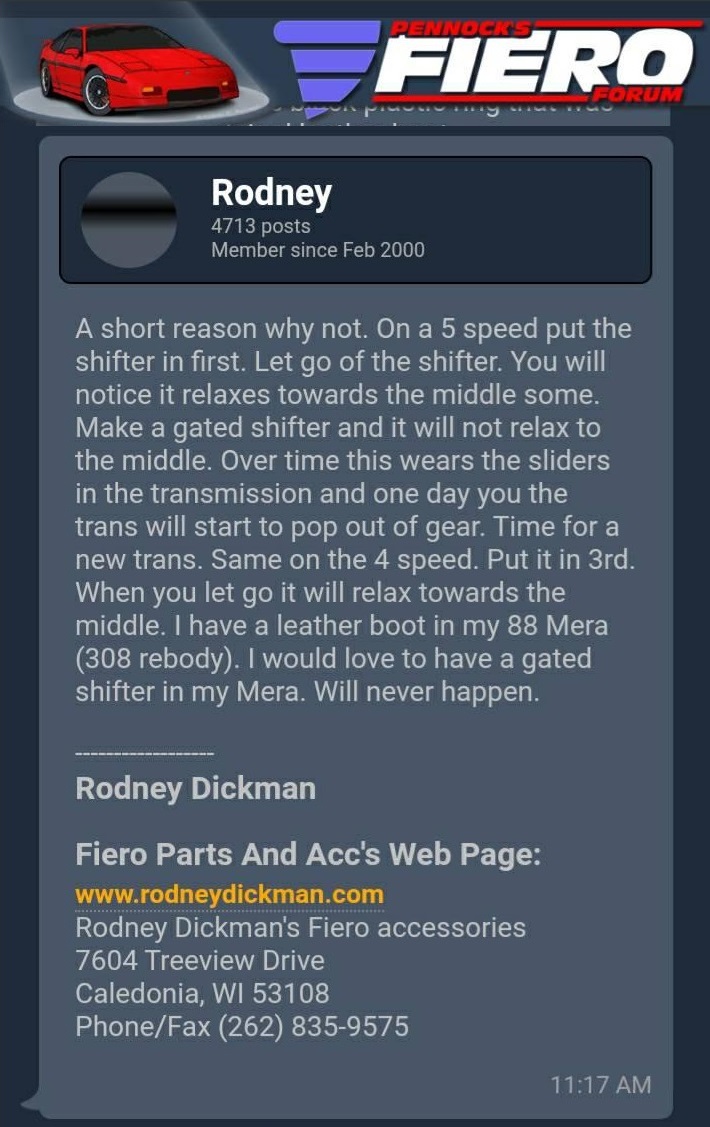

Yeah, while I think it's a cool idea & love the look of a gated shifter, please look at Rodney's advice on how a gated shifter will have an impact on Fiero's transmission.

I never want to shoot down anyone's idea or new product, but I wouldn't want anyone's transmission to get damaged either.

[This message has been edited by Fiero Vice (edited 07-21-2021).]

|

|

|

pmbrunelle

|

JUL 21, 08:39 PM

|

|

It's not that gated shifters are bad, it's that you have to throw away the stock X/Y mechanism, modify the transmission to use one cable per shift fork, and then use the gate to select the cable to be pushed back/forth.

A bunch of work to solve a non-problem...[This message has been edited by pmbrunelle (edited 07-21-2021).]

|

|

|

Australian

|

JUL 22, 05:50 AM

|

|

|

|

fieroguru

|

JUL 22, 07:14 PM

|

|

Let me start off by saying the F40 has a gated shifter built into the shift mechanism. There is a pin that rides in the gates in the center tube. This is one of the reasons for the notchy/clunky feel of shifting the F40.

A functional gated shifter plate has a few issues...

1. With new cables and rebuilt shifters there is still play in the side to side/front to back motion of the shifter shaft/knob. In the general raised area that this proposed gate is, the slop even with all new parts is still at least 1/8" or more. This means to avoid the shifter shaft from rubbing on the sides of the gates, there should be 1/8" of clearance on each side of the shifter shaft for the gates. Making the gates too wide, limits the material thickness separating the gates, which becomes a functional and aesthetic issue. Narrowing down the diameter of the shaft and raising the plate location helps balance things out, but there are practical limits.

2. Is when things wear, there will be more slop and the shifter shaft will start making contact with the sides of the gate (or the gate is designed for the shaft to rub the sides of the gate in the first place). The issue here is the contact will want to move the gate plate around as the shifter shaft bumps into it from all directions. The shift gate is attached to the chassis via the largest, most fragile, and difficult to replace piece of plastic in the Fiero (console skeleton) and the risk of breaking it is greatly increased with a functional gated shifter plate.

|

|

|

Australian

|

JUL 23, 05:49 AM

|

|

|

I will certainly agree it is more than likely the shifter will hit the sides that is why i have such large gap in my design. I did end up changing from a basic 6 speed gate design to 7 in order to have the amount of play. My shifter is a lot lower so also have issue with of the bulk of the knuckle sitting in way. The design requires a raised section because of it. [This message has been edited by Australian (edited 07-23-2021).]

|

|

|