|

| Fiero Leaf (Page 1/4) |

|

Wichita

|

MAY 21, 06:53 PM

|

|

I've been steadily working on going through the Fiero, mostly for rust prevention and full suspension restoration among other things.

Originally an Iron Duke and 5-speed, but I pulled the motor out and donated it. My plans are to convert to EV. I've had plans to prep and plan for the usual EV conversion motors, such as the AC-50, Warp 9 then really was going to pull the trigger for a Hyper9.

COVID made it sort of difficult to source a few things, but glad it did, because I got my hands on something even better. A Nissan Leaf EM-57 full stack (motor, gearbox, inverter, PDM - charger, dc/dc converter, bms). 147 HP and 200 ft/lb of torque.

Currently just doing some fine tune measurements to mount it on the cradle, doing some cv axle work, a lot of reading and watching those who do conversion projects, and trying to source a reasonable priced Leaf battery pack (they get snapped up fast for green energy home projects).

I originally planned to keep the 5-speed, because of the earlier motor choices would mate to it. With the Leaf gearbox, that has changed. I'll now sadly do a 5-speed delete and utilize the single gear box on the Leaf stack.

The full stack weighs about 200lbs less than the Duke and Izusu trans combo, so there is a bit of weight savings, but the batteries will subtract that weight savings.

But it's coming together. I'll use this thread to document the process.

[This message has been edited by Wichita (edited 05-21-2022).]

|

|

|

steve308

|

MAY 21, 07:45 PM

|

|

|

Good luck with the project! I hope you don't run into the problem with the batteries the early Leaf vehicles had which was / is early failure rate causing a lack of usable range.

|

|

|

Wichita

|

MAY 22, 01:56 PM

|

|

| quote | Originally posted by steve308:

Good luck with the project! I hope you don't run into the problem with the batteries the early Leaf vehicles had which was / is early failure rate causing a lack of usable range. |

|

That is the weird thing. Nissan didn't liquid cool their batteries, but they did liquid cool the motor and inverter, which is a very good thing.

I know they did a bit of redesign after the first two years (11-12) Gen-1 Leafs.

I haven't fully settled if I'll be using the Leaf battery pack or find some Tesla battery packs. Still tinkering with design, space and weight distribution for that on the Fiero.

|

|

|

Raydar

|

MAY 22, 02:52 PM

|

|

|

Pretty cool! Good luck with your build!

|

|

|

Australian

|

MAY 27, 04:20 AM

|

|

Fiero Radicchio

|

|

|

Newbfiero

|

MAY 27, 10:00 AM

|

|

|

|

Cheever3000

|

MAY 27, 03:19 PM

|

|

| quote | Originally posted by Australian:

Fiero Radicchio

|

|

That's appropriate, since it looks like it's on fire. Or is that exactly why it was called that?

|

|

|

robmox

|

MAY 31, 04:33 PM

|

|

|

I hope when you start working on this you do a build post. I'd love to follow along. If I slack too much on my LNF swap, I'd love to do an EV conversion.

|

|

|

2.5

|

JUN 02, 04:10 PM

|

|

This will be cool.

|

|

|

Wichita

|

JUN 02, 11:49 PM

|

|

I've actually done a cradle fit with the motor right now.

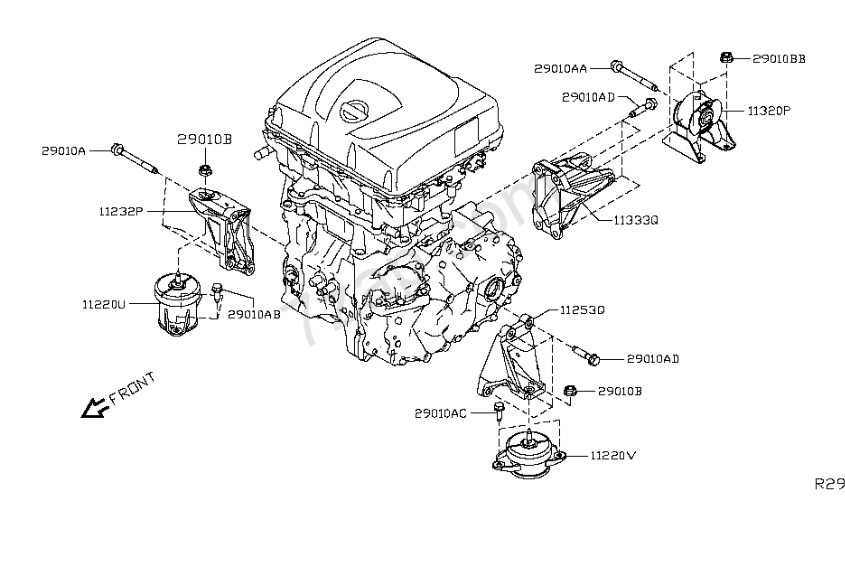

I'm using the existing Leaf motor mounts instead of modifying the existing Fiero ones. The Leaf has three, two up front on their side and one in the center rear. It's in a triangle shape.

I used the axle centerline of the Fiero as my prime meridian to start with the motor fit to the cradle. I have no idea how much time I spent measuring and remeasuring and checking and measuring, but using the Leaf motor assembly (has gear reducer attached... single speed transmission) axle centerline I was able to find the deadnuts on axle centerline from the Leaf to the Fiero.

Had a few things weirdly and coincidentally was a measurement match on the cradle. There is a tooling hole on the forward crossbeam on the passenger side of the cradle and from that tooling hole to one of the slotted forward transmission mount holes on the driver side was the exact dimensions from the Leaf's forward holes of the motor mount from left to right. This put the Leaf motor dead even in the middle of the cradle. The aft holes of the forward motor mounts line up to the cradle driver/passenger side cross members and it is in the forward slot of the a-arm, so there is no interference and nothing to do but drill a mounting hole in those locations.

I have a lot more to explain and more that I have done, but I should start uploading pictures of what I'm doing, before going on. But it is coming together very well. I have successfully already mounted the leaf motor on the cradle. I took it back off just to do a bit of painting and undercoating to it. I will reinstall it back up this weekend.[This message has been edited by Wichita (edited 06-02-2022).]

|

|

|

|