|

| My DIY rear Coil-over conversion (84 model)... play by play (Warning many pics) (Page 1/11) |

|

redraif

|

SEP 13, 01:54 PM

|

|

Well I searched alot to get all the information to do my do it yourself coil-over conversion to the rear of my 1984 Indy with KYB struts. Like many, my choice was two fold, both to lower the car & to be able to run a wider rear tire/wheel combo.

The first hurtle was to decide on the spring weight and length. I was debating b/w the 10 in and 12in as well as the 300Lb and 325Lb. Due to other members feedback and results in searching I learned to be able to run the wheel/tire option I wanted I needed to maximize my clearance. So I opted to go with a 10in spring to be sure the spring prech would remain as high as was possible and yet remain safe (coil bind and spring unseating while driving) Another member used wheels with a similar final offset placement in the wheel well and hit his perch with the tire when he used a 12inch spring. So 10in was the recommended fix for this. The spring weight... well that was a cost decision. I was able to get springs that were in stock and cheaper at my local summit by going with a summit 2.50 inside diameter spring in the 300LB. They were a nice black too! ($75 for the pair.) Figured I'm using the stock Duke and since its an INDY, I probably will not deviate much from this platform, motor wise, to worry about added weight in the rear to justify a heavier spring weight.

Next was the sleeve length and placement. I could go with a 5inch sleeve and keep a small part of the factory placed perch to seat the sleeve on, or I could remove the factory perch completely and let the sleeve rest on the bottom of the strut. After much deliberating I opted for the 7 inch sleeve resting on the bottom of the strut for strength and to cover more of the strut shaft for asthetics, as well as greater adjustability with my lowering pereferances. So I fought with Summit to try to get a sleeve from one of their vendors that I would NOT have to pay shipping on and was $10 cheaper then Coleman's, but for some reason they could not get the parts. So I went with Coleman Racing sleeves, the ID diameter was a clear 2.04 that would fit on my KYBs. Jegs was a bit cheaper on shipping , so I opted to buy from them. I thought about a 8inch sleeve for further asthetics, but time to get the part became a factor when Jegs said they had the 7in sleeve in stock, but the 8 in had a 6+ day wait. Ordered coleman part Number 420-701 (7in 2.04ID) FYI : Jegs part number is 193-420-701 ($101 shipped for the pair)

So I collected all the parts together and waited for time to begin.... I also noticed my factroy dust boots were missing, so up to the attic I went to locate them. My packrat side will never let something like this get tossed. Low and behold I found them!

Here they are with the rest of the parts

The sleeves came in Friday, but due to a dock and seawall renovation, things are slowed down. This renovation may interupt my process through this build, but I will be detailing my process through this as it might help someone down the line with their conversion. Many pics to come... this is how I learn... by seeing, so it might lend a hand.

Thank you to Fierohoho as my direction came from his DIY thread!

FYI: You will see some editing as I go along on this thread. I will be making corrections or clarifying things as I go for a better more informative thread

****UPDATE****

Darth Fiero did his own coil over mod and had this to add to my parts links on 08-04-2014 08:44 PM regarding what parts he used!

| quote | Originally posted by Darth Fiero:

....The Coleman sleeve and adjuster kits mentioned in the OP aren't $101 for the pair anymore (they are now $137.98 for the pair) and they aren't always in stock at Jeg's. Instead, I found some Allstar ALL64143 sleeve kits from Amazon.com for $38.99 each (77.98 for the pair) which will fit over the KYB struts if you modify the sleeves themselves a bit (there are some raised portions inside the sleeve that need to be sanded down a bit - this can be done with a dremel and sandpaper roll).

I bought the 10" tall 325lb Summit springs for my Fiero ($83.94 for the pair).

I also bought some Energy Suspension 9.6118R upper spring pads (install between the spring and the upper strut plate) for $10.81 for the pair from Amazon.com as well.

You'll need to remove the stock jounce bumper (bump stop limiter) from your stock Fiero strut boots if you want to reuse them since the Fiero strut boots won't fit inside the 2.5" ID coil-over springs. If you want strut boots, the only thing I've found that will fit are the Bilstein "Service-7" blue strut boots sold here: http://www.maximummotorspor...over-strut-P975.aspx, but I don't think the OE Fiero jounce bumpers will fit inside these strut boots (but you can get some aftermarket ones if you want them).

My Fiero has a 3800 Series 2 Turbocharged V6 and 4T60-E automatic trans. The 325 lb rate springs seem to be a very good match for it offering much improved handling without hardly any loss of ride quality over a stock Fiero GT spring. I will admit the stock Fiero GT rear springs I was using seemed overloaded with the increased weight of my powertrain, which was producing an instability issue during hard cornering and evasive maneuvers at highway speeds.

-ryan

|

|

[This message has been edited by redraif (edited 09-15-2014).]

|

|

|

redraif

|

SEP 13, 02:03 PM

|

|

Disclaimer: I learned as I went along during this build, using the guidance of those that have gone before and the knowledge I have from other cars. I am not a mechanic and have no formal training. Do all work on your own car at your own risk. Don't point at me if you screw up or get hurt... LOL!  Things may not go as simple as they were for me! I will note the good and the bad I come across it in my build. Things may not go as simple as they were for me! I will note the good and the bad I come across it in my build.

The parts on my car have been apart before and my car lives in the South, so take that into account if your car is bone stock or lives up North. PB Blaster is your friend for sticky bolts and nuts!

Lets get started...

Picture time... LOL!

Safety tip! Block the front wheels so the Fiero does not run away! A proper wheel chock is the way to go!

My car sits pretty low due to the small tires (takeoffs from my 87 Nissan Pulsar). So for extra clearance I use this little ramp my dad made years ago for the snapper mower. This gives me enough clearance to get under the car safely with the jack.

On a side note: Check out my dry rotted tire that refuses to hold air... UGH! This is the reason I used the wooden ramp on the other side. It did not help at all on this side with the tire so flat. The ramp on the other side gives me just enough body to ground clearance to get my low profile jack in on this side.

My poor car had been sitting so long the lugs were not wanting to budge without moving the whole car, so I blocked the back with a scrap of wood... It did the trick.

Breaking the lugs loose... yes I needed that huge breaker bar... LOL! You always want to do the intitial lug breaking loose while the car has it full weight on the ground. Once its up in the air the rim is too free to spin and breaking lugs loose can be a real PITA. If someone will get in and hold the brakes, but I'm not one to advise getting inside a car that is off the ground. But don't remove any of the lug nuts with car on the ground, you can damage the lug studs.

With the lugs broke loose, I slipped my jack in to lift the little one up! I used the cradle to lift the car. Just always make sure you are on square and aren't pinching anything like exhaust or brake cables. FYI: I don't trust jack points with real jacks. They don't have the recessed the factory jacks have. But I will not do any serious work under the car with a scissor jack! I ahve had these twist and collapse if the ground is not prefectly level. Instead, I always jack my cars up at the frame, front cross members, or rear chunk (front engine rwd cars). With really low cars that sometimes means using multiple jacks to get it done, but I have yet to mess a car up doing it this way.

Here we go

Wheel off... still needs some clean up too... ugh! And to think I cleaned this bad boy up once before. Guess I will be tackling it again as part of this build.

Shot of the stock coil spring... This thing is massive!

[This message has been edited by redraif (edited 09-15-2014).]

|

|

|

redraif

|

SEP 13, 02:13 PM

|

|

|

|

redraif

|

SEP 13, 02:27 PM

|

|

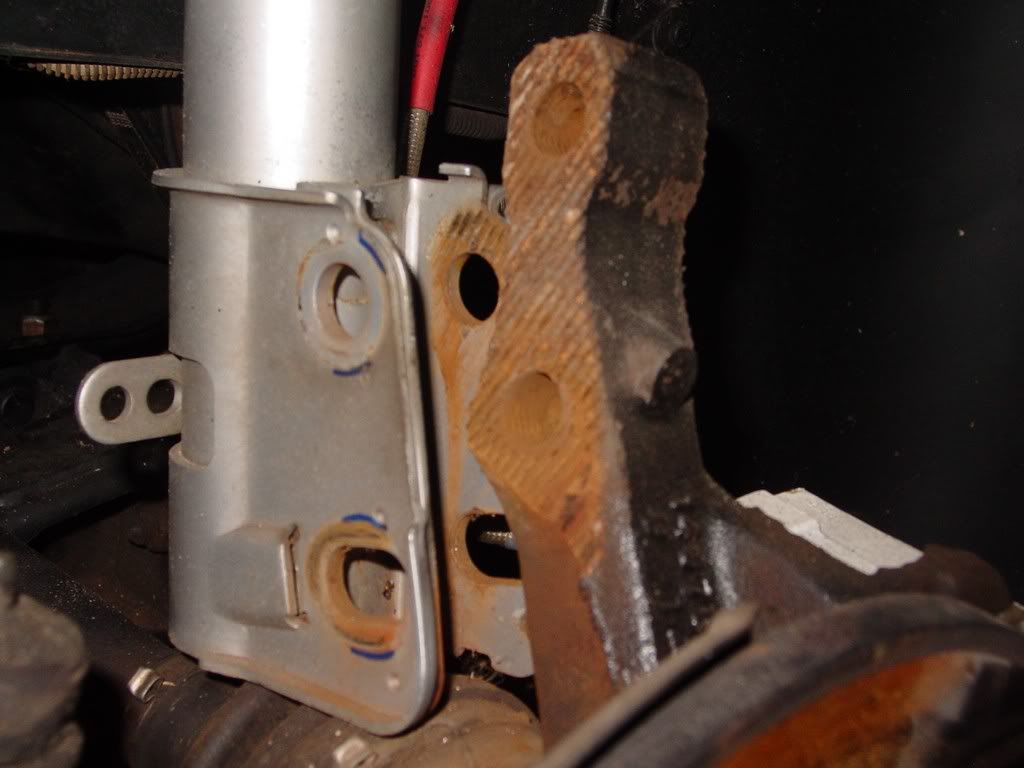

Now the massive bolts holding the strut to the spindle.

(FYI: I did this a bit wrong on the first one. I mention this so you don't do the same. I was doing things alone and was over thinking the job. I undid the strut tower nuts first and left the weight of the strut on the spindle while I removed the lower strut bolts. Don't do this! Again, I mention it only so you won't do it that way. This will put undue tension on the lower strut bolts and make them hard to remove. I wrote the DIY the way it should be done. I did it the correct way on the 2nd one and it was SUPER EASY!)

So a little trick to get the car at least back to the alignment is was at when I started... Maybe this will keep me from wrapping it around a tree on the way to get an alignment!

Just a bright colored sharpie to mark the washers spot on one side top and bottom. Also repeated it on the bolt side.

For safety, I threw a jack under the A-arm. It was only jacked up to lighly touch the a-arm. Only in case of a fluke slip on the a-arms part. Doing it alone I did not know how the car would respond... The spindle has enough parts holding it in place. Mine did not budge at all. But when leaving it diconnected over night the drivers side did sag down and needed a little lift to not strain the brake line.

Since my struts are relatively new KYBs, I did not need to use any PB Blaster, but folks with a stock set up, I advise it!

Ok time to find something big enough to get these suckers off... top bolt first, since it does not have an adjustment. Ok it turned out a 24mm or 15/16 was the magic size. Oddly both fit great. So your golden with either. I had one of each in sockets. I really need some more LARGE wrenches

Breaker bar on one side and ratchet on the other...

It took some muscle to get it going, but it was not bad. The breaker bar did the hard stuff for me. Nut broke loose and then you could turn it off with your fingers.

Then washer came off

It should come out super easy, but maybe stock has tighter tolerances then my KYBS.

Now the lower one

Loose

Off

Wow close fit... I need wrenches! LOL!

Ok once I removed the bolts, I placed the washer and nut back on its prespective bolt for safe keeping.

Sucess...

Now I gently moved the jack out of the way... Again it was not really necessary, but I did need it there overnight on the drivers side to keep the strain off the brake line.

One more little thing to remove. The brake line is attached to the strut, you need to take him loose.

I think we altered mine from stock, but it was a 10mm nut and bolt to remove

[This message has been edited by redraif (edited 09-15-2014).]

|

|

|

redraif

|

SEP 13, 02:42 PM

|

|

|

|

redraif

|

SEP 13, 03:08 PM

|

|

****FYI: The parts go back in the same orientation that they came off! So watch close as you take things apart and mark things if you need to to keep up with it!****

Time to take the spring loose. If you have a stock set up that has never been touched and no air tools, you might need a shop to help. Or at least some PB Blaster. Thank goodness I had previously tackled this thing when we installed the KYBs. So for me it was not horrible.

The struts are built so that you have another way to get them apart if you don't have airtools. The stock unit I believe has a squared part in the shaft of the strut so you can use a wrench to stop the shaft from turing. (Per fierohoho)

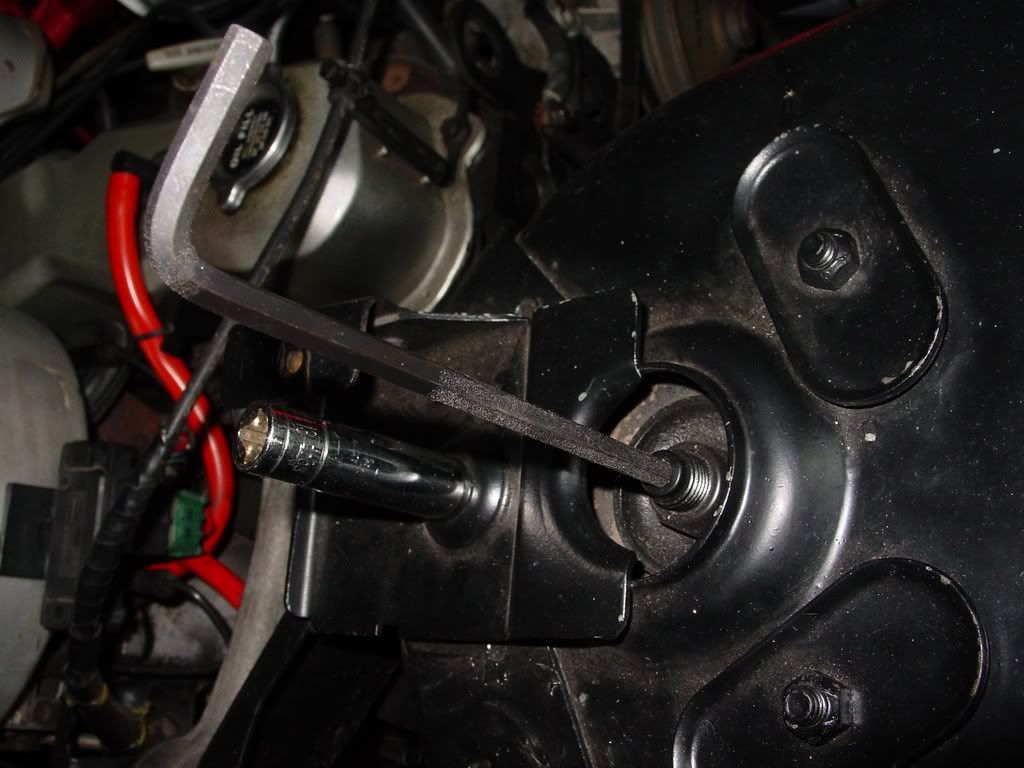

The kybs are different. There is a nut on top and a slot for a allen wrench at the top of the strut shaft. So the only way to do this without air is with an open end wrench on the nut and an allen key in the strut. I had previously measure the allen hole as a 6

The nut was too larger for my box wrench collection so I pulled out the big adjustable,

A forum member (Mike142) pointed out later in this thread that there was a better tool for the job! I had one used it at install and disassembly of the 2nd one. He was so right!

| quote | Originally posted by Mike142:

BTW, a crow's foot wrench is the best way to hold that top nut when the allen is in there. Bought a set of those years ago when I did struts on another car. They make it so much easier to undo that nut.

http://www.craftsman.com/sh...kNo=10&blockType=L10 |

|

Thanks Mike142!

I had a helper hold the unit as I loosened things on the first assembly. Again I was lucky this was a recent install and the assembly cooperated. One the second, I did it alone. Gripped it with my legs and used my thigh to brace the allen wrench and turned the wrench.

It worked. Once I got close to the release point I took the unit outside and set it on its side and finished my last few turns with it pointing away from me, windows, cars, pets, bystanders...lol! That way any tension ejecting bolts or plates should not hit me or them.

It was a bit of a let down, with just a small pop and the top nut and washer came off. The washer is sitting as it does on the unit. Cupped side up.

Here is how they sit on the unit

The spring retaining plate needed a bit of coaxing to come loose... a gentle wrap with a rubber mallet did the trick. Notice the flat side faces up when installed as an assembly

Here is the underside with the coil retainer jutting out. It helps keep things centered when you convert to the smaller diameter coli-over springs

The upper spring perch plate, note the studs face up! (fyi for install)

It was stuck on there quite well and I had to drop him on the ground and then he let go

again...top

and bottom

washer... note the domed side is up. it will be the same at install, however, the rubber bushing will seated below it.

Off in my hand. domed side up! Just like it will be installed.

Again, no dust boot... somehow it was removed when we installed the kybs. Not sure why. Had to dig them out of the attic.[This message has been edited by redraif (edited 09-15-2014).]

|

|

|

redraif

|

SEP 13, 03:19 PM

|

|

|

|

redraif

|

SEP 13, 03:25 PM

|

|

Now to grind down the weld line... the super carefull work. Steady as you go.

All smoothed. Sanded the rust spot and coated with some silver to stop the rust.

Got the sleeves and they slid on perfect... the included snap ring fixed the gap and held them tightin place! Perfect fit!

Had to stop there last night, but I did paint the gold perches a nice contrasting red that would at least tie in!

Pic of them tomorrow

|

|

|

Mike142

|

SEP 13, 04:33 PM

|

|

|

BTW, a crow's foot wrench is the best way to hold that top nut when the allen is in there. Bought a set of those years ago when I did struts on another car. They make it so much easier to undo that nut.

|

|

|

Mike142

|

SEP 13, 04:36 PM

|

|

|

|

|