|

| OEM V6 Distributor: Any Options to Reduce Corrosion / Oxidization on the POLE PIECE? (Page 1/6) |

|

Vintage-Nut

|

MAY 07, 02:04 PM

|

|

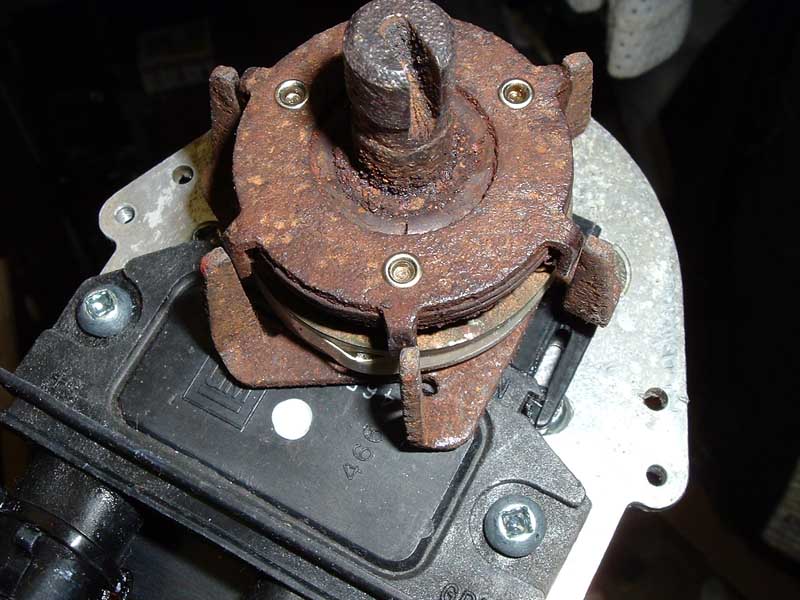

I’m servicing the OEM V6 Distributor and the stationary pole piece (the six ‘fingers’) was extremely oxidized with a mound of ‘rust’ in the bottom of the distributor housing.

With the part cleaned, I was wondering if there is a ‘better way’ to protect or diminish the decay than ‘bare metal’.

You guys know way more than I ever will learn and wanted to hear from the forum before going forward….

VN

|

|

|

Kitskaboodle

|

MAY 07, 02:34 PM

|

|

I have the same issue.

I periodically use a Dremel and wire wheel to clean them up. What also helps is to put a thin film of grease over the shaft and coil fingers.

As a bonus, grease on the shaft before putting the rotor on will help next time you have to remove it.

Kit

|

|

|

Vintage-Nut

|

MAY 07, 02:49 PM

|

|

|

Yes, I thought about a thin film of dielectric grease too…

|

|

|

theogre

|

MAY 07, 04:35 PM

|

|

Any silicone oil/grease or Permatex brake grease will prevent this and won't "eat" plastic parts.

PBG won't run under engine heat. Many silicone types will run and enough get away then rust but likely slower.------------------

Dr. Ian Malcolm: Yeah, but your scientists were so preoccupied with whether or not they could, they didn't stop to think if they should.

(Jurassic Park)

The Ogre's Fiero Cave

|

|

|

Patrick

|

MAY 07, 05:58 PM

|

|

| quote | Originally posted by Vintage-Nut:

I’m servicing the OEM V6 Distributor and the stationary pole piece (the six ‘fingers’) was extremely oxidized with a mound of ‘rust’ in the bottom of the distributor housing.

|

|

We've all been there. I posted about this 15 years ago.

| quote | Originally posted by Patrick Here:

No, this isn't some discarded distributor I found laying in a ditch in a bone yard. This is the distributor out of my '86 GT that I bought a few months ago. (The car had been sitting for six years.) I can't believe the engine ran (and actually ran well) with all this corrosion in the distributor.

I certainly didn't expect the distributor to be looking this bad!

Would "washing" it with WD40 be okay? Does anyone think that I'd be foolish to continue to use this distributor, even if I clean it up?

|

|

...and this is what my distributor looked like after I cleaned it up, as reported in my ICM heat sink thread. It continues to operate just fine (with the same ICM no less!) a decade and a half later.

|

|

|

Vintage-Nut

|

MAY 07, 10:10 PM

|

|

WOW Patrick, my distributor looked WAY better than your photos, so I think I'm luckier than others......

I brought Permatex dielectric grease for the module, so I'll put a thin film of dielectric grease on the pole piece.

I hope it will be 'better' and diminish the corrosion; I'll see at the next distributor cap/rotor change....

|

|

|

Patrick

|

MAY 08, 12:29 AM

|

|

| quote | Originally posted by Vintage-Nut:

I brought Permatex dielectric grease for the module...

|

|

Only if you don't want your ICM to last! Dielectric grease is not what is supposed to be used under the ICM.

You want to be using proper heat sink compound/thermal paste between the base of the distributor and the ICM.

However, using dielectric grease on all electrical connections is a very good idea.[This message has been edited by Patrick (edited 05-08-2023).]

|

|

|

fierofool

|

MAY 08, 08:39 AM

|

|

The oxidation inside the distributor is caused by Ozone. Ozone is created anytime an electric charge passes through air. There are minute electric sparks between the end of the rotor button and the plug wire terminals inside the cap.

On the same thought as Kitskaboodle, I coat the top of the shaft to make removal of the rotor button a little easier, except that I put a thin film of Ant-seize on it.

|

|

|

Vintage-Nut

|

MAY 08, 10:36 AM

|

|

| quote | by Patrick

You want to be using proper heat sink compound/thermal paste between the base of the distributor and the ICM.

|

|

Got it and thanks for the heads-up!

After rereading the manual NOTICE of "silicone grease", I cross out grease and added 'Hear Sink Compound' which I have a tube of Dow Corning 340

| quote | by fierofool

On the same thought as Kitskaboodle, I coat the top of the shaft to make removal of the rotor button a little easier, except that I put a thin film of Ant-seize on it. |

|

Thanks for the idea!

When I'm done with the distributor, I'll try to "Upload Media" as it be will my first attempt...

VN

|

|

|

Vintage-Nut

|

MAY 08, 01:55 PM

|

|

| quote | by fierofool

The oxidation inside the distributor is caused by Ozone. |

|

By searching the internet for "ozone in the distributor cap" - many results point to:

A) Properly coat/protect the parts

| quote | by theogre

Any silicone oil/grease or Permatex brake grease will prevent this and won't "eat" plastic parts. |

|

Check ✓

B) Better VENTING to remove the ozone faster (some marine engines use vented caps with fine screens) 'Someone' put a 1/2" hole in the cap (lower than the terminals) and saw the distributor cap and rotor life went up dramatically.

I'll look at the two stock screened vents on the base and think about widening them.....

VN

|

|

|