|

| My DIY rear Coil-over conversion (84 model)... play by play (Warning many pics) (Page 11/11) |

|

pmbrunelle

|

FEB 03, 07:20 PM

|

|

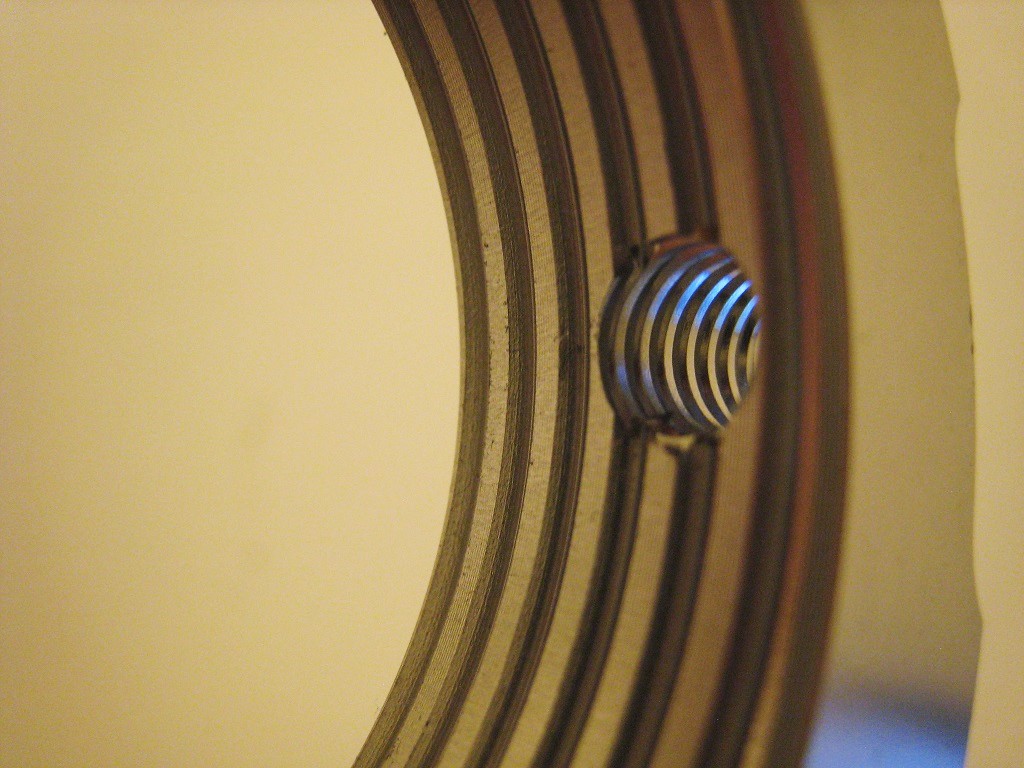

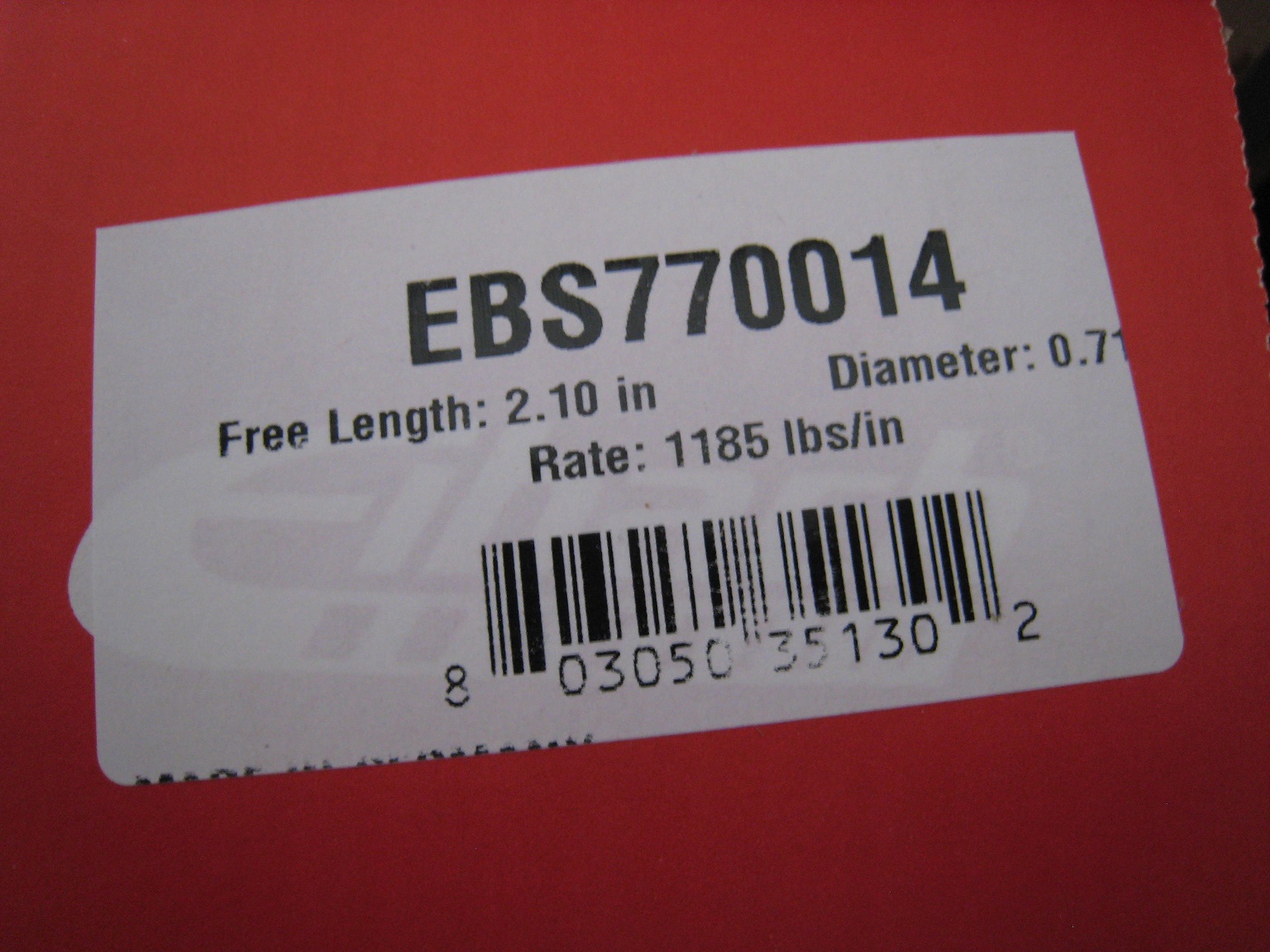

I can confirm that the Hyperco springs have a slight "barrel" shape.

Most of the coils actually have a constant, but slightly oversized diameter. It's only the end coils which are reduced in diameter to fit the standard 2.5" ID interface.

The ends are closed and ground.

I like these springs, I would recommend. I'll probably buy another pair like these (I think I goofed on my choice of spring rate).

********************************************************************************

I bought the QA1 CK60007 coilover sleeves. I am not very satisfied with this. Besides sharing what works, it is also good to share what doesn't work, so the same mistakes are not committed by others.

The CK6007 has a constant bore, with a tapered section (for wedging something) at the end:

So far, so good...

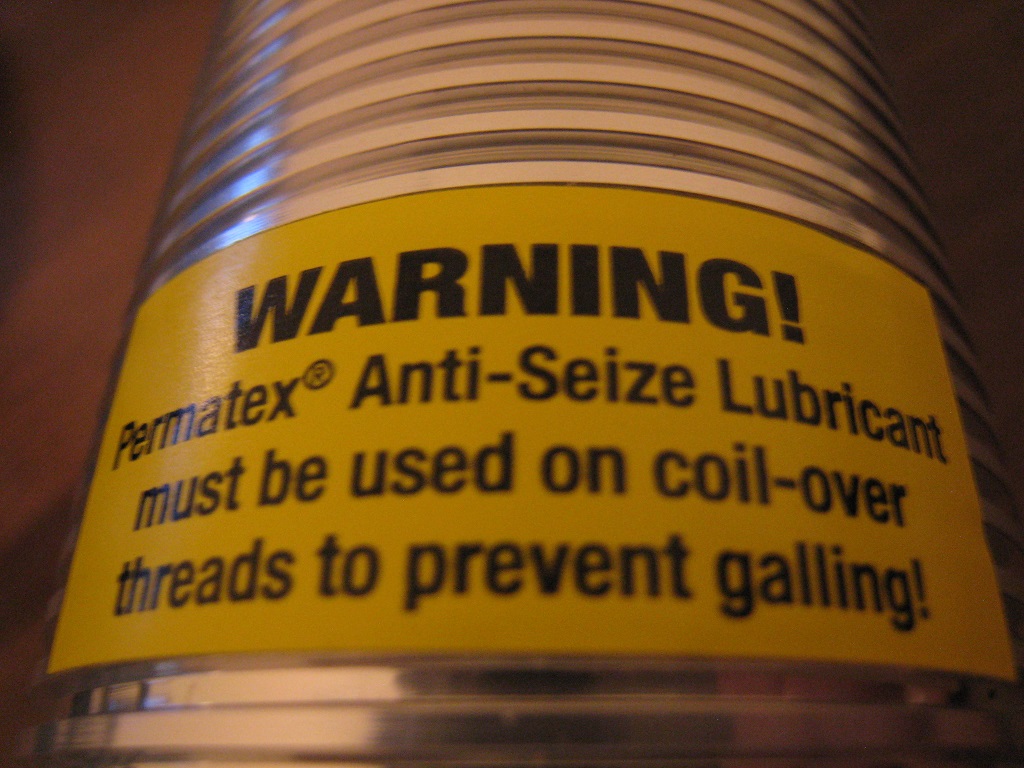

The CK6007 requires the use of anti-seize on the threads:

I try to keep my project car clean. Having a bunch of paste on the threaded sleeve will make anything that touches it dirty. Not my cup of tea.

In addition to the jam nut, the main nut has a set screw. The set screw has a soft plastic tip, which prevents marring. I like it.

The QA1 T114W spanner wrenches fit the nuts well.

There a burr in the main nut, at the set screw hole. This prevents the main nut from screwing onto the sleeve. I suppose that a Dremel job to fix this would be pretty quick.

Apparently, QA1 doesn't go/no-go their threads.

Once I try to put the CK6007 sleeve on the shock, the biggest problem is apparent.

The OD of the KYB shock is 2.000" to 2.008", depending on how I measure it.

The ID of the CK6007 sleeve is 2.100"

The sleeve is too loose, and there's not enough common area where the aluminium sleeve can bear on the weld.

A 2.020" ID would be pretty ideal, but the ID of coilover sleeves is typically not specified.

Options:

1. Buy a different coilover sleeve for a 2" nominal shock, hope it's better.

2. Make custom sleeves on the lathe. I would have to match the QA1 thread.

3. Make custom non-adjustable perches on the lathe. No trouble of trying to figure how to keep the sleeve from rotating on the shock. No risk of galled threads. I don't think I really need adjustment. Looks less modified to police taking a peek in my wheelwells.

|

|

|

pmbrunelle

|

FEB 16, 08:29 PM

|

|

They're not too bad.

They do have specs which are indicated on the box:

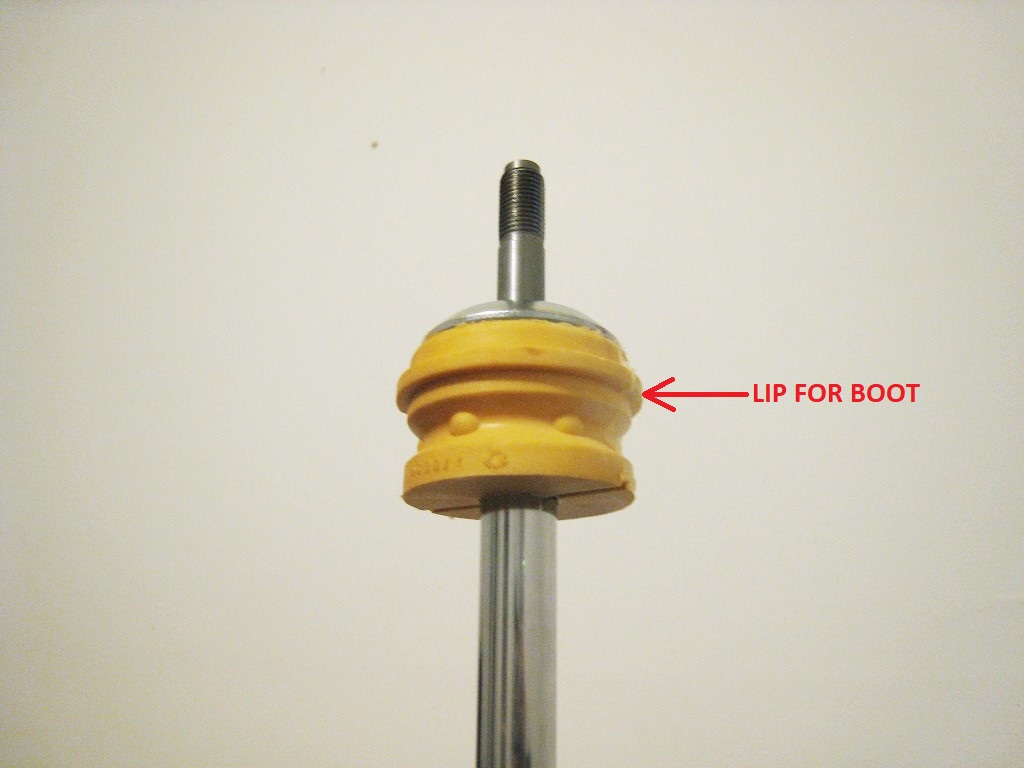

The bumpstop grips tightly enough to stay up on the shaft. It could be a bit tighter, but I think it's OK.

The dome shape on top of the bumpstop nicely nestles into the inverted bowl steel washer that goes against the strut plate.

There is a lip to install a boot (I have no idea which one). Lip diameter is 2.615", so it needs to be ground down (Dremel?) to fit inside a 2.5" ID spring.

The rest of the bumpstop measures 2.372", which should fit, especially if the spring is barrel-shaped (such as Hyperco).

The bottom of the bumpstop isn't too large with respect to the top of the KYB strut.

If the KYB strut were much smaller in diameter, then it would press on a smaller portion of the bumpstop. If the contact area is too small, then I think the true bumpstop rate will be less than the advertised rate.

********************************************************************************

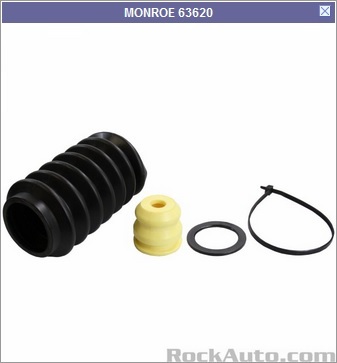

Monroe 63620, which is listed for the Fiero, might be a good solution also. From pictures, the bumpstop doesn't have a lip which would look goofy if used without a boot.

Looks like it might look more slim inside the spring. No rate specification though, or free length.

Not sure if I want to buy this one for evaluation.

********************************************************************************

| quote | Originally posted by pmbrunelle:

Options:

1. Buy a different coilover sleeve for a 2" nominal shock, hope it's better.

2. Make custom sleeves on the lathe. I would have to match the QA1 thread.

3. Make custom non-adjustable perches on the lathe. No trouble of trying to figure how to keep the sleeve from rotating on the shock. No risk of galled threads. I don't think I really need adjustment. Looks less modified to police taking a peek in my wheelwells. |

|

I went with #3, but I decided to outsource the fabrication of these parts.

If anyone wants the STEP file, I can share it with you. You probably want to wait until I have a photo with the sleeve installed and coilover assembled... I'm pretty good at not getting things right the first time.

|

|

|

pmbrunelle

|

FEB 22, 10:09 PM

|

|

Monroe 63620 specs (measured by me):

Free length: 2.00"

Outside diameter: 2.15"

Fit on KYB shaft: tight, but good.

Hardness: The Monroe bumpstop is made from a harder material than the Eibach bumpstop. My fingernail doesn't go in as deep when pushing into the surface (perhaps half the depth).

The Monroe is good because its outside diameter is good out of the box.

The Monroe could be trimmed down to a length of 1.53" in a way that would look clean, if for whatever reason you want to modify it.

The Eibach stiffness is known (visible in photo of box above), and it is a good bunch softer than the Monroe (fingernail test). If/when the car hits the bumpstop, it is good if the bumpstop is soft, so that the impact is less jarring, and the sudden change in handling characteristics is hopefully easier to manage for the driver.

The softness of the Eibach can also be considered a downside, in the sense that more movement can occur after hitting the bumpstop. Depends on the install... does your install need the bumpstop to prevent tire rubbing, or would there be still clearance with metal-on-metal (no bumpstop)?

********************************************************************************

On my own car with the Eibach, coil bind of the 10" Hyperco spring will occur with 0.85" of bumpstop squish. It would need 3800 lbs of load on the strut for coil bind to occur (which seems unlikely), so I think I'd rather run the softer Eibach than the harder Monroe.

I suppose that of all things that could limit travel, coil bind doesn't sound too bad, versus having the tire hit the wheelwell or something else happening.[This message has been edited by pmbrunelle (edited 02-22-2022).]

|

|

|

A_Lonely_Potato

|

FEB 23, 01:16 AM

|

|

|

Hey guys, a ton of good information on here! I feel kinda stupid asking this question, but which KYB struts are you using? From what I find I would assume its the #236001 Excel-G, but i would really rather make sure before i lay down money!

|

|

|

fieroguru

|

FEB 23, 02:00 PM

|

|

| quote | Originally posted by A_Lonely_Potato:

Hey guys, a ton of good information on here! I feel kinda stupid asking this question, but which KYB struts are you using? From what I find I would assume its the #236001 Excel-G, but i would really rather make sure before i lay down money! |

|

https://www.summitracing.com/parts/kyb-234005

|

|

|

LFiero67

|

MAR 07, 10:16 PM

|

|

Thanks for the info, used everyone’s posts here to put together my own. This should allow for some bigger tires when this thing hits the road again. KYB struts, Allstar sleeves, Qa1 275lb high travel springs, ABS pipe locators, KYB strut mounts. Thanks for the info, used everyone’s posts here to put together my own. This should allow for some bigger tires when this thing hits the road again. KYB struts, Allstar sleeves, Qa1 275lb high travel springs, ABS pipe locators, KYB strut mounts.

------------------

10.007 @ 135.54MPH. <-- Video

Best 60' 1.42

Best mph 138.82

Billet 6262 Precision turbo, PT1001 intercooler, ST1 cam, 140lb springs, comp pushrods, HV3, stock L32 bottom end and heads.

Old M90 XP Cam time -

11.425 @115.60

1.543 60'[This message has been edited by LFiero67 (edited 03-07-2022).]

|

|

|

Spadesluck

|

MAR 07, 10:26 PM

|

|

Those look good! Make sure you out some anti-seize on the threads of the sleeves before using. Helps not damage the sleeves.

I went with some QA1 high travels as well for my new build. Don't think I had any coil bind before but better safe than sorry.

|

|

|

pmbrunelle

|

MAR 16, 07:20 PM

|

|

| quote | Originally posted by pmbrunelle:

Options:

1. Buy a different coilover sleeve for a 2" nominal shock, hope it's better.

2. Make custom sleeves on the lathe. I would have to match the QA1 thread.

3. Make custom non-adjustable perches on the lathe. No trouble of trying to figure how to keep the sleeve from rotating on the shock. No risk of galled threads. I don't think I really need adjustment. Looks less modified to police taking a peek in my wheelwells. |

|

| quote | Originally posted by pmbrunelle:

I went with #3, but I decided to outsource the fabrication of these parts.

If anyone wants the STEP file, I can share it with you. You probably want to wait until I have a photo with the sleeve installed and coilover assembled... I'm pretty good at not getting things right the first time. |

|

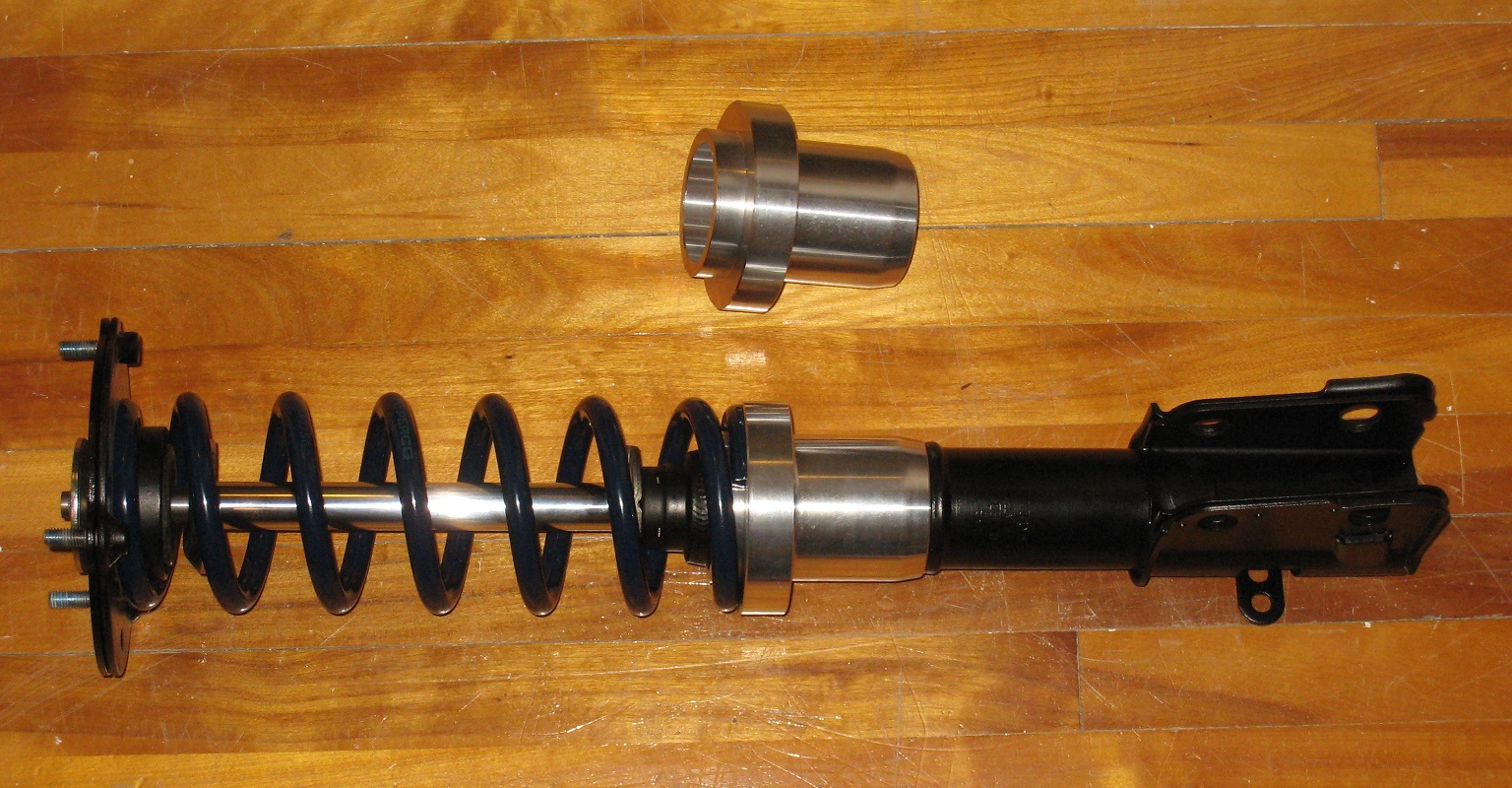

Looks like that idea worked out. The sleeve sits on the weld, with the spring perch up and out of the way.

I'm not a fan of buying aftermarket parts with missing critical information (such as the ID of sleeves). Often turns out to be a waste of time/money... but that is the reality of modifying a car.

The spring will only be preloaded some 1/4", so no spring compressor will be needed. There are enough exposed threads on the shock rod to use the nut to compress the spring.

|

|

|

jdv

|

MAR 17, 02:59 PM

|

|

|

|

pmbrunelle

|

MAR 23, 05:39 PM

|

|

I found what I think is the ideal bumpstop (my opinion, of course) for Fieros without strut bellows.

Eibach 770014:

It has the squishiness as I previously mentionned so bottoming out shouldn't be too jarring, it has a good grip on the KYB shock rod, and it has no extraneous bits needing trimming like the other Eibach bumpstop I checked before.

|

|

|

|