|

| Help with a LS4/F23 swap (Page 2/5) |

|

fieroguru

|

DEC 09, 08:29 PM

|

|

The LS4/F23 is definitely less common than the LS4/F40, but in theory it should be easier/cheaper swap based on price for the transmission and you "might" be able to reuse the stock Fiero axles... but you will want to check the passenger tripot clearance to the LS4 block. The Fiero tripots are fairly large in diameter and I know they won't clear the LS4 with the F40. If the factory tripods won't clear, then the F23 swap gets more complicated and more uncharted territory. You would need an intermediate shaft, later model smaller diameter tripots, and find the right axle length.

Turning down the LS flywheel to accept the 142 tooth ring gear and having it drilled for the pressure plate pattern works well. There was a time when you could get a new billet steel flywheel for about $65 as a factory second due to the pressure plate bolt pattern being wrong... but all those holes are removed with this modification. You could also start with a junkyard flywheel.

I wouldn't ask SPEC to make anything, their R&D attention to detail is atrocious.

LSC Performance makes flywheel for many Fiero engine swaps & they probably have the details for the LS crank pattern. They could likely take of the of Fiero flywheels, add the LS crank pattern to it and you would be golden. I suspect this solution would cost $300+

LSC Performance

25839 Jefferson ave.

Murrieta, Ca 92562

Phone: (951) 677-8895

E-mail: Tom@Lscperformance.com

The F23 clutch/pressure plate solution is hit and miss if you try to use a Fiero based clutch (stock F23 based clutches normally work 100%, but it will need to an upgraded version). Most of the Fiero clutch pressure plates will interfere with the F23 differential bulge, but some work. The issue is most of the clutch builders mix and match parts and you can order the same clutch kit 3 times and end up with 3 different pressure plates.[This message has been edited by fieroguru (edited 12-09-2020).]

|

|

|

Rotmilky

|

DEC 10, 07:40 PM

|

|

Thanks Fieroguru for the really helpful comments. It provided some nice structure to 'grease monkey 101' where we considered how things can go sideways....

| quote | Originally posted by fieroguru:

The LS4/F23 is definitely less common than the LS4/F40, but in theory it should be easier/cheaper swap based on price for the transmission and you "might" be able to reuse the stock Fiero axles... but you will want to check the passenger tripot clearance to the LS4 block. The Fiero tripots are fairly large in diameter and I know they won't clear the LS4 with the F40. If the factory tripods won't clear, then the F23 swap gets more complicated and more uncharted territory. You would need an intermediate shaft, later model smaller diameter tripots, and find the right axle length.

|

|

Oh Crapola. That's something we hadn't considered. Thanks for pointing that issue out. We dug around and found a post showing that they had to grind some material off the block at the oil pan interface to get the tripot to clear the block. They ground enough material that they started to hit the oil pan gasket. So, that didn't bode well for us using our axles directly with the F23.

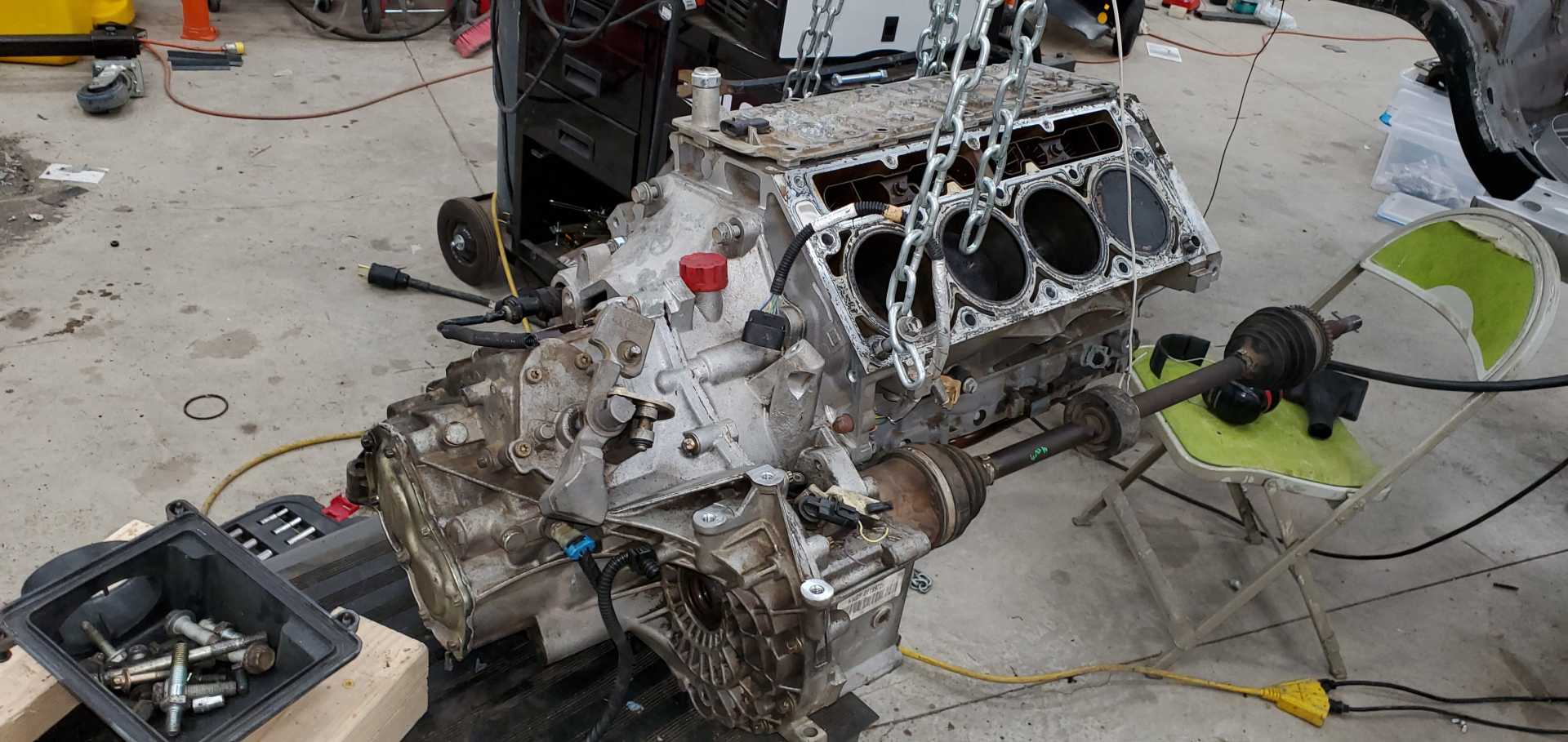

To see just how much material we needed to grind, we bolted the F23 to the LS4 and inserted the long axle into the F23.

In a bit of good fortune, we found that our axle does not currently hit the LS4. It's close...somewhere between 0.025 - 0.03" at the boss, but it clears.

As a side note, the axle I'm test fitting is actually from the 2002 Pontiac Sunfire that we took the transmission from. It looks to be identical to the Fiero axle...but I don't have a set of calipers deep enough measure the maximum diameter of the tripot.

Phew. Looks like we might have dodged a bullet.

Now to sort the clutch.[This message has been edited by Rotmilky (edited 12-12-2020).]

|

|

|

fieroguru

|

DEC 10, 08:38 PM

|

|

Don't claim victory yet... that axle is too short. The Fiero passenger side manual transmission axle is the longest one GM ever made, and it was only used in the Fieros. You will want to keep the F23 close to the stock transmission location as there isn't room on the passenger side to move the engine w/o cutting into the frame rail.

So you will need the FIero passenger side axle, test that tripots. If you run into issues, then pull both tripots apart and see if the actual axle shafts share the same spline. If so, then you can install the Fiero long axle shaft into the guts (tri-lobe section) of the tripot. Some axle mix and match, some don't...

|

|

|

Rotmilky

|

DEC 11, 04:37 PM

|

|

| quote | Originally posted by fieroguru:

So you will need the FIero passenger side axle, test that tripots. If you run into issues, then pull both tripots apart and see if the actual axle shafts share the same spline. If so, then you can install the Fiero long axle shaft into the guts (tri-lobe section) of the tripot. Some axle mix and match, some don't... |

|

Once again you prove prescient. I put the Fiero passenger axle on there and now I'm clipping that boss by about 0.1". I'll try so see if I can mix and match parts later this week to make an axle that works without grinding.

If that doesn't work, I think the easiest path forward would be to grind off part of that boss. I think I'd probably start to hit that hole in the boss, though. Any idea what it's for?

Here's a photo of the two axles side-by-side. The Fiero axle is about 40" long and the sunfire axle is about 38.5" long. The Sunfire axle is the one with the small rubber cylinder in the center. It looked like it was to protect the axle from rubbing on the frame.

|

|

|

Dennis LaGrua

|

DEC 13, 10:18 PM

|

|

Having done 3.4L, 3800SC and 4.9L swaps I rate the LS4 as a hard first swap, especially one with a manual. It is a very involved swap as you are discovering. One of the first things that you will need to do is to figure out how to mount the starter. On LS4's the starter mounts on the automatic transmission bell housing but the Getrag F23 or F40 stick transmissions do not have that. This will require some custom bracket work. You will also be swapping an engine where the ATF function will need to be disabled and if you do any mods the cam, lifter and pushrods must all be replaced. Custom motor, and trans mounts also come into play as well as fabricating a new belt routing which requires relocating the alternator.

All of these have been overcome by some talented swap guys but the key comes down to your fabrication skills. Not trying to dissuade you or be negative, Just trying to explain what you will face. ------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

Dennis LaGrua

|

DEC 13, 10:21 PM

|

|

Having done 3.4L, 3800SC and 4.9L swaps I rate the LS4 as a hard first swap, especially one with a manual. It is a very involved swap as you are discovering. One of the first things that you will need to do is to figure out how to mount the starter. On LS4's the starter mounts on the automatic transmission bell housing but the Getrag F23 or F40 stick transmissions do not have that. If Fierogurus mount fits then you are home free if not this will require some custom bracket work. You will also be swapping an engine where the ATF function will need to be disabled and if you do any upgrade mods the cam, lifter and pushrods must all be replaced. Custom motor, and trans mounts also come into play as well as fabricating a new belt routing which requires relocating the alternator.

All of these have been overcome by some talented swap guys but the key comes down to your fabrication skills. Not trying to dissuade you or be negative, Just trying to explain what you will face. ------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

cam-a-lot

|

DEC 14, 06:37 AM

|

|

Great thread- It is great that you were able to get the teenage ladies to get their hands dirty and learn these skills.... I can't even get my teenage daughters to make eye contact long enough to get off their phones.......

Something to consider is the final drive ratio on the F23. It is not really well suited for high torque motors- it was originally paired with a gutless 4 cyl motor that is almost as depressing as the 2.5 that came in your Fiero. Maybe consider doing the gear swap to the FY1 F23 of the 2010 Cobalt SS? There are some threads documenting this process here on PFF. Best of luck with the project, and congrats on raising "go-getter" teens! That is an achievement in itself!

|

|

|

Will

|

DEC 14, 09:05 AM

|

|

| quote | Originally posted by Rotmilky:

And here they are on the first day, complete in their new Carhart overalls beginning to determine what was wrong with the car

|

|

If that's actually the first day, there's a telltale in the background that you never intended to let the 4 cyl continue living in that engine bay

|

|

|

Will

|

DEC 14, 09:34 AM

|

|

| quote | Originally posted by Rotmilky:

After looking a bit closer, the F23 flywheel is certainly not a bolt on solution. The LS4 and F23 both have 142 tooth ring gears and both have 6 bolts holding them to the crankshaft. However, the bolt circle diameters are different (3.1" for LS4 vs 2.35" for F23) and the center hole diameters of the flexplate/flywheel are different (1.7" for LS4 vs 1.25" for the F23) So. the flywheel off the Sunfire is not a direct bolt on and I think if I tried to enlargen the center hole of the F23, I would get it awfully close to the bolt holes.

Would it be possible to weld the F23 flywheel holes shut, redrill it for the LS4 pattern and then make the center hole 1.7" in diameter on a lathe? My local machine shop should should be able to do that, I would think and seems like it'd be pretty cheap. The outside of the F23 flywheel looks like it'd sit 0.830" off the LS4 flange. Currently the outside of the ring gear on the flex plate it 0.835". Basically the F23 flywheel would occupy the same space as the current flexplate/ring gear. A stage 2 clutch/pressure plate rated to ~300 ft/lbs for this is about $550.

|

|

The F23 flywheel should be adaptable. The center bore may come close to the bolt holes, but the center bore is only for locating the flywheel on the crankshaft. Make sure the new bore is a VERY close fit.

The stresses are fed into the flywheel at the crankshaft bolts, not the center bore. As long as the LS4 bolt circle and material outside of it are there, you'll be ok.

Since the LS4 also uses a larger circle with the same number of bolts, you can locate the LS4 holes in between the original holes and you'll be fine.

Do check the back side of the flywheel to make sure that the machined pad that mates to the crankshaft is large enough that there is machined material outside the LS bolt holes.

IIRC the LS4 is rated at 330 ftlbs stock, so a clutch rated for 300 flbs is marginal, especially if you start "doing things" to the engine, like adding the LS2 intake I think you mentioned...

|

|

|

Will

|

DEC 14, 09:36 AM

|

|

| quote | Originally posted by Rotmilky:

I think I'd probably start to hit that hole in the boss, though. Any idea what it's for?

|

|

That's a locating hole for when GM starts to machine the raw casting. It's not necessary for anything we do with the engine.

|

|

|

|