|

| Interior Fuel Sender/Pump Connector (Page 2/3) |

|

gjgpff

|

JAN 06, 01:15 PM

|

|

Yeah, that is a concern. I'd read that page when I was just contemplating my current fix and before my current issue. My sender issue is that ever since I got the car in June 2020, the fuel gauge needle only traveled from Full, when the tank is full, to half-full and then stopped. I now believe I know what was causing the problem. I believe that, due to corrosion in sensor and/or ground wires, there was residual impedance in the line. This impedance, lets say 30-50 ohms is sufficient to keep the needle at half way, even if the sender's float is at the bottom of the tank. I believe that my fix, which is imperfect, has probably mitigated the residual impedance, at least a little and maybe a lot because the needle is now at 1/8 full and there's about 2-2.5 gallons in the tank. However, I still have the main problem, which is that the fuel pump isn't working.

I'm contemplating the following now instead of getting the Fiero Store Sender:

If I am able to figure out why my fuel pump isn't starting, even if it isn't due to anything in the tank I'd like to do the following:

1) Replacing the connecting wires with that setup from Racetronics, it looks sweet.

2) The steel pressure line from the pump out of the tank was severely pitted where it was joined to the pump by a short length of submersible (hopefully!) fuel line. I'd like to cut that steel line above the pitting and replace it with a short new length of 3/8" mild steel tubing. I have a buddy who makes a living at welding/brazing, etc. I mitigated the pitting with rust removal and JB Weld and some wet sanding to smooth out a sealing surface, but if I could attach new line I'd eliminate that potential source of issues.

What do you think of 2? Is it realistic to weld/braze a short length of 3/8" mild steel fuel line there? I guess I could ask my buddy. I will update this with pictures tonight.

Are the fixes I'm contemplating going to get me a sender/pump apparatus that's as good as the Fiero Store's?[This message has been edited by gjgpff (edited 01-06-2022).]

|

|

|

theogre

|

JAN 06, 02:19 PM

|

|

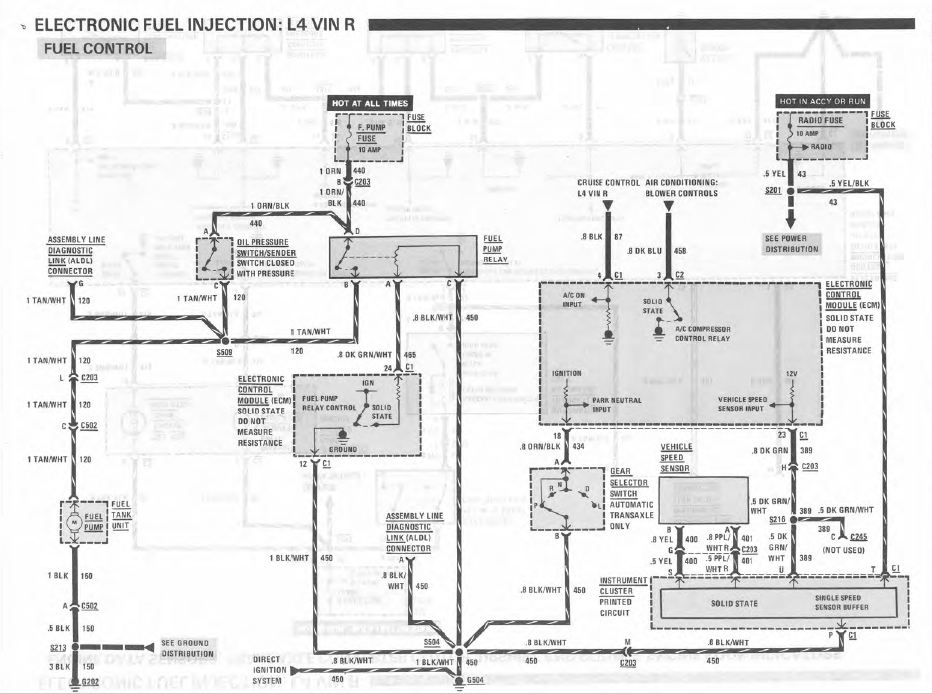

ECM can "die" and seem to work via CEL/MIL.

So You need to check output line from ECM to FP Relay turns on.

Swap AC clutch and FP Relay if have AC.

Relay can have burn contact etc...

OP FP switch should be On < 10psi but may has wiring problem etc.

Weather Pack C502 should be ok because can't get power to aldl g.

|

|

|

V8Steve

|

JAN 06, 03:22 PM

|

|

2) The steel pressure line from the pump out of the tank was severely pitted where it was joined to the pump by a short length of submersible (hopefully!) fuel line. I'd like to cut that steel line above the pitting and replace it with a short new length of 3/8" mild steel tubing. I have a buddy who makes a living at welding/brazing, etc. I mitigated the pitting with rust removal and JB Weld and some wet sanding to smooth out a sealing surface, but if I could attach new line I'd eliminate that potential source of issues.

What do you think of 2? Is it realistic to weld/braze a short length of 3/8" mild steel fuel line there? I guess I could ask my buddy. I will update this with pictures tonight.

Are the fixes I'm contemplating going to get me a sender/pump apparatus that's as good as the Fiero Store's?

[/QUOTE]

Given the amount of labor to remove and reinstall a tank along with consequences of shortcuts, I'm in favor of replacing the entire top piece. I went through this a few years ago with pump problems, sender problems, melted connector problems, relay problems, etc. Even though I got to be proficient at draining the tank, removing, and reinstalling it, I finally resorted to top quality components and tested everything on the bench as well as under the car before actually installing it in place. My budget allowed it and I realize this approach is not for everyone.

|

|

|

Rexgirl

|

JAN 06, 05:01 PM

|

|

|

The tan/white wire in the ALDL connector sends voltage directly to the Fuel Pump's positive terminal (through a connector on the firewall under the rear window). The pump's ground wire runs from the pump to a ground between the seats at the rear of the center console as Ogre wrote. If power is applied to the tan/white wire, and the pump has a good ground (and the pump itself is good, of course), it should run. [This message has been edited by Rexgirl (edited 01-06-2022).]

|

|

|

gjgpff

|

JAN 06, 05:59 PM

|

|

| quote | Originally posted by Rexgirl:

The tan/white wire in the ALDL connector sends voltage directly to the Fuel Pump's positive terminal (through a connector on the firewall under the rear window). The pump's ground wire runs from the pump to a ground between the seats at the rear of the center console as Ogre wrote. If power is applied to the tan/white wire, and the pump has a good ground (and the pump itself is good, of course), it should run.

|

|

Please forgive my ignorance, I'm only just now getting to grips with the electrical aspects of the car. I think you are suggesting that I need to turn the key to the first position and run a wire from, say, the cigarette lighter to the port "G" (usually the top/right location) on the ALDL and listen for the fuel pump, right? My reading of the schematics suggests that the fuel pump relay is between this "G" location and the actual fuel pump, is this correct?

1) If the cigarette lighter is the right approach, how should I rig up a wire? Any suggestions? I could use a small 12V battery but that may not have enough current to really get the pump going, right?[This message has been edited by gjgpff (edited 01-06-2022).]

|

|

|

theogre

|

JAN 06, 06:33 PM

|

|

Yes, can test FP by putting "12v" to aldl G but make sure is really G.

Aldl can be installed w/ "key" up or down and that affects pin layout.

See my Cave, ALDL/ALCL

Many use cigarette plug.

If you short out cig plug trying to this, might blow the bat fuse or other problem...

FP draws ~ 7-10a.

Bat fuse is 20a

Safer is likely pull the socket (2 screws) to pull power plug off back.

See my Cave, Lighter

|

|

|

Rexgirl

|

JAN 06, 06:35 PM

|

|

| quote | Originally posted by gjgpff:

Please forgive my ignorance, I'm only just now getting to grips with the electrical aspects of the car. I think you are suggesting that I need to turn the key to the first position and run a wire from, say, the cigarette lighter to the port "G" (usually the top/right location) on the ALDL and listen for the fuel pump, right? My reading of the schematics suggests that the fuel pump relay is between this "G" location and the actual fuel pump, is this correct?

1) If the cigarette lighter is the right approach, how should I rig up a wire? Any suggestions? I could use a small 12V battery but that may not have enough current to really get the pump going, right?

|

|

Yes, you should be able to use power from the cigar lighter, which is hot/live all the time. The lighter is protected by a 25 amp fuse (along with the radio, among other things), but obviously be careful with a live 12 vdc wire. Perhaps use an 18 gauge wire and an insulator sheet over the console metal? Also, it may be easier to access the cigar lighter's wire by disconnecting it from the lighter housing.

You might wish to leave the ignition off, to simplify your first pump test. I would suggest making your initial ALDL connection brief, just a second or two, or long enough to hear if the pump is running. Doing an ohm test before applying power would be a little wiser, still, just be ready to disconnect your jumper wire if needed.[This message has been edited by Rexgirl (edited 01-06-2022).]

|

|

|

gjgpff

|

JAN 07, 12:29 AM

|

|

All,

I measured the impedance between the "A" (Ground), and "G" (Fuel Pump) ports of the ALDL and it's consistent at 2 ohms, so I got that going for me, which is nice.

I then unscrewed the retaining plate on the cigarette lighter and, when I disconnected the 12V orange wire, I was able to put an alligator clip on the orange wire's connector. I connected to the copper wire I stuck in the "G" (Fuel Pump) port of the ALDL with an alligator clip on the other end from the 12V source, and I could hear the fuel pump running. I did this for a few seconds two more times to make sure, hearing the fuel pump run both times. After that, I pulled my stub copper wires, connected the cigarette lighter back up and screwed the cover plate back on the ALDL interface. I tried the ignition and got the same result, crank and no start.

So, now I know that my fuel pump is probably both running and fairly well connected up. I'm thinking the next step is to see if there's an issue with the fuel pump relay.[This message has been edited by gjgpff (edited 01-07-2022).]

|

|

|

Rexgirl

|

JAN 07, 03:54 AM

|

|

That's good news that your pump is running. Hopefully the pump is delivering adequate fuel volume and pressure.

Yes, it sounds like you may have both a failed relay, and oil pressure switch. Both provide power to the fuel pump (at least in the 1987 Duke according to my '87 FSM), although the engine can run with only the FP relay (or OP switch).

[This message has been edited by Rexgirl (edited 01-07-2022).]

|

|

|

gjgpff

|

JAN 07, 12:41 PM

|

|

Thanks! Yeah, it does look like it's the relay and the oil pressure sensor. In fact I strongly suspect that the FP relay hasn't worked in all the time I've had the car because I have always had to crank it a lot in order to get it to start and it always starts when I see the oil pressure get past ~40 to ~50 on the gauge. I'm going to try to get the relay to work first. Apparently it may not be the best thing in the world to rely on the oil pressure sensor to supply power to the fuel pump:

https://www.fierofocus.com/...sails/OilSensor.html

I guess you live and learn. The relays should be here tomorrow.[This message has been edited by gjgpff (edited 01-07-2022).]

|

|

|

|