|

| Dawg Mod Fail (Page 2/2) |

|

cvxjet

|

FEB 21, 03:12 PM

|

|

I have to tell you- probably not; He is 78 years old and has Diabetes, so he lucky to just be alive.

He welded my intake, and also my custom "B" pillars....I want to do a hex-grill covering for the tail lights with slot trailer LED lights behind in the blacked out cavity....But A) It is hard to get everything designed/aligned, etc...and B) I am not sure he can even do that bit of welding anymore...

[This message has been edited by cvxjet (edited 02-21-2023).]

|

|

|

82-T/A [At Work]

|

FEB 21, 03:38 PM

|

|

| quote | Originally posted by cvxjet:

I have to tell you- probably not; He is 78 years old and has Diabetes, so he lucky to just be alive.

He welded my intake, and also my custom "B" pillars....I want to do a hex-grill covering for the tail lights with slot trailer LED lights behind in the blacked out cavity....But A) It is hard to get everything designed/aligned, etc...and B) I am not sure he can even do that bit of welding anymore...

|

|

That looks pretty sweet CVX! I like the way the back came out.

I'm hesitant to modify my existing manifold since it's an 87-88 manifold (original) with the drilled FIERO words, rather than the 85-86 with the sticker. I may have a spare, but the idea of cutting into it just seems crazy! I've welded many times before with a mig welder, and I'm pretty comfortable with it, but never with aluminum. I think I'll just have to do some research. I don't have my car to look at, but is there any issue with clearance with the bump out under the neck? I can't remember if it gets in the way of a harness, the fuel rail, or anything else?

Thanks!

|

|

|

zkhennings

|

FEB 21, 03:42 PM

|

|

Get a MAPP gas torch from Home Depot, way hotter than propane.

Clean up your paint better in the area you want to bond. Clean it really well, and use the torch to burn off any impurities in the cast Al.

And chuck that intake in the oven prior to brazing, it will make all the difference. Very hard to get the brazing area up to temp otherwise. The Al brazing rod will work just fine.

You can always bring it somewhere and pay them to Tig it if you have no luck, but I bet it is just too cold.

|

|

|

cvxjet

|

FEB 21, 05:27 PM

|

|

That taillight mod is just a mock-up......I have not done it yet...Really difficult to make a frame that fits and secures...Then I have to bend the hex-grill to fit that frame- for welding.

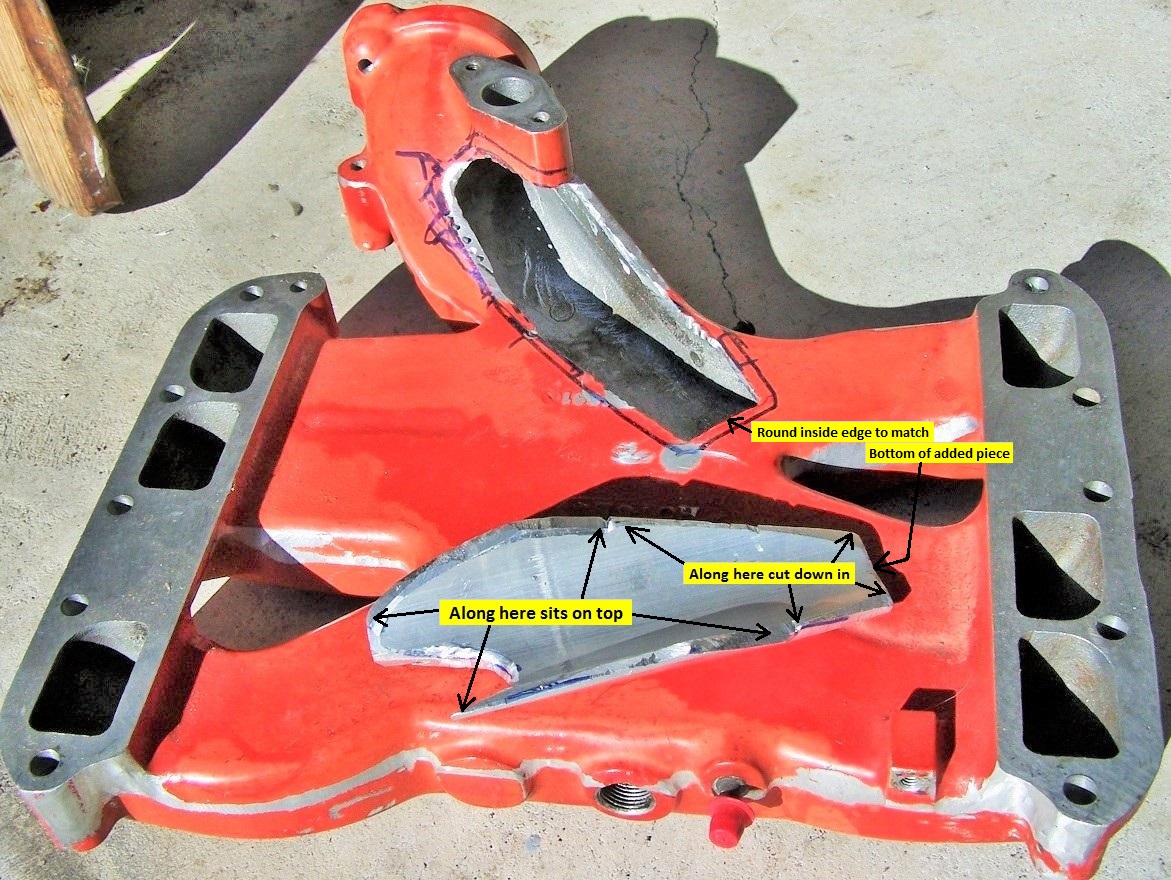

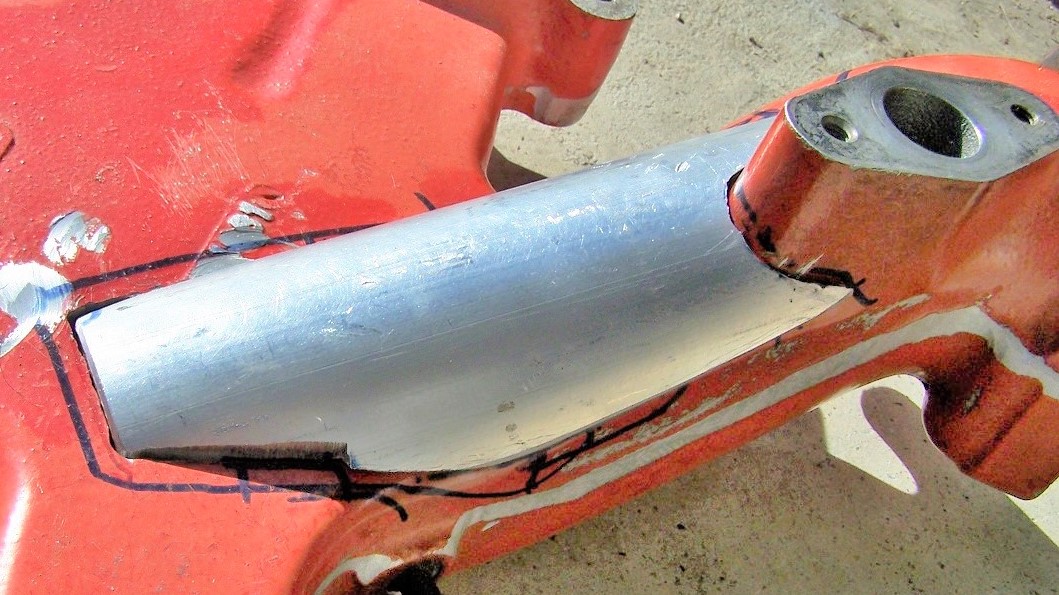

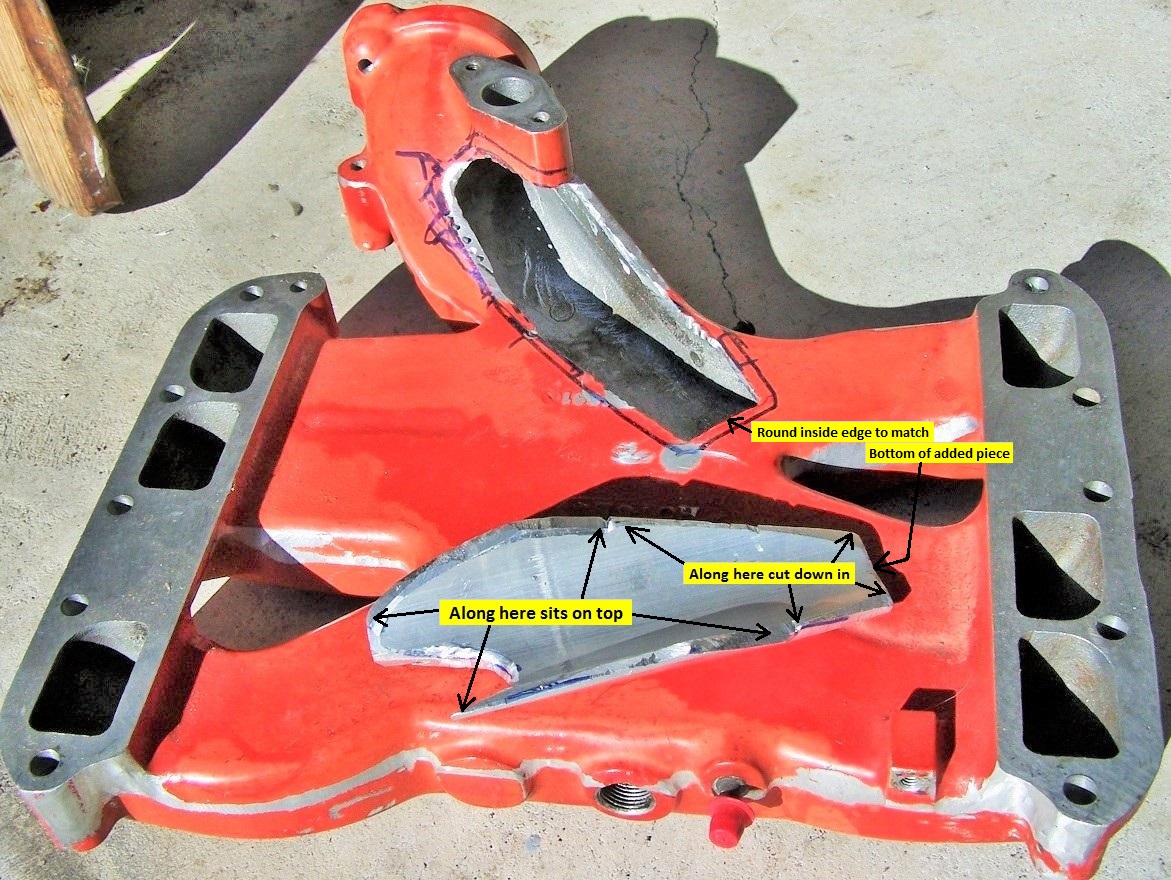

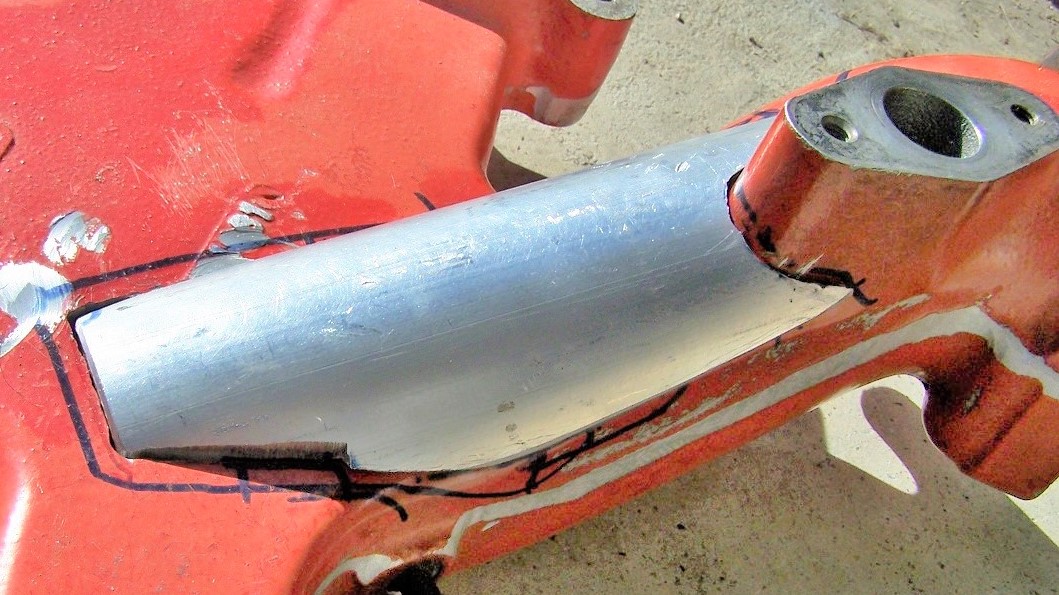

The intake manifold; I grabbed an extra manifold (87 GT) from the junkyard.....then bought a piece of aluminum tubing- cut it in half, and then spent over a year slowly carving the manifold and the half-round to fit together. It fit absolutely perfectly (Except around the EGR fitting (On the inside)....After my buddy welded it, I used a rotary file on an extension to grind a few spots smoother inside.

|

|

|

Notorio

|

FEB 21, 06:36 PM

|

|

| quote | Originally posted by cvxjet:

|

|

What about a little side business where you sell the templates to us in the Mall? One for where to cut the manifold, another for where to cut the pipe. Include recommendations for surface prep. then we can take the pieces to a local shop to to the welding. I'm guessing it would just be an hour of shop time. Your thoughts?

|

|

|

cvxjet

|

FEB 21, 07:43 PM

|

|

You know....A pattern of the shape of the cut-out on the manifold would have been very schmart.....But I only use my head for a "Hat-rack"....

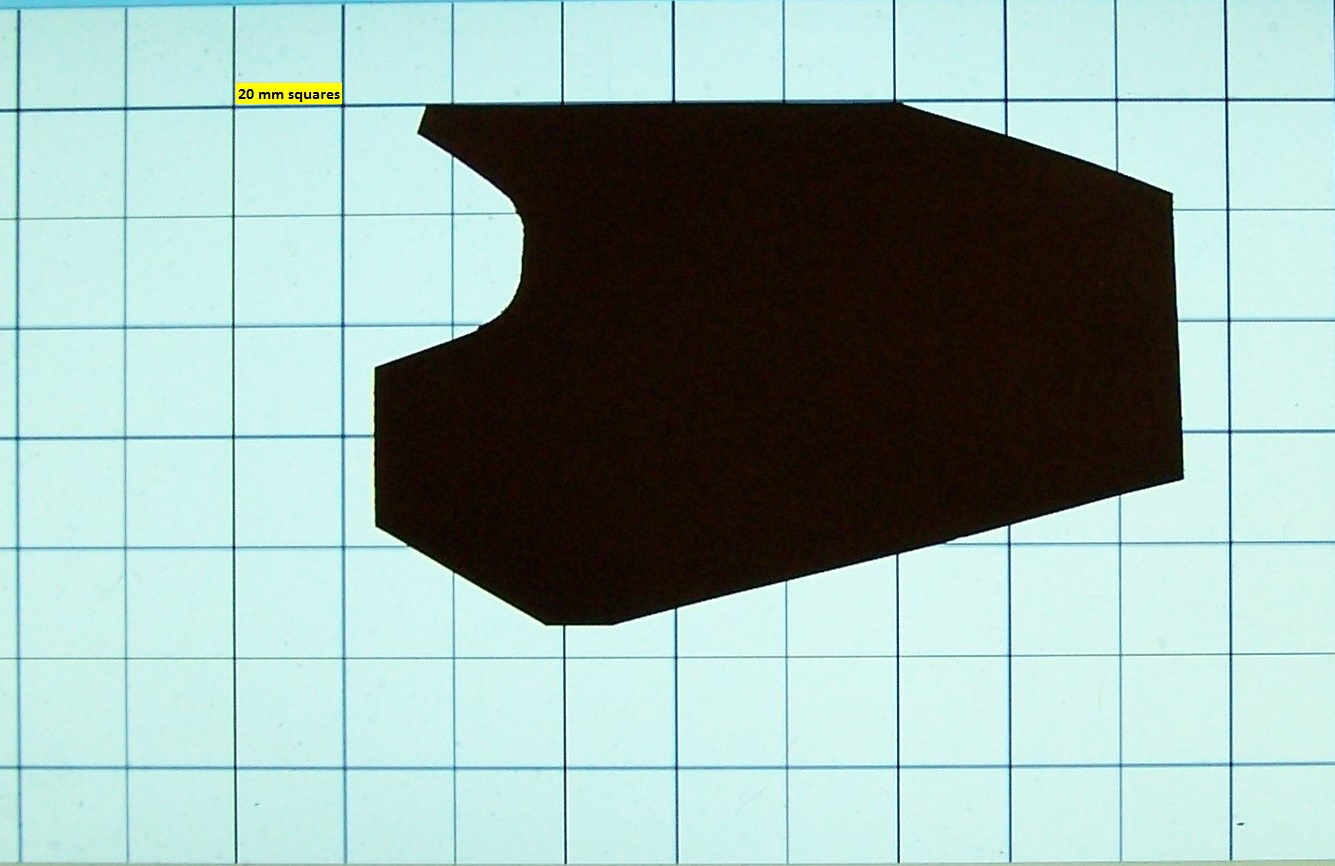

Here is the pattern to use for the tubing- just wrap it around a piece of aluminum tubing, mark and cut; Some of the edge is cut vertical, and some is horizontal.

To "french" it into the manifold, you'd have to cut slowly- leave some metal beyond where you >>think<< you should cut, and then grind it to actually fit. I used drills, a Dremel (Both grinding and cutting) and even some hand-filing.

Here is a link to the write-up I did with all the info (2" diameter aluminum tubing with 1/4" wall thickness); https://www.fiero.nl/forum/Forum2/HTML/143875.html

One important thing to reNember; Count your fingers, both before and after (I still have six and a half fingers left (Or was that right?)

[This message has been edited by cvxjet (edited 02-21-2023).]

|

|

|

Notorio

|

FEB 22, 12:31 AM

|

|

|

Many thanks! I had forgotten about your original thread (that I had posted in, no less.) So, which one of you amazing fabricators out there can do the public service of creating the matching manifold cutting pattern?

|

|

|

|