|

| Super Duty Four Rebuild (Page 2/5) |

|

Raydar

|

DEC 09, 10:50 AM

|

|

Looks like a fun project.

Since the engine seized from non-use, I would be inclined to dribble some ATF (or maybe even Kroil) into the spark plug holes, and let it sit for a few days, to see if it might free things up.

Would be a shame to tear down a low mile engine, unless that was your plan, regardless.

|

|

|

FieroWannaBe

|

DEC 09, 12:48 PM

|

|

I'm already way past that point of trying to free the block up.

I don't think ATF would have saved it, I have "bigger" plans too.[This message has been edited by FieroWannaBe (edited 12-09-2022).]

|

|

|

FieroWannaBe

|

DEC 09, 02:02 PM

|

|

In February of 2016 I trailered the car home, during a snow storm, which was quite an adventure. I changed the wheels to some that at least could hold air for a while so i could push it around, and the car sat while I devised a plan (over the course of 6 years)

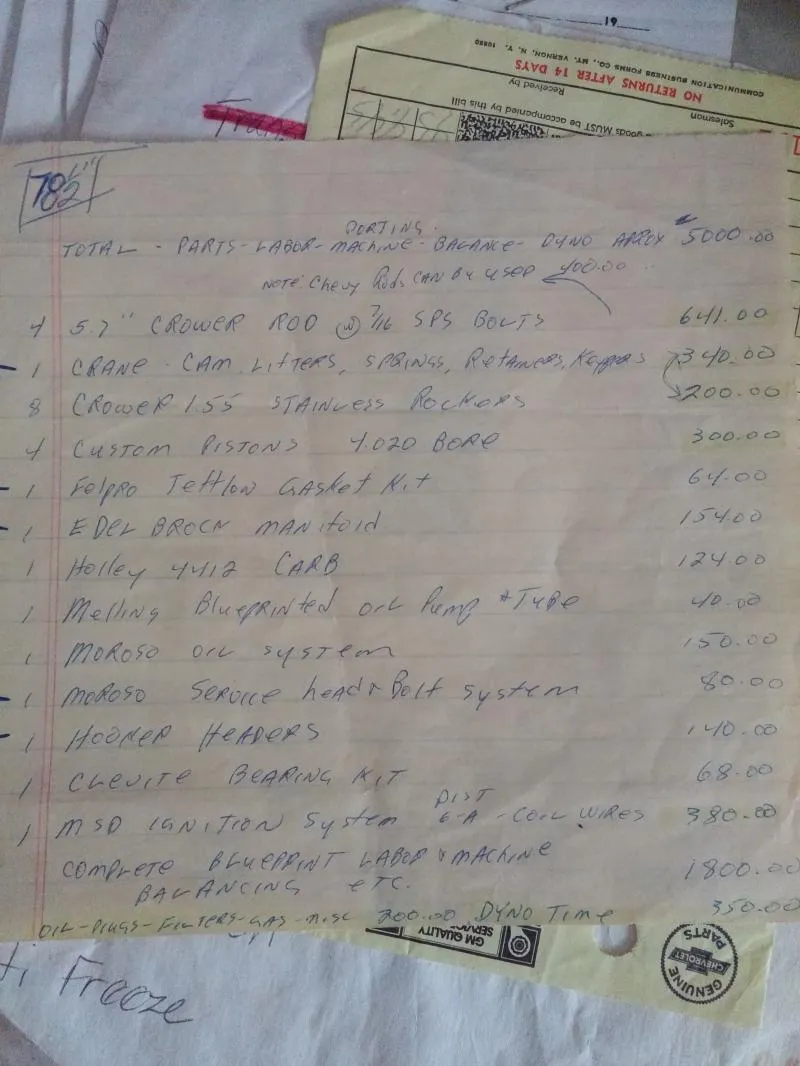

All the documentation was gone through, and after tearing down the engine this is the list of all the parts I can identify that the car had when I bought it:

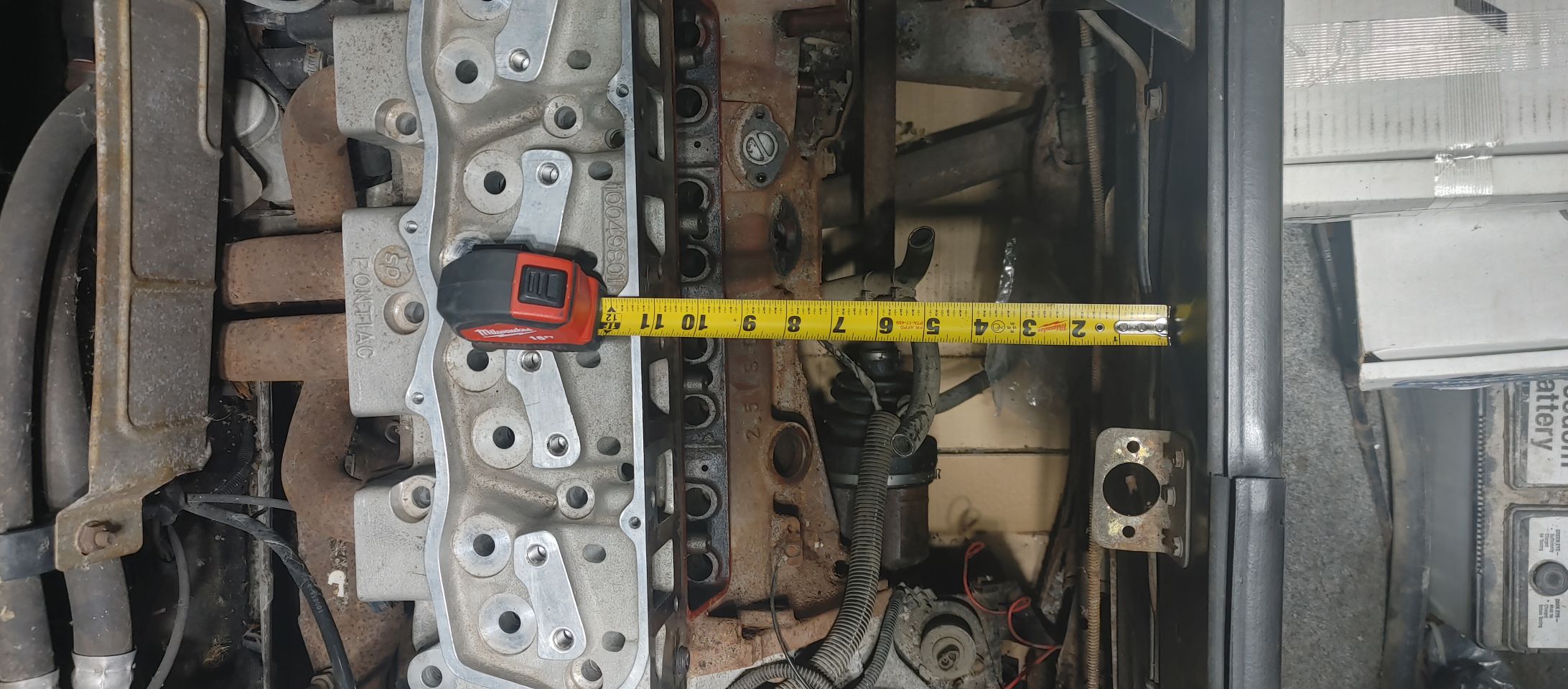

- 10027633 Super Duty 2.5 Block

- 10027779 3.25" Stroke Super Duty Crankshaft

- 10031323 Super Duty Iron w/EGR head

- 10031328 Super Duty Build Package

- 10031327 Super Duty Rocker Cover

- 12309677 Super Duty Water Pump

- 1109533 Starter

- 11566 Manley Intake Valves

- 11557 Manley Exhaust Valves

- Lunati Roller Rockers 1:7,

- 8005 Isky Springs

- 347-ST Isky Retainers/ Isky Keepers

- Isky Spring Cups

- SP295-522 Lunati Camshaft

- 54-11 Ross Pistons

- .927 Lightweight Pins

- 9941 025 RIngs

- F-91005B CrowerRods

- CB1285P Rod Bearings

- MS616P Main Set

- Custom Main Straps

- 0-1850 Holley Carb

- 45-224 Choke Kit

- 72800 Plug Wires

- 72160 Wire looms

- Melling Blueprinted Oil Pump + Tube

- Moroso OIl System

- Moroso Service Head + Bolt system

- Hooker Headers

- MSD Ignition System, SD4 Distributor, SD4 Ignition Module, Blaster Coil and Wires

- Quartermaster Twin Disc Clutch

- Koni Shocks/Struts

- Lowering Springs

- Rear Sway Bar

- Centerline 16x8 Wheels

- Front Air Dam

- Over-roof air scoop with air filter bump out.

|

|

|

StreetRod4

|

DEC 09, 02:42 PM

|

|

|

I believe that may be an extremely rare roof scoop. From what I remember about RRunners car domain, only 2 we're made for the race cars but they were not allowed by the sanctioning body to run them iirc. Car looks great! I remember missing out on bidding on that one, it wasn't far from me

|

|

|

FieroWannaBe

|

DEC 09, 03:29 PM

|

|

| quote | Originally posted by StreetRod4:

I believe that may be an extremely rare roof scoop. From what I remember about RRunners car domain, only 2 we're made for the race cars but they were not allowed by the sanctioning body to run them iirc. Car looks great! I remember missing out on bidding on that one, it wasn't far from me |

|

I probably have only seen a handful of cars with the roof scoop that had the air-cleaner bump out, it may very well be a rare piece.

It was functional on this car, however the piano hinge rusted out during disassembly.

There was a 14" airfilter under the scoop, and the builder used a shortened Fiero hood prop to hold it up in the raised position, with the hinge at the rear of the scoop.[This message has been edited by FieroWannaBe (edited 12-09-2022).]

|

|

|

Raydar

|

DEC 09, 03:29 PM

|

|

Quite the interesting list.

And yeah... driving on snow is fun. Towing a trailer has to be just waaaay too much fun.

|

|

|

FieroWannaBe

|

DEC 10, 12:49 PM

|

|

Currently I have a pile of parts I've collected for his rebuild.

The old pistons and connecting rod just arent a sound design in my opinions and the really beat up the bores on this block. It had 5.700" rods, this made the piston's compression height very tall. The pins where very close to the bottom of the bores.

I still have to go through and clean the block up before sending it across town to the machine shop.

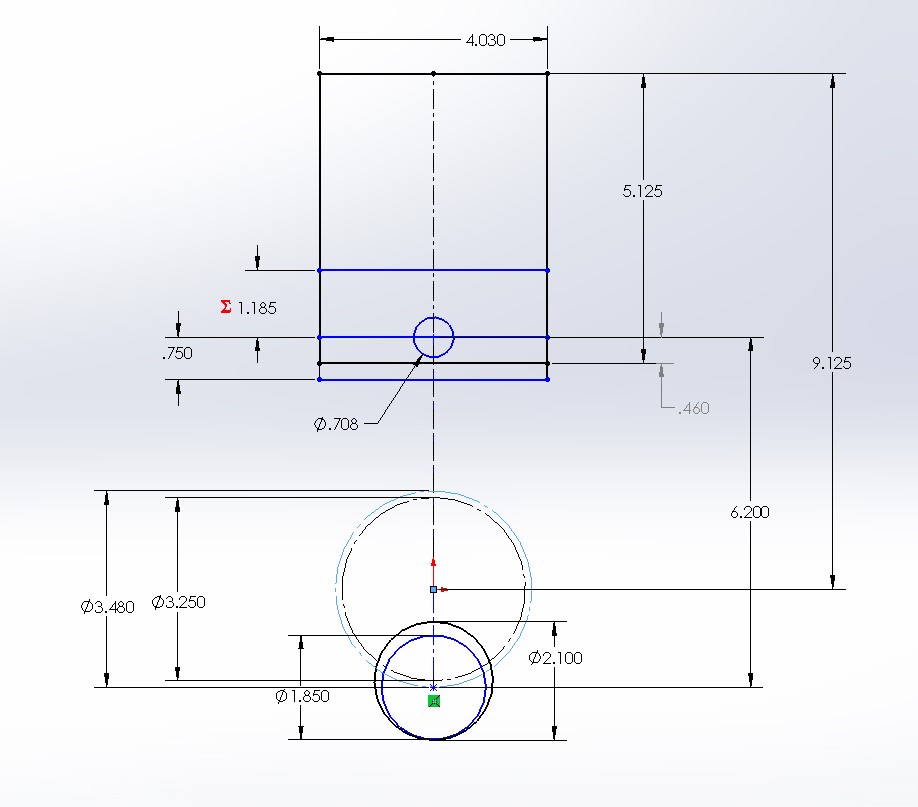

The plan right now is too use some 6.200" connecting rods that have a 1.850" pin diameter (ex nascar parts from eBay), have the 3.25" SD4 crankshaft offset ground to 3.48". I will have the block bored enough to cleanup the worn bores. This will create a 177 cu in motor. All this requires custom pistons.

I have a brand new '801 aluminum head that I hope will use the valves, rockers and springs from the iron head.

I would like to find a new higher lift camshaft, these heads flow really well past .500 lift. The current cam is a little short compared to the race hyd tappet grinds from Isky and Lunati.

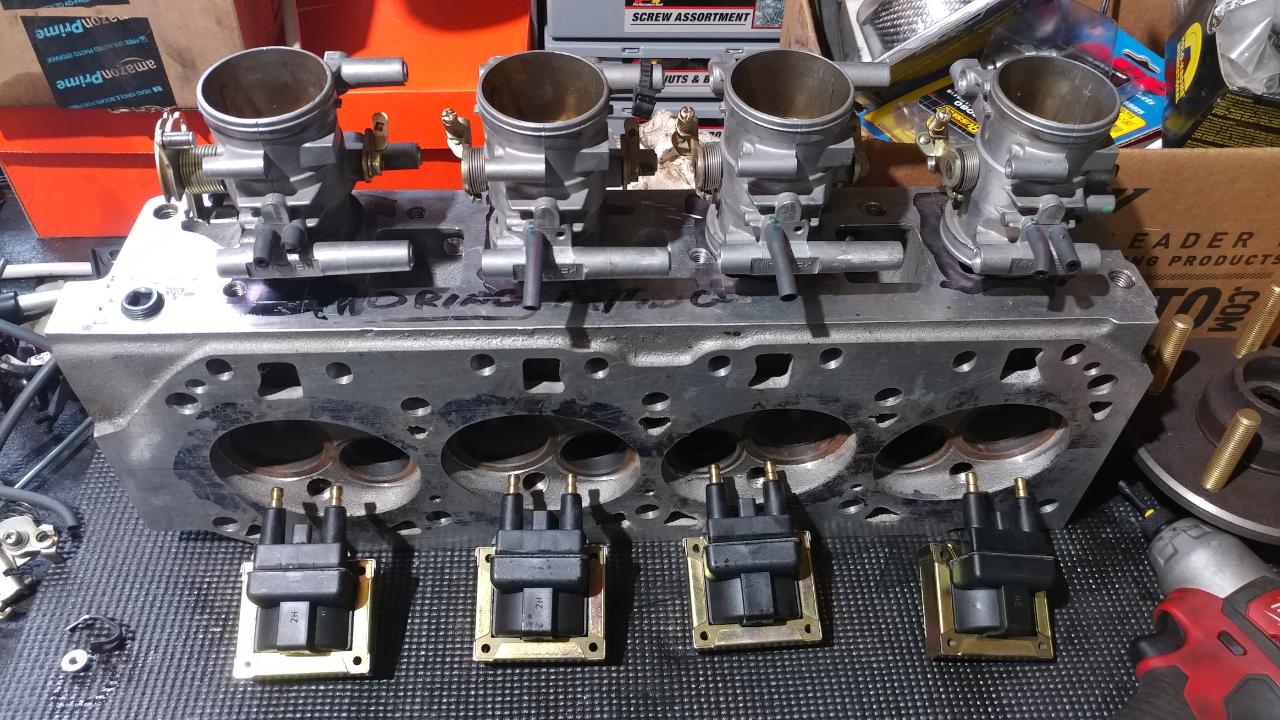

I will have fabricate a new intake to use some 48mm DCOE pattern throttle bodies I got from Amazon, where the trumpets will exit the decklid under the roof scoop. This engine will be converted to back EFI, and I will use a distributorless waste spark ignition.

The header will be replicated, but in a larger 1 7/8 primary diameter.

The car has a factory exhaust system. That needs to be replaced with a 3" system.

If you notice the pile of oil pans on the background, I am also assembling a dry sump oil system.

|

|

|

FieroWannaBe

|

DEC 13, 10:24 AM

|

|

The engine as built in 1985 had a 3.25" stroke and 4.02" bore, 165 Cu In, or 2.7L. It had forged pistons and 5.7" forged rods from Crower. They appear to be a SBC application as they have an offset.

The short rod, combined with the 9.125" deck height, and 5.125" cylinder length, bring the pin centerline to .075" above the bottom of the cylinder bore. This combination of parts was recommended at the time! this geometry would likely lead to piston rocking at the bottom of the stroke, and excess force on the skirt.

The bores do show wear from scuffing, as do the skirts.

This is the reason I am going with a set of 6.200" rods. The longer rod will place the piston pin higher in the cylinder at full stroke, which will help to prevent rocking of the piston.

The least expensive option I could find for connecting rods over 6" were used nascar rods. The set of 8 I receieved are Pankl rods, 6.2" and the big end diameter (the crankshaft pin) are 1.850, This has become a popular size for race engines (IRL) and racers are using this size on SBC and other V8s to lower friction and mass.

The used connecting rods I found where $90 for a set of 8, included the wrist pins, which are DLC (casidiam) coated.

- They are 6.200" long, 1.975" big end bore (for 1.850" bearings CB-1798H-1, $75 on eBay also) 0.903" wide.

- The Small end is .700" wide, with a .708 Pin Diameter, these pins are common sizes in motorsports engines.

- They have 3/8" rod bolts and weigh 537 grams (that's very light)

The non conventional specification will have to use custom pistons, which is hard to avoid when building a SD4, since it really should have flat top pistons without valve reliefs. This is becuase the valves have no incline unlike almost all V engines and OHC engines.

By downsizing the connecting rod crank pin diameter, I can have the crankshaft ground to a different stroke, The SD4 and Iron Duke where designed with a 2.1 crankshaft pin diameter, that leaves 0.25" inches of material to relocate the new size crank pin centerline in, accounting for .01 of material for cleanup and error, that leaves a maximum stroke of 3.48", this new combination places the piston pin .460 above the bottom of the cylinder bore.

What does this mean for my compression ratio?

With the original bore and stroke the cylinder displacment was 676 cc

The SD4 head gasket, 4.1 bore dia x .039 thickness = 8.44cc volume)

The iron head volume was measured at 55cc

I assume the engine has a 0.0 deck clearance, as this is recommended in the build manual.

This engine was most likely at 11.7:1

My rebuild will likely be a 4.03" bore and 3.48" stroke (178 Cu In, 2.9L)

The new cylinder Volume would be 727cc

The new head I have has an advertised 67cc chamber, I will shoot or a finished size of 64cc

The new pistons will probably at 0.00 deck height

The stroked compression ratio will likely be at 11:1

|

|

|

82-T/A [At Work]

|

DEC 13, 07:44 PM

|

|

|

Very cool build! I look forward to seeing all of your updates!

|

|

|

FieroWannaBe

|

DEC 14, 02:59 PM

|

|

In March of 2015 I bought a brand new, unfinished 10049801 aluminum SD4 head on ebay, shipped for $680. I'm not so sure I got a great deal, but it was cheaper than the aksing price at the time. I also think it will lighten the car up and add power.

Last month I discovered there are a lot of changes made to the SD4 engine for the aluminum heads that arent talked about. Ill follow up with more details on that, and I'll show how the iron head is great compared to a production car Iron Duke head, and how racing really made the aluminum head into a serious race head.

This head has a sales description of:

10049801 — Super Duty Four High Port Special Aluminum Cylinder

Head

This version of Pontiac’s Super Duty four-cylinder aluminum cylinder head's

are designed for maximum-effort competition engines. The intake runners

and water jackets are raised .670" to improve flow. In the Special High Port

casting, the two center intake ports are moved .800" closer together to

straighten the path to the valves. Both heads’ rocker cover rails are raised

.300", and the exhaust ports are raised .600". The valve centerlines are

relocated to unshroud the valves, and the rocker stud holes are moved to

match the new valve locations. The valve seats will accept 1.94–2.08" intake

valves and 1.60–1.625" exhausts. The combustion chamber volume is 67cc.

Technical Notes: Valve guides are supplied but not installed. A template is

provided for redrilling headers to fit the revised exhaust flange bolt pattern.

An intake manifold must be fabricated to fit the High Port Special's port

spacing.

I am still finding the right valvetrain parts to finish this head, or I may use the existing valves/springs from the Iron head.

For the intake, I started my plan with some GSXR1300 throttle bodies, however they are only 42mm ID, which is undersized for the airflow of any SD4 head.

This year I found some knockoff DCOE pattern throttle bodies, I bought some in 48mm, which should be correct diameter for the port area with a 1 degree taper.

This also means I have to fabricate an intake. I plan to run a 3d printed CF-Nylon manifold.

I did some test fitting and Have an idea on how it may fit for now.

I I

I am still working on the details, especially after receiving the later version of the SD4 guide.

|

|

|

|