|

| High NOx Smog Failure (Defeat or Bust) (Page 2/9) |

|

Patrick

|

MAR 06, 08:34 PM

|

|

| quote | Originally posted by Kitskaboodle:

Recently changed caliper? I can’t begin to tell you how many times I had brake fluid leaks at the banjo fitting on the caliper. If that is where the leak is, I can almost guarantee you it’s the copper / aluminum crush washers. (copper is better in my opinion) Anyways, always use NEW ones and make sure they are the proper size and diameter. Ones that fit snugly around the banjo bolt are your best bet.

|

|

New copper washers are not necessary!

| quote | Originally posted by Marvin McInnis:

Yes, copper crush washers can be reused, but they must be annealed first. New copper crush washers should already be in the annealed condition, so you normally should be able to use them right out of the box. (Copper will slowly age-harden at room temperature, though. Those copper crush washers you bought 10 years ago, even though "new," may need to be annealed before use.) When you install them the crushing process work-hardens the copper, so they become much less flexible and may not seal if you try to reuse them "as is." Heating the copper washers to annealing temperature (~1100 degrees F ... a simple propane torch will do) and cooling them back to room temperature will restore their ductility and allow them to be reused once or twice.

Soft aluminum crush washers work-harden when used, too, but they can't reliably be annealed using simple workshop tools and techniques. Just throw them away and buy new ones. I assume that the use of aluminum crush washers is becoming more common due to the increasing price of copper.

|

|

|

|

|

sanderson231

|

MAR 06, 09:02 PM

|

|

| quote | Originally posted by Patrick:

New copper washers are not necessary!

[QUOTE]Originally posted by Marvin McInnis:

Yes, copper crush washers can be reused, but they must be annealed first. New copper crush washers should already be in the annealed condition, so you normally should be able to use them right out of the box. (Copper will slowly age-harden at room temperature, though. Those copper crush washers you bought 10 years ago, even though "new," may need to be annealed before use.) When you install them the crushing process work-hardens the copper, so they become much less flexible and may not seal if you try to reuse them "as is." Heating the copper washers to annealing temperature (~1100 degrees F ... a simple propane torch will do) and cooling them back to room temperature will restore their ductility and allow them to be reused once or twice.

Soft aluminum crush washers work-harden when used, too, but they can't reliably be annealed using simple workshop tools and techniques. Just throw them away and buy new ones. I assume that the use of aluminum crush washers is becoming more common due to the increasing price of copper.

|

|

[/QUOTE]

New copper washers are dirt cheap. It makes no sense to anneal used washers

------------------

formerly known as sanderson

1984 Quad 4

1886 SE 2.8L

1988 4.9L Cadillac

1988 3800 Supercharged

|

|

|

Patrick

|

MAR 06, 09:26 PM

|

|

| quote | Originally posted by sanderson231:

New copper washers are dirt cheap. It makes no sense to anneal used washers.

|

|

Even if copper washers were free (which they're not), it makes more sense to me to avoid the nuisance of chasing down new parts if I can spend two minutes with a propane torch to totally revitalize the copper washers I already posses.

I haven't done a lot of brake work, but I've never had a caliper banjo bolt leak during the 50 years I've been servicing my own vehicles.[This message has been edited by Patrick (edited 03-06-2023).]

|

|

|

Notorio

|

MAR 11, 02:25 PM

|

|

Update on leak ... I want to fix this so I can put the car back on the floor to finish the EGR etc. troubleshooting.

First Image: This is where the leak is coming from. The banjo and the bleeder are not leaking. The bracket has been removed for this picture.

Second Image: This is how the stack goes together. There is a rubber 'washer' type unit and then the very thin plastic ring and you can see where they go. I guess I'm surprised that the plastic ring is not a leak path at all times. Is this really how this is supposed to be? Meanwhile, I'll tottle down to O'Reilly's and see what they have to replace the somewhat beat-up-looking rubber washer.

|

|

|

sanderson231

|

MAR 11, 04:56 PM

|

|

Looks like Rockauto has a rear caliper rebuild kit for less than $10.

I looked at an exploded picture of the caliper and there is an o-ring seal on the inside that keeps brake liquid from coming out. I'm now thinking that the outside seal inside the lever is to keep water from getting in and causing corrosion of the shaft. The piston needs to be removed to look at the inside o-ring seal.------------------

formerly known as sanderson

1984 Quad 4

1886 SE 2.8L

1988 4.9L Cadillac

1988 3800 Supercharged

|

|

|

Notorio

|

MAR 11, 05:18 PM

|

|

| quote | Originally posted by sanderson231:

Looks like Rockauto has a rear caliper rebuild kit for less than $10.

I looked at an exploded picture of the caliper and there is an o-ring seal on the inside that keeps brake liquid from coming out. I'm now thinking that the outside seal inside the lever is to keep water from getting in and causing corrosion of the shaft. The piston needs to be removed to look at the inside o-ring seal.

|

|

Doh, I just finished replacing that outer rubber washer with a viton o-ring that is somewhat thicker. If it continues to leak I'll contact calipersonline and perhaps they will send me the inside seal, since the calipers have <100 miles on them. In the meantime I can move the car again and get back to the High NOx issue

|

|

|

Notorio

|

MAR 11, 06:49 PM

|

|

Kit, I think I'm onto something. Here is the EGR data as a result of (trying to) follow the confusing Field Service Manual's flowchart. It boils down to:

1) does the EGR Solenoid open around 1800 rpm

2) does the vacuum applied to the EGR Valve exceed 2" of Hg (and is it less than 10".)

The vacuum gauge that I have is VERY hard to read below perhaps 4". I did multiple measurements and MOSTLY have convinced myself that the EGR Solenoid DOES work, that the lines from the Throttle Body to the Solenoid to the Valve DO NOT leak, however, the vacuum the EGR sees is marginally LESS than what will open the valve using a manual pump. i.e. the 2" reading that I think I see at the Valve is less than the 3" the Valve needs to open. If I apply the alleged 2" with a manual pump the valve stays closed. At about 3" the valve opens the the IDLE starts to stumble.

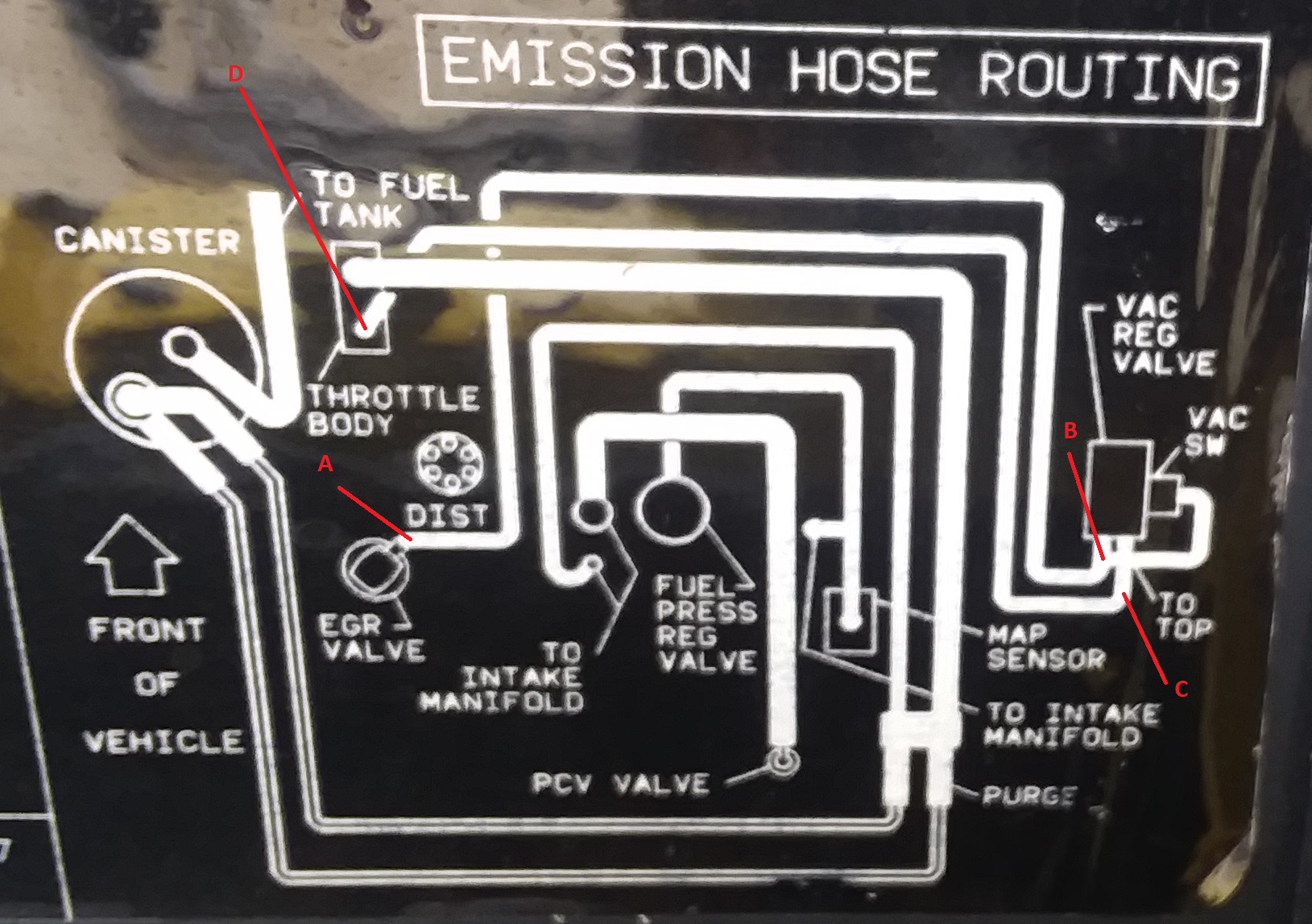

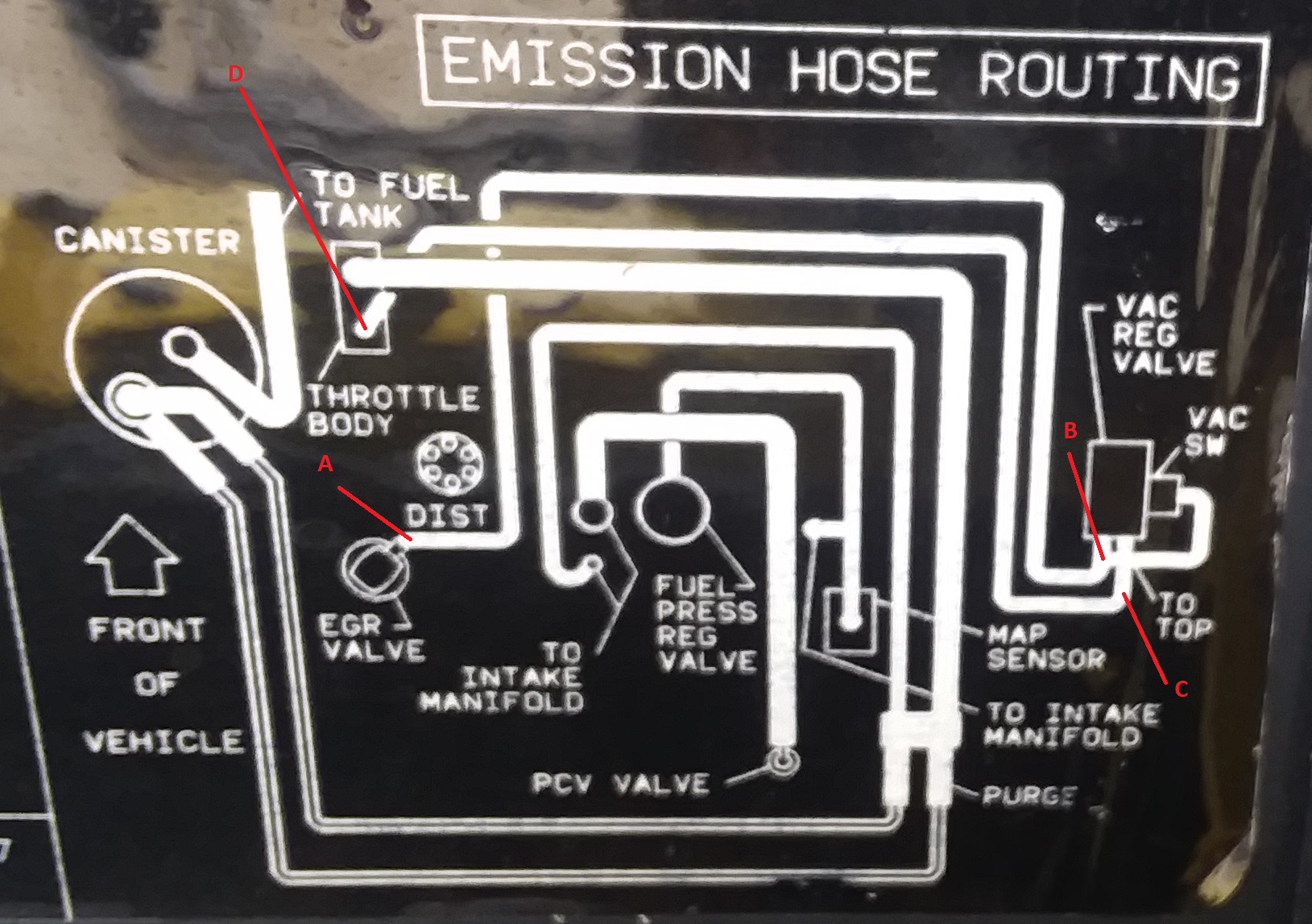

Referring to the diagram below, I started my measurements at A but worked myself back to D to test for leaks in the vacuum circuit. The reading is the SAME at A, B, C, and D. If there is a drop-off, the gauge is too insensitive to pick it up. Anyway, I think the question is now HOW do I increase the ported vacuum from the Throttle Body to something more like 4-5"??

p.s. I MIGHT just fashion myself a Water Manometer so I can see very clearly if the System Vacuum really is sufficient to open the EGR Valve.

[This message has been edited by Notorio (edited 03-12-2023).]

|

|

|

sanderson231

|

MAR 11, 08:09 PM

|

|

| quote | Originally posted by Notorio:

p.s. I MIGHT just fashion myself a Water Manometer so I can see very clearly if the System Vacuum really is sufficient to open the EGR Valve.

|

|

FYI, 1" of Hg is equivalent to 13.6" of water

|

|

|

Notorio

|

MAR 11, 11:58 PM

|

|

| quote | Originally posted by sanderson231:

FYI, 1" of Hg is equivalent to 13.6" of water |

|

Right. I've got some clear Tygon tubing I use in wine making that I figured I could easily rig up 6' or so ...

|

|

|

sanderson231

|

MAR 12, 03:59 PM

|

|

Some other thoughts:

1) partially clogged EGR passage in intake manifold creating flow restriction

2) cracked EGR tube allowing air to enter with EGR gases causing lean condtion

2) small leak in diaphragm of ECR valve causing reduced opening at a given vacuum

3) wrong EGR valve there are three types; negative back pressure, positive back pressure and port. The numbers on the valve should be formatted like:

CBT 17083821

34121

There should be no N or P after 34121 (date built). This indicates the correct port type valve

17083821 is the part number

Since you do not have a code 32 the EGR is likely seeing at least 2" of vacuum with EGR commanded on.

EGR is commanded on at 1200 rpm and MAP's less than 60 kPa. However the duty cycle is not large 11.7 % to 19.5% depended in MAP so normal vaccum to EGR valve may not be that high.

------------------

formerly known as sanderson

1984 Quad 4

1886 SE 2.8L

1988 4.9L Cadillac

1988 3800 Supercharged

|

|

|

|