|

| OEM V6 Distributor: Any Options to Reduce Corrosion / Oxidization on the POLE PIECE? (Page 2/6) |

|

Patrick

|

MAY 08, 02:06 PM

|

|

| quote | Originally posted by Vintage-Nut:

I'll look at the two stock screened vents on the base and think about widening them...

|

|

Unless you use your vehicle commercially, like as a taxi cab for example, and it's running eight hours a day every day... I don't know why you're this concerned about ozone inside the distributor cap corroding anything.

You saw how bad my distributor was. I cleaned it up, installed a new pickup coil, applied new heat sink compound (and a heat sink)... and I haven't been inside that distributor again in the last 15 years. I should add that I transferred that distributor from my '86 GT to my '88 Formula when the Formula became my daily driver (as well as my autocross vehicle). The engine runs great with my ratty looking, ozone infested, rusted out distributor.  [This message has been edited by Patrick (edited 05-08-2023).]

|

|

|

sanderson231

|

MAY 08, 05:14 PM

|

|

|

There is a product called Evap-O-Rust that is incredible for rust removal. Remove the loose rust, soak it overnight and you will have bare metal in the morning. Fantastic on rusty tools as well. It is a chelating solution and not an acid solution. It solubilizes iron oxide and does not touch the base metal. ------------------

formerly known as sanderson

1984 Quad 4

1886 SE 2.8L

1988 4.9L Cadillac

1988 3800 Supercharged

|

|

|

pmbrunelle

|

MAY 08, 07:20 PM

|

|

I think that centrifugal force might throw any grease off the rotating parts, leaving them bare. Probably some sort of plating solution is in order.

Also, I think the new style star type distributor (versus the bent-finger type) isn't too rust-prone. I don't remember seeing any excessive corrosion on my new style distributor, but then again, it hasn't seen decades of service.[This message has been edited by pmbrunelle (edited 05-08-2023).]

|

|

|

theogre

|

MAY 09, 12:07 AM

|

|

| quote | Originally posted by pmbrunelle:

I think that centrifugal force might throw any grease off the rotating parts, leaving them bare. Probably some sort of plating solution is in order.

Also, I think the new style star type distributor (versus the bent-finger type) isn't too rust-prone. I don't remember seeing any excessive corrosion on my new style distributor, but then again, it hasn't seen decades of service. |

|

Dist RPM is 1/2 of Engine RPM so not as "bad" as many think.

Another reason to try PBG. (Green label)

Very thin coat may still spun off but only a film should help the rust problem.

Sil oil/grease would spin off easier but may still work.

Important Note: Magnet parts don't need bright metal to work but if parts are rotted thin then metal and pickup can't see the magnet pules.

So When cleaning, don't clean all rust. just lose big stuff on magnet parts and "grease" them

Or rust converter, Forget name/type right now, greenish clear liquid. Not others that are thick liquid like naval jelly etc.

If have dist out and took apart, could nickle plate them.

or maybe Cold Blueing then oil etc.

Either shouldn't cause major clearance problems. only parts are press onto another might get very tight.

|

|

|

Vintage-Nut

|

MAY 09, 12:30 PM

|

|

| quote | by Patrick

The engine runs great with my ratty looking, ozone infested, rusted out distributor. |

|

Back in high school, we had a saying “Show or Go” but I really enjoy both!

| quote | by sanderson231

There is a product called Evap-O-Rust that is incredible for rust removal. |

|

Thanks for the tip!

| quote | by theogre

Important Note: Magnet parts don't need bright metal to work but if parts are rotted thin then metal and pickup can't see the magnet pules.

So When cleaning, don't clean all rust. just lose big stuff on magnet parts and "grease" them. |

|

I purchased a GM 10497450 main shaft so hopefully a film of green label PBG will protect or diminish the decay than ‘bare metal’.

Thanks again for the help,

VN

|

|

|

Patrick

|

MAY 09, 03:10 PM

|

|

| quote | Originally posted by Vintage-Nut:

Back in high school, we had a saying “Show or Go” but I really enjoy both!

|

|

I'm more interested in "Go", but when I wash my Formula, it doesn't "Show" too bad... and nobody but nobody can see the surface corrosion inside my distributor that affects nothing.

|

|

|

Vintage-Nut

|

JUN 01, 12:19 AM

|

|

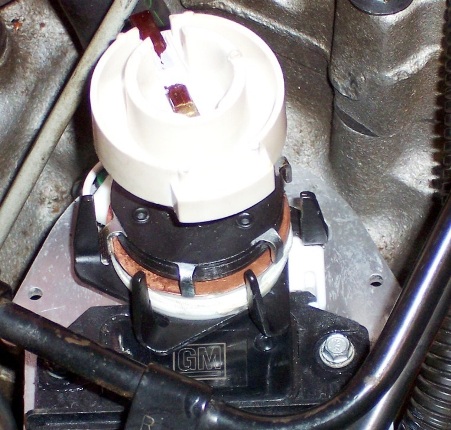

I'm closing the loop on this thread which asked "if there is a ‘better way’ to protect or diminish the decay" of the pole piece and the rotating magnet piece.

The results was "properly coat/protect the parts" so I painted them. (Except the tight clearance area of the magnet projections and the pole piece)

Given that the distributor was apart; I added more venting area plus a small heat sink for the ICM as many members posted ‘heat’ issues.

I hope my “Show AND Go” efforts will diminish the corrosion; the 'real test' will be time at the next distributor cap/rotor change....

VN

|

|

|

theogre

|

JUN 01, 11:56 AM

|

|

Ozone isn't only problem here...

1. After shutdown, the engine and the rest heat cycles to cool/cold drawing in air and Often means Moisture Too. Then water can condense on everything inside and rust metal parts.

You may never see "wet" parts but still happens. Thin coat of oil/grease, or paint, will resist this problem too.

2. Other things including some cars has/had vented caps or somewhere else.

Why?

Ozone and Ionize Air and Dirt are a problem just to run the engine because functionally tries to short out the ⚡ high volt side causing ignition miss or worse.

May not easily see a "vent" but most distributors are not air sealed but try only to keep out "water" in them.

V6 and other w/ dist on top of engine shouldn't have problems w/ vent(s) like above.

But If try that on Duke and many others... Likely will have problems driving in bad weather because how mounted and more exposed to road water. Worse is Duke w/ stick trans as trans don't "shield" the Dist letting more water hitting it.

Paint works but has a bad habit of lifting off if damage or skipped the tiniest area as that spot will rust and rust grows under.

|

|

|

reinhart

|

JUN 01, 08:52 PM

|

|

| quote | Originally posted by Vintage-Nut:

Given that the distributor was apart; I added more venting area plus a small heat sink for the ICM as many members posted ‘heat’ issues.

I hope my “Show AND Go” efforts will diminish the corrosion; the 'real test' will be time at the next distributor cap/rotor change....

VN |

|

Totally useless if you understand basic thermodynamics. What temperature is the distributor? Pretty much the same temperature as the metal of the engine block where it's mounted. If your little heat sink were to work, then you'd be effectively cooling the entire engine with that 1 sq inch heatsink. Is that what you believe you're doing? And do you really believe that little heatsink is going to offset the heat soak from that big 300 pound block of iron it is attached to? Also what temperature is the pocket of air next to the distributor with the decklid closed that that miniscule amount of heat is supposedly being displaced to? Pretty much the same as the temperature of the engine.

The reason a laptop computer has a heat sink for the chip is because the chip is hotter than the rest of the computer and hotter than the ambient air. That distributes the heat to the rest of the computer and its surrounding air.

The Fiero ICM is generating heat and can get hotter than the rest of the distributor if it weren't mounted to the distributor, but when solidly attached, the grease distributes the extra heat to the distributor body and to the engine itself. However, the distributor isn't going to get cooler than the engine it's mounted to.

Let's remember GM tried using an air blower on the distributor (and the alternator) and removed it in 88 because it wasn't doing anything. Notice they didn't even bother trying to add a heatsink. Surely that would have been cheaper than the blower motor, piping etc which they did try.

|

|

|

pmbrunelle

|

JUN 01, 09:24 PM

|

|

| quote | Originally posted by reinhart:

Totally useless if you understand basic thermodynamics. What temperature is the distributor? Pretty much the same temperature as the metal of the engine block where it's mounted. If your little heat sink were to work, then you'd be effectively cooling the entire engine with that 1 sq inch heatsink. Is that what you believe you're doing? And do you really believe that little heatsink is going to offset the heat soak from that big 300 pound block of iron it is attached to? Also what temperature is the pocket of air next to the distributor with the decklid closed that that miniscule amount of heat is supposedly being displaced to? Pretty much the same as the temperature of the engine.

The reason a laptop computer has a heat sink for the chip is because the chip is hotter than the rest of the computer and hotter than the ambient air. That distributes the heat to the rest of the computer and its surrounding air.

The Fiero ICM is generating heat and can get hotter than the rest of the distributor if it weren't mounted to the distributor, but when solidly attached, the grease distributes the extra heat to the distributor body and to the engine itself. However, the distributor isn't going to get cooler than the engine it's mounted to.

Let's remember GM tried using an air blower on the distributor (and the alternator) and removed it in 88 because it wasn't doing anything. Notice they didn't even bother trying to add a heatsink. Surely that would have been cheaper than the blower motor, piping etc which they did try. |

|

If you understand anything about thermodynamics, you might accept the possibility of a thermal gradient existing between the ICM base and the engine block.

|

|

|

|