|

| Upgrade 84-86 2.5s w/ newer 87 belt system, possible? (Page 2/3) |

|

82-T/A [At Work]

|

OCT 12, 11:04 PM

|

|

Ok, so, I never updated this thread, and figured I would do it now, while also asking a question (next post).

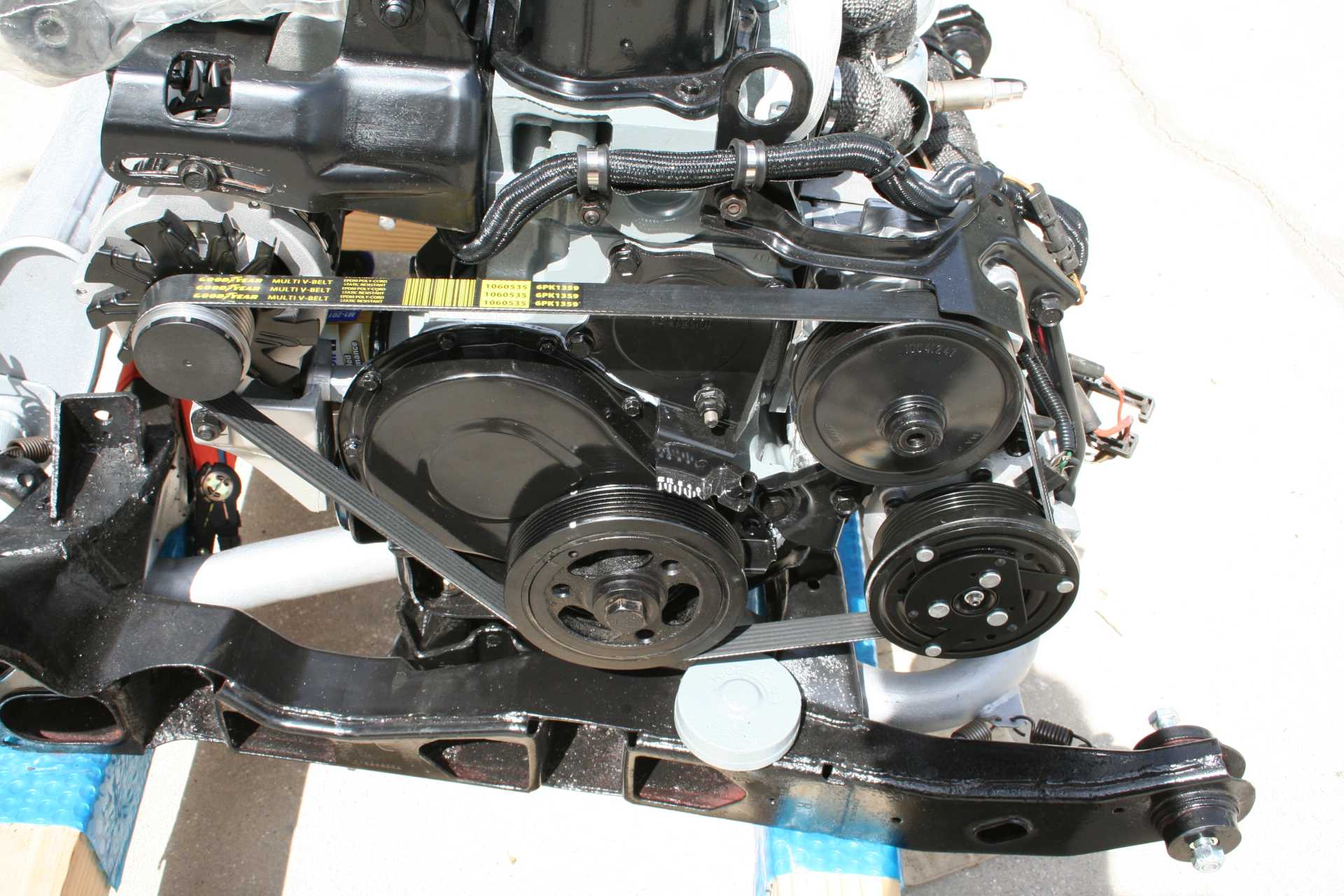

I was able to upgrade to pretty much everything on the 87-88 engine... this is what I did (I'll update this later with more detail when I have time):

- Kept the upper and lower alternator bracket for the 1985-1986. That's because I cannot install the 87-88 belt tensioner on an 84-86 block. So... the alternator becomes the belt tensioner.

- I used the waterpump pulley from a 1987-1988 (6-groove serpentine pulley)

- I swapped out the pulley on the alternator with a 6-groove serpentine pulley from an 87-88. (I actually upgraded to a CS130 and installed a decoupler pulley)

- I replaced the crank pulley and hub with a brand new General Motors harmonic balancer for a 1989-1991 Iron Duke, which I was able to find online. (but you can just swap over the 87-88 6-groove pulley and hub.

- I used 1987-1988 A/C compressor brackets, and installed an 86+ L4 A/C compressor with a 6-groove serpentine pulley.

Although it looks bad, it's actually the same surface area as the previous V-belt system had. I'm looking for a solution to install somee kind of idler pulley to give me a little bit more surface area on the crank.

|

|

|

82-T/A [At Work]

|

OCT 12, 11:06 PM

|

|

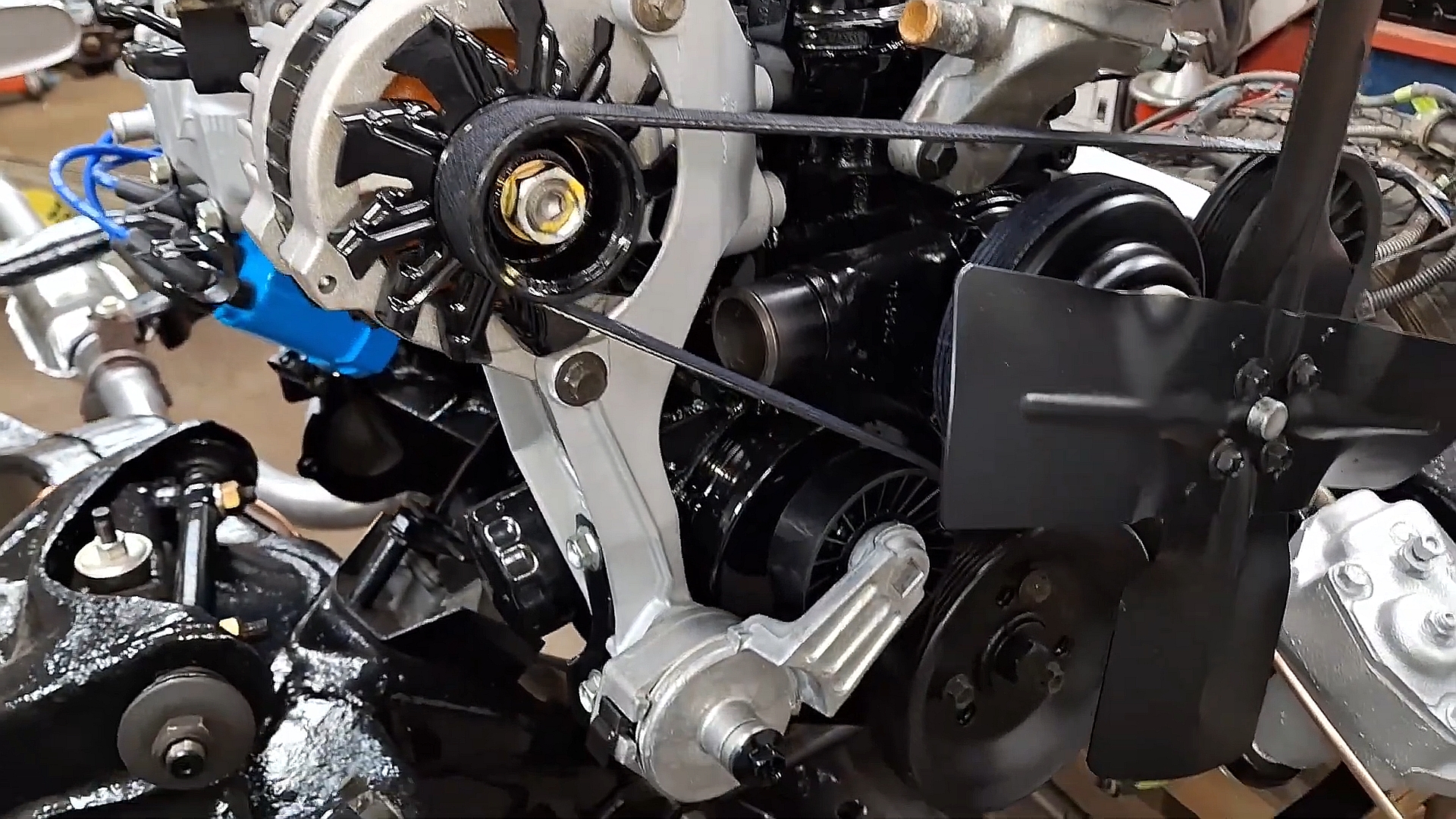

So, quick question... I was looking on some website about Iron Dukes, and found this image of a 1991 Iron Duke from a Chevy S-10 Pickup.

Right there in the lower left-corner of the engine block, there is a belt tensioner. I'm wondering how this installs, and what the brackets look like... anyone have any idea?

|

|

|

Patrick

|

OCT 13, 03:05 AM

|

|

| quote | Originally posted by 82-T/A [At Work]:

Although it looks bad, it's actually the same surface area as the previous V-belt system had. I'm looking for a solution to install somee kind of idler pulley to give me a little bit more surface area on the crank.

|

|

I think you're absolutely going to need an idler pulley or tensioner mounted on there. I suspect with any kind of a load on that belt (ie A/C turned on and/or heavy electrical draw), especially if/when wet, that the belt will slip badly.[This message has been edited by Patrick (edited 10-13-2024).]

|

|

|

Patrick

|

OCT 13, 03:25 AM

|

|

| quote | Originally posted by 82-T/A [At Work]:

So, quick question... I was looking on some website about Iron Dukes, and found this image of a 1991 Iron Duke from a Chevy S-10 Pickup.

Right there in the lower left-corner of the engine block, there is a belt tensioner. I'm wondering how this installs, and what the brackets look like... anyone have any idea?

|

|

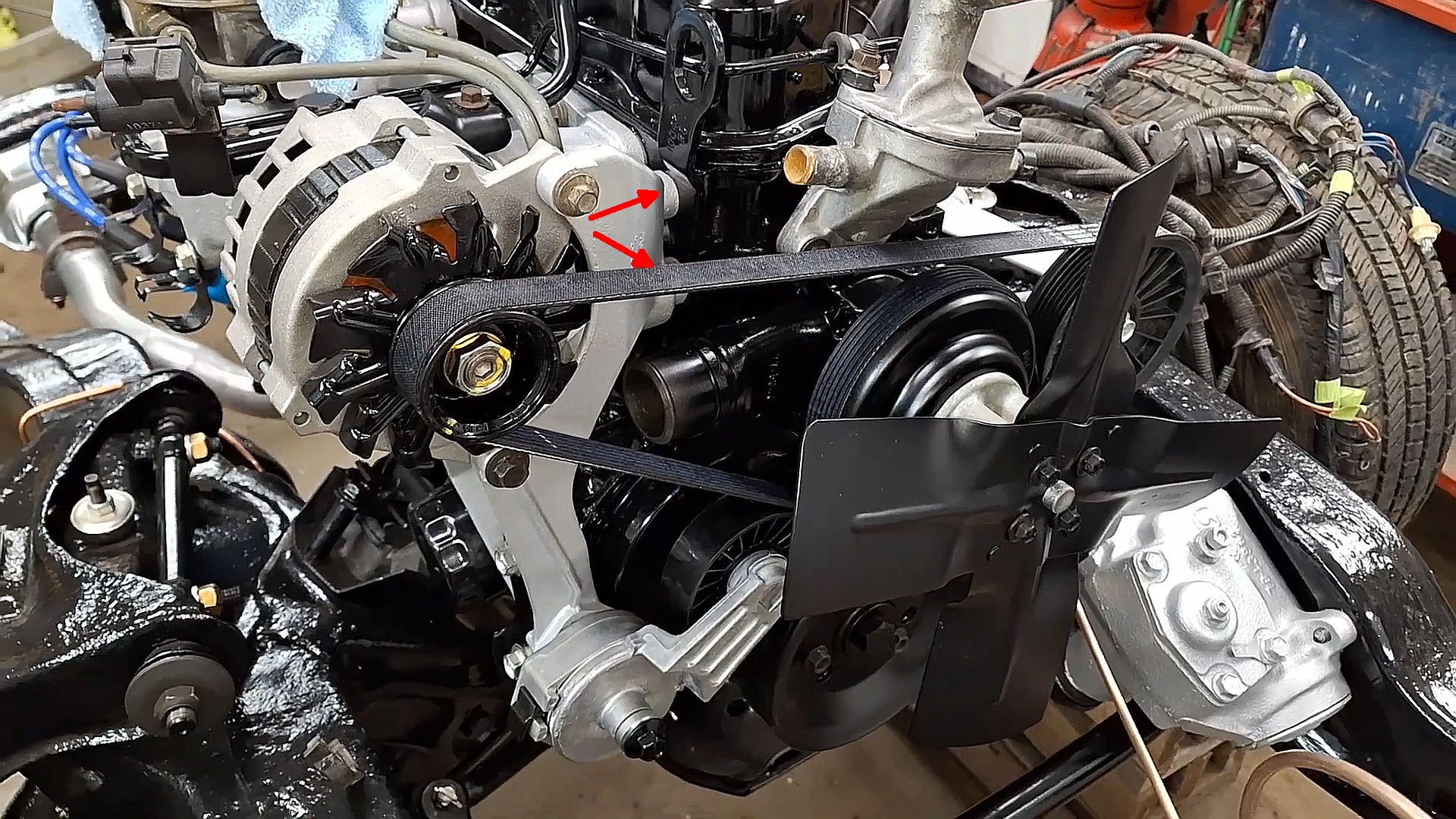

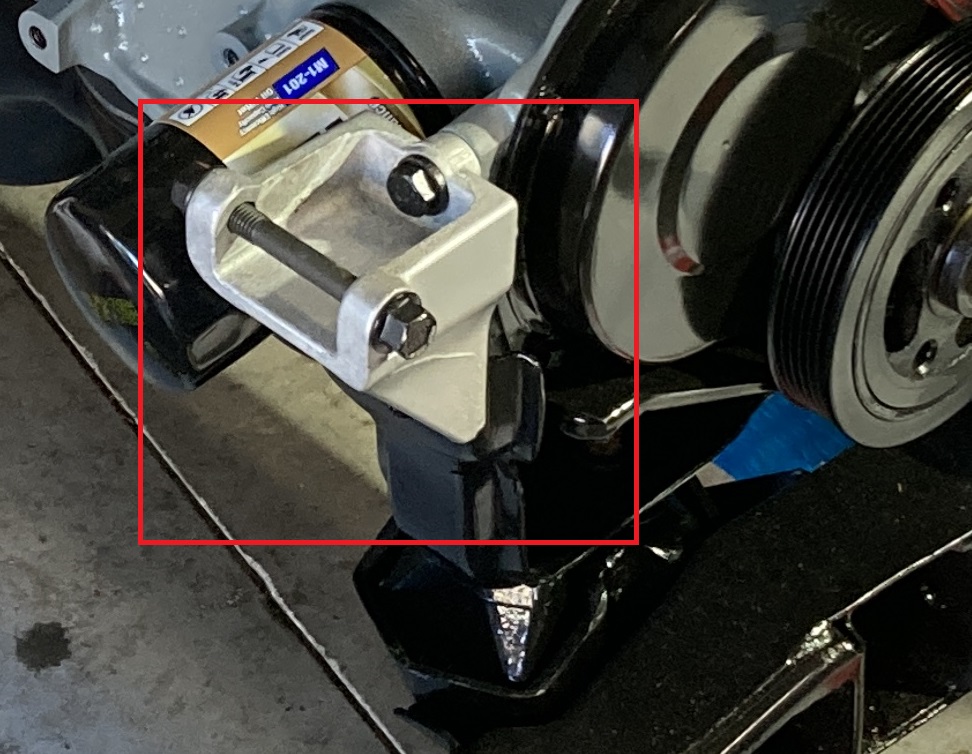

How's this?

From Here.

|

|

|

82-T/A [At Work]

|

OCT 13, 09:52 AM

|

|

| quote | Originally posted by Patrick:

How's this?

From Here. |

|

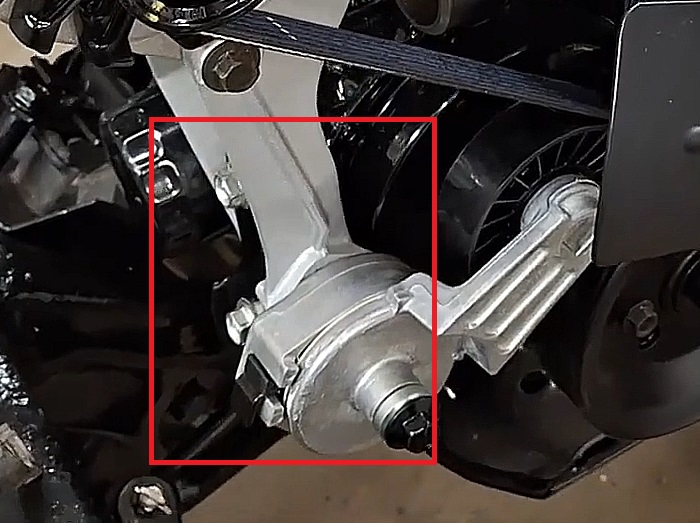

Oh wow, that's fantastic! Thanks Patrick! That thing looks like it can easily be cut (at the bottom) and installed in place of the lower alternator bracket!!!

Looking more at it, I would need to modify this bracket, and the tensioner itself can't be used as a tensioner (so to speak), and that the alternator still needs to be used as the thing that "tensions" the belt, but I have a spare stock bracket, and I'm wondering if I can't simply just drill a hole in the spare lower bracket I have, and install a tensioner on there?

I'm going to have to try to find one of these guys... but It may be as simple as drilling a hole in one of my spare brackets, and then a smaller hole for the tensioner mount, and then using it all the same. The rest of it doesn't seem to add any strength to the tensioner part... just to hold the alternator.[This message has been edited by 82-T/A [At Work] (edited 10-13-2024).]

|

|

|

Patrick

|

OCT 13, 02:53 PM

|

|

| quote | Originally posted by 82-T/A [At Work]:

I would need to modify this bracket, and the tensioner itself can't be used as a tensioner (so to speak), and that the alternator still needs to be used as the thing that "tensions" the belt...

|

|

If that bracket seen in the image could be adapted to fit on your duke, why couldn't the tensioner be used as it was designed to be used for?  What am I missing? What am I missing?

|

|

|

82-T/A [At Work]

|

OCT 13, 06:15 PM

|

|

| quote | Originally posted by Patrick:

If that bracket seen in the image could be adapted to fit on your duke, why couldn't the tensioner be used as it was designed to be used for?  What am I missing? What am I missing?

|

|

Difference is, in the S10, the alternator sits really high up on the engine, since it's in a rear wheel drive configuration. In the Fiero, it sits down low. So I'd have to cut the S10 bracket to lower the alternator.

But I don't think that's totally what you're asking. I suppose I COULD use the dog-bone bracket from the 88 engine that I had (if I can still find it), and then use the bracket. I think it was quite literally just a steel rod with a hole on either side. I can't remember. It would require me to have to get another new CS130 alternator though. Not a huge deal though, because I can use this one for my 87. Something to think about.

|

|

|

Patrick

|

OCT 13, 07:48 PM

|

|

| quote | Originally posted by 82-T/A [At Work]:

Difference is, in the S10, the alternator sits really high up on the engine, since it's in a rear wheel drive configuration. In the Fiero, it sits down low. So I'd have to cut the S10 bracket to lower the alternator.

|

|

Cutting the S10 bracket was what I was actually thinking of, as all you really need is the lower part to mount the tensioner to... however, it appears that the lower part of the bracket is basically just hanging there (it's hard to tell), and that the upper part of the bracket is required in order to bolt to the side of the head (as indicated with red arrows) for support. Hmmm...

|

|

|

82-T/A [At Work]

|

OCT 13, 08:04 PM

|

|

| quote | Originally posted by Patrick:

Cutting the S10 bracket was what I was actually thinking of, as all you really need is the lower part to mount the tensioner to... however, it appears that the lower part of the bracket is basically just hanging there (it's hard to tell), and that the upper part of the bracket is required in order to bolt to the side of the head (as indicated with red arrows) for support. Hmmm...

|

|

The lower part of the bracket attaches to the two bolts on the block (look at my picture), where the Fiero's lower alternator bracket attaches to. Those two bolt holes are still there.

I basically just need to find a way to combine this...

and this...

They both use the same bolt holes in the bottom. My thought was to take both of them, bolt them together (back to back) when / if I can find one, and then put it on a band saw and cut them perpendicularly. Now... I'd have the top part of the Fiero's lower alternator bracket, and the bottom part of the Chevy S-10 alternator and belt tensioner bracket, and then take them to someone who knows how to weld aluminum, and ask them to weld those two halves together to get me what is basically a lower Fiero alternator bracket with a belt tensioner attached to the bottom of it.

|

|

|

Patrick

|

OCT 13, 08:09 PM

|

|

You posted that while I was hunting for the following image. I was wondering where the bottom two bolts went, but your image above answers that. This is the kind of stuff I enjoy figuring out, but it would be so much easier if it was all in front of me.

|

|

|

|