|

| 18x9.5 wheels don't fit, what did I do wrong? Please help (Page 3/3) |

|

pmbrunelle

|

JAN 28, 12:29 PM

|

|

| quote | Originally posted by fieroguru:

You don't have to run the sleeve all the way down to the bolt flange. Cut the spring perch above the weld bead and mount the sleeve on top of it.

|

|

If it's not a trade secret, what PN of coilover sleeve do you use that works in that position?

|

|

|

fieroguru

|

JAN 28, 07:27 PM

|

|

| quote | Originally posted by pmbrunelle:

If it's not a trade secret, what PN of coilover sleeve do you use that works in that position? |

|

You need a sleeve that is 2" in diameter and 4 3/4" long.

I sell these are part of my level 1 kit which includes the sleeves, strut hat, bump stop and all stainless steel hardware.

|

|

|

pmbrunelle

|

JAN 28, 08:36 PM

|

|

For the length I'm not super-concerned. I have found that a normal wood-cutting blade (carbide-tipped) on a chop saw works for cutting aluminium like this.

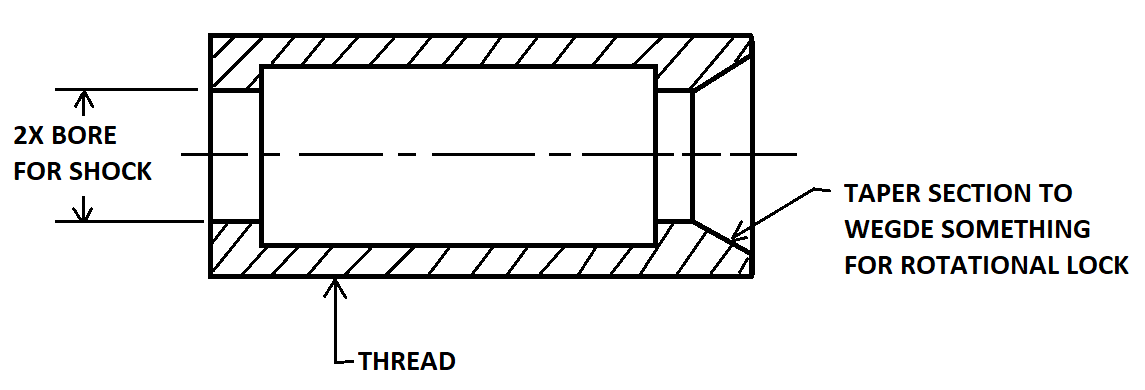

One thing I noticed with Allstar sleeve is that it centers on the shock using two bores:

This makes it difficult to trim the sleeve to an arbitrary length.

Have you noticed if most coilover sleeves have a diameter increase in the middle, or if the bore is usually constant?

I was looking at these since they are in-stock on Summit. The QA1 60-series shock for which this sleeve is made is a 2" OD shock.

https://www.summitracing.com/parts/qa1-ck6007

I like the jam nut concept (good idea) which I saw on your coilovers. I am annoyed with set screw coilover nuts, as they damage the threaded sleeve when tightened.

I am wondering what's the probability of these sleeves having a constant bore, or if there's a larger center section which may make cutting to length problematic. From the picture, I don't see the step, but that's more of a stock photo.

What's also weird is that the photo doesn't show a tapered wedge section, though I might have to buy a pair to get more info. Last time I asked QA1 for information via their online fill-form they never got back to me.

|

|

|

fieroguru

|

JAN 29, 09:46 AM

|

|

My sleeves are a constant diameter for the bottom 80% of the length.

Depending on how custom the set of coilovers are, I sometimes bore the ID and reduce the OD of the weld bead to allow the sleeve to hang down below the weld sleeve but still not need to rest on the lower flange.

When running the sleeve on the weld bead, with 275 lb/in and 10" springs about 1" lower is when you run out of adjustment. So when higher rates or lower stance is required, the sleeve needs to be slighly below the spring perch.

|

|

|

pmbrunelle

|

JAN 29, 09:59 PM

|

|

| quote | Originally posted by fieroguru:

Depending on how custom the set of coilovers are, I sometimes bore the ID and reduce the OD of the weld bead to allow the sleeve to hang down below the weld sleeve but still not need to rest on the lower flange. |

|

That sounds like an 88-only trick.

On the 84-87, the strut is more vertical, so if you're running the threaded sleeve on the weld bead so that the wheel rim clears the strut body, you don't have much chance of the tire clearing the spring perch.

|

|

|

fieroguru

|

JAN 30, 09:25 AM

|

|

| quote | Originally posted by pmbrunelle:

That sounds like an 88-only trick.

On the 84-87, the strut is more vertical, so if you're running the threaded sleeve on the weld bead so that the wheel rim clears the strut body, you don't have much chance of the tire clearing the spring perch. |

|

I have done the mod on both. It really comes down to wheel, tire, and offset chosen. Here you can see there is plenty of room for the bottom of the sleeve to hang down as long as the tire doesn't bulge past the edge of the rim. The adjuster rings can also be thrown in the lathe to have most of the slot depth removed to make their OD even smaller. I offer a lot of custom options for my customers specific application.

|

|

|

Will

|

FEB 01, 10:06 AM

|

|

| quote | Originally posted by huracan2015:

So I did hours of research, got all the parts needed to build coilovers, and ordered some 18x9.5 45mm wheels for the rear. They don't fit. The rim itself measides 10.5 wide which is the extra inch I need for clearance. Those of you with 9.5s, how did you make them fit? My car is an '87 by the way |

|

| quote | Originally posted by huracan2015:

Here is the clearance. It "fits" but once I put on my coilovers, the sleeve will take up all of that gap and then some. I can add a small spacer, maybe 10mm to be safe, but the wheels already stick out pretty much as far as I'm willing to go

|

|

Did the "real numbers" ever get posted here?

C5 Corvette rear wheels: 18x9.5 w/ 61mm offset. Use a 25mm spacer to get down to 36mm offset: https://www.fiero.nl/forum/.../000121-21.html#p813

IE, if you use 18x9.5-45 and a 10mm spacer to bring the offset down to 35, they should fit fine.

Use a longer lug stud with any spacer.

|

|

|

|