|

| 2.8L vs. 4.9L (Page 3/3) |

|

Will

|

NOV 10, 11:23 AM

|

|

|

I don't get why people are afraid of wiring. Like you said, each wire only has two ends.

|

|

|

sourmash

|

NOV 10, 12:04 PM

|

|

|

Fear of not finishing it? Reluctance to studying to the point of understanding?

|

|

|

Mickey_Moose

|

NOV 10, 02:49 PM

|

|

| quote | Originally posted by sourmash:

Fear of not finishing it? Reluctance to studying to the point of understanding? |

|

It doesn't take an excessive amount of time, it takes far more time to pull the engine out.

Understanding - all you have to do it connect point A to point B, no studying needed. For example: if the pinout shows that ECM pin 1 goes to speed sensor, then just connect it to the speed sensor.

|

|

|

pmbrunelle

|

NOV 11, 12:09 AM

|

|

Wiring is a pretty long process. As a semi-first-timer, it took me about five months to modify the engine harness wiring on my V6 Fiero (not a 4.9, but the lessons should apply), working maybe 15-20 hours a week on it. The less you know, the longer it will take, as you have to research things.

Everything seems hard when you don't know... but after taking the time to learn, things become obvious.

*****TYPICAL TASKS TO COMPLETE A WIRING HARNESS JOB***** (more or less my experience with wiring)

Research which harness tape to use (that won't turn into a gummy mess), then order it.

Goto junkyard, pull split loom of varying sizes, wash and let dry.

Order new split loom from somewhere

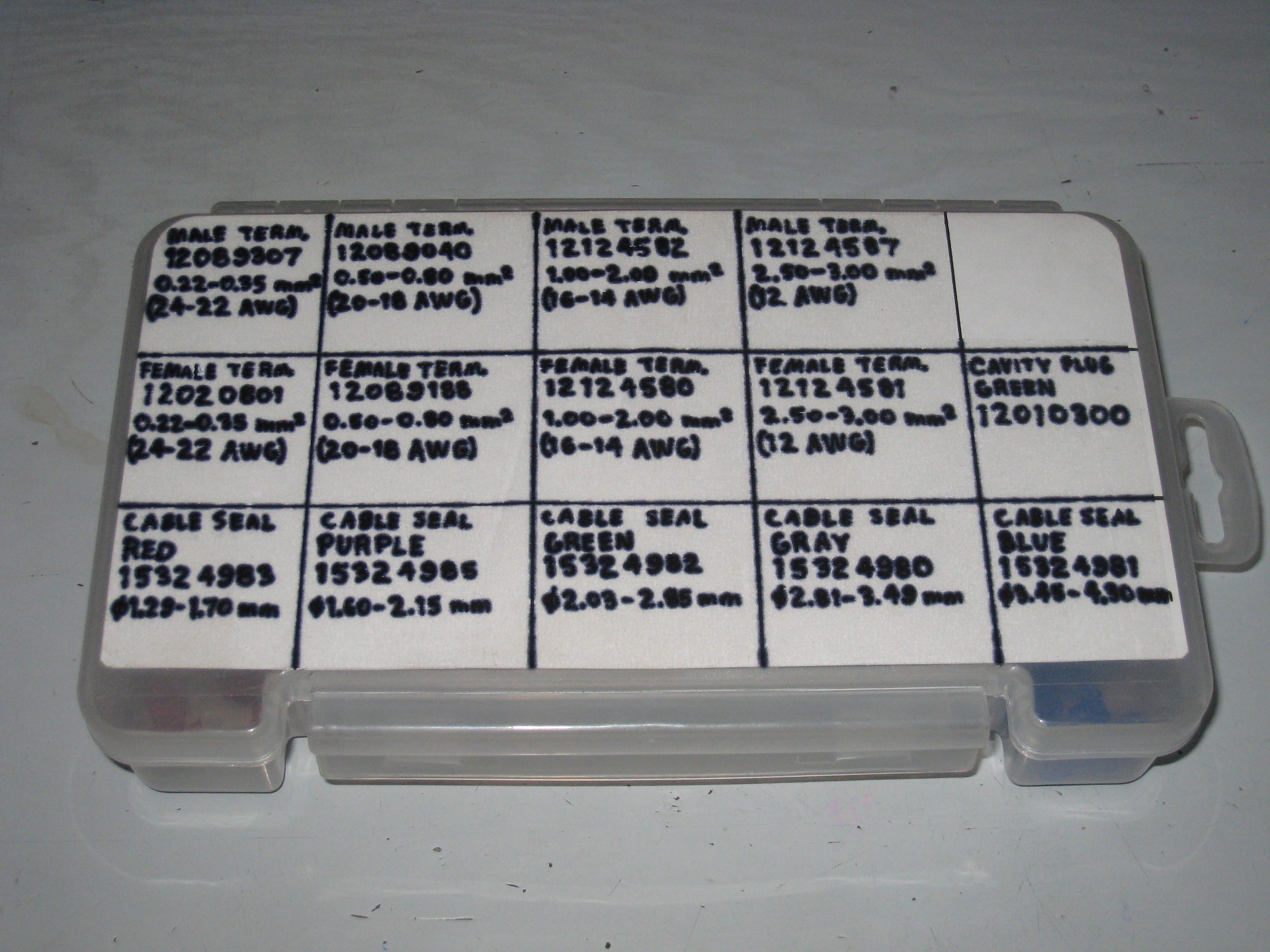

Study the Delphi catalog, understand the relevant part numbers, then build up an inventory of Weather Pack parts

Place some of your selected loom/tape on your daily driver's engine, then drive around for a while to test durability.

Research crimping tools with best cost/productivity ratio for the volume you're doing, then order.

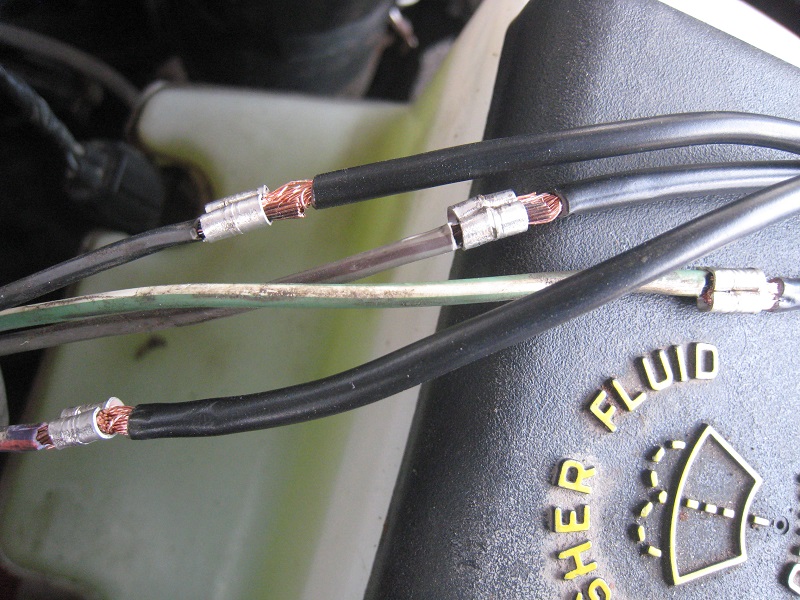

Do practice crimps, then perform pull tests to qualify parts + tooling combination

Again, using the beater daily driver as a test bed, test your splice method (parts+tools+technique) before letting it near the sacred Fiero. Put some time/miles on it...

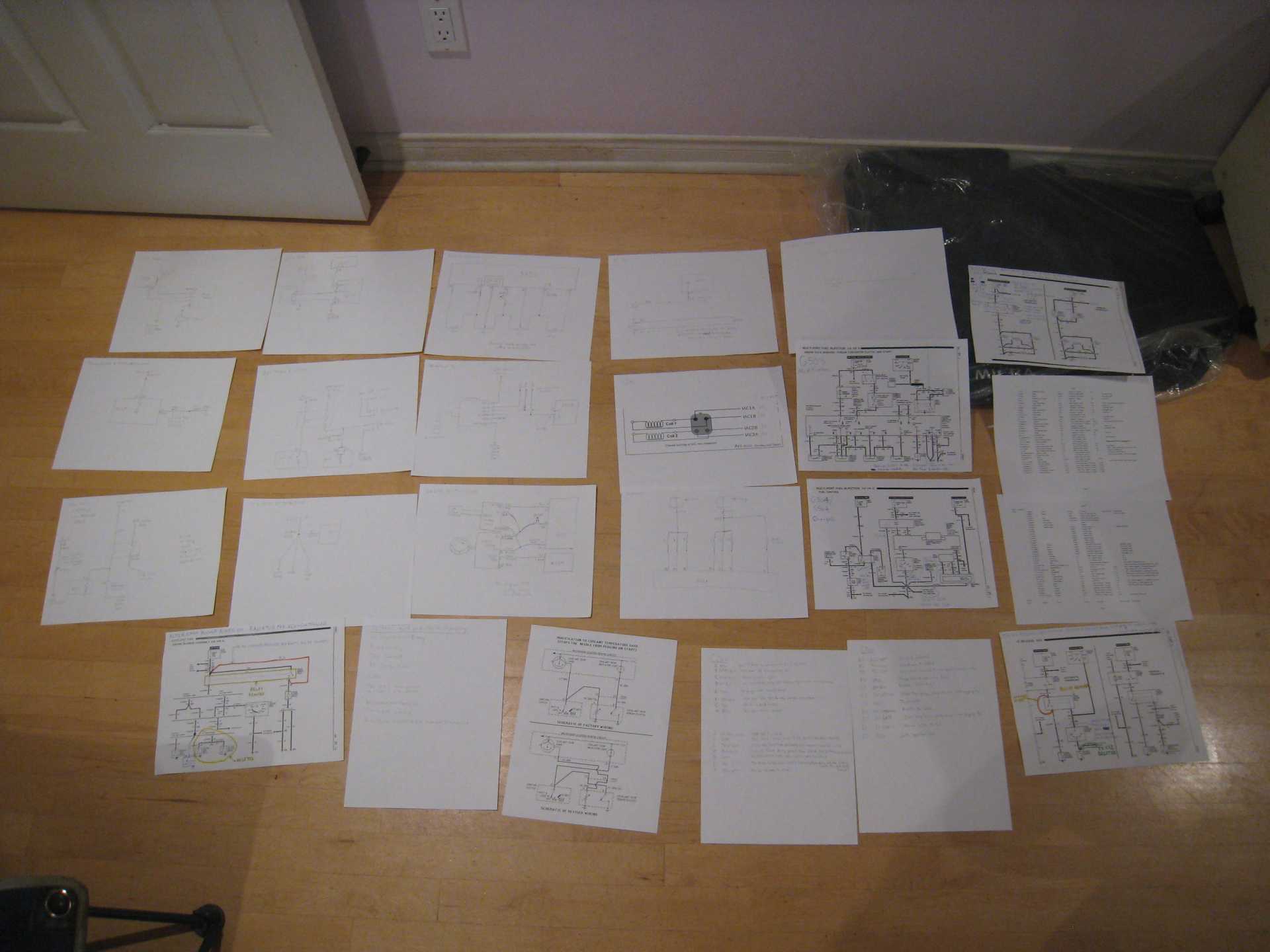

Take the time to draw schematics of everything that's been modified, to facilitate troubleshooting by future you.

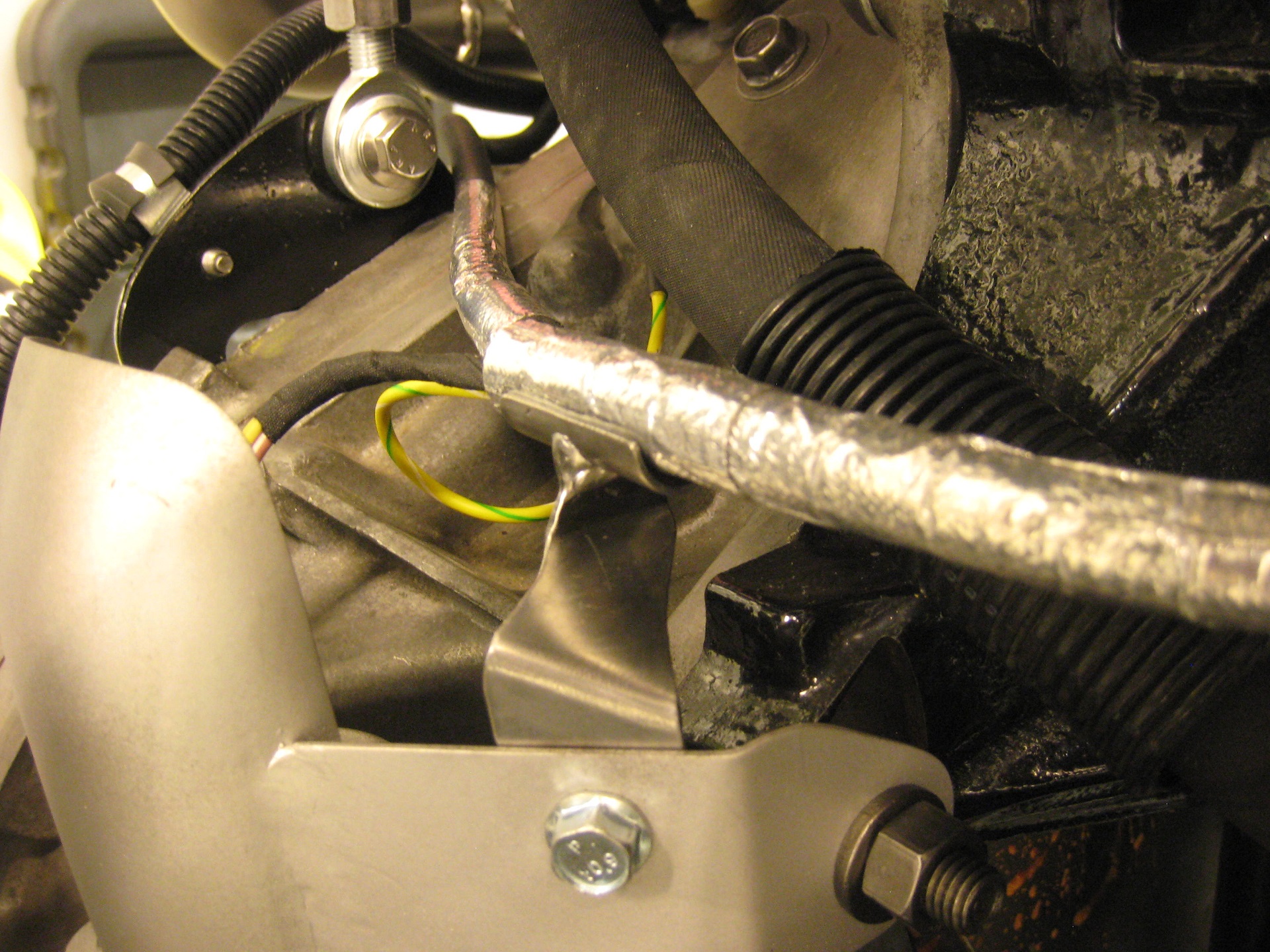

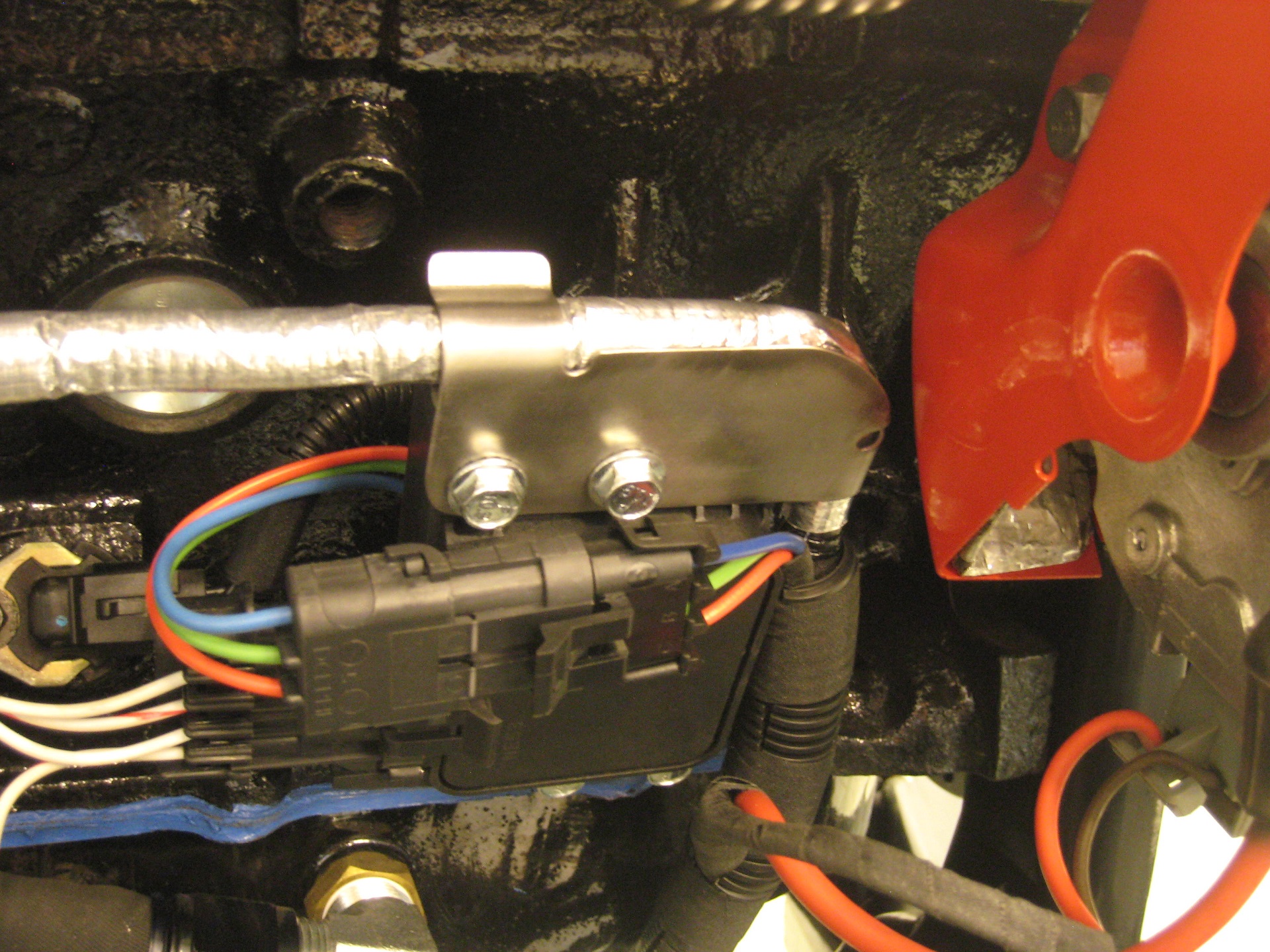

Cut and weld heatshield to protect electrical connectors, sandblast + paint:

Cut and weld various other harness supports, sandblast + paint:

Plan ahead, so you don't have to resandblast + repaint parts that have already been painted.

Function test: test each circuit in the car before taping + looming the harness. If you find a bug, you don't want to have to unwrap everything.

Engine-to-body connections also add a bunch of time to the process; the wire lengths/paths of these connections can only be determined with the powertrain in the body, then you drop the cradle+powertrain to finalize things. My cradle went in/out once or twice for wiring purposes.

It's a plumbing job; you're just channeling electrons to the right places. Instead of tubing and fittings, it's wiring and connectors. Due to the number of wires (well, with fuel injection), it's long and tedious, but you can get there.

MUCH more than a weekend job, if you ask me, but I'm a slow worker.

And I still cut corners not researching everything adequately. I used GPT primary wire in some places... afterwards I learned that PVC insulation is el-cheapo stuff that doesn't belong on a project car, and I should have used GXL (cross-linked polyethylene) instead.

|

|

|

Neils88

|

NOV 11, 11:45 AM

|

|

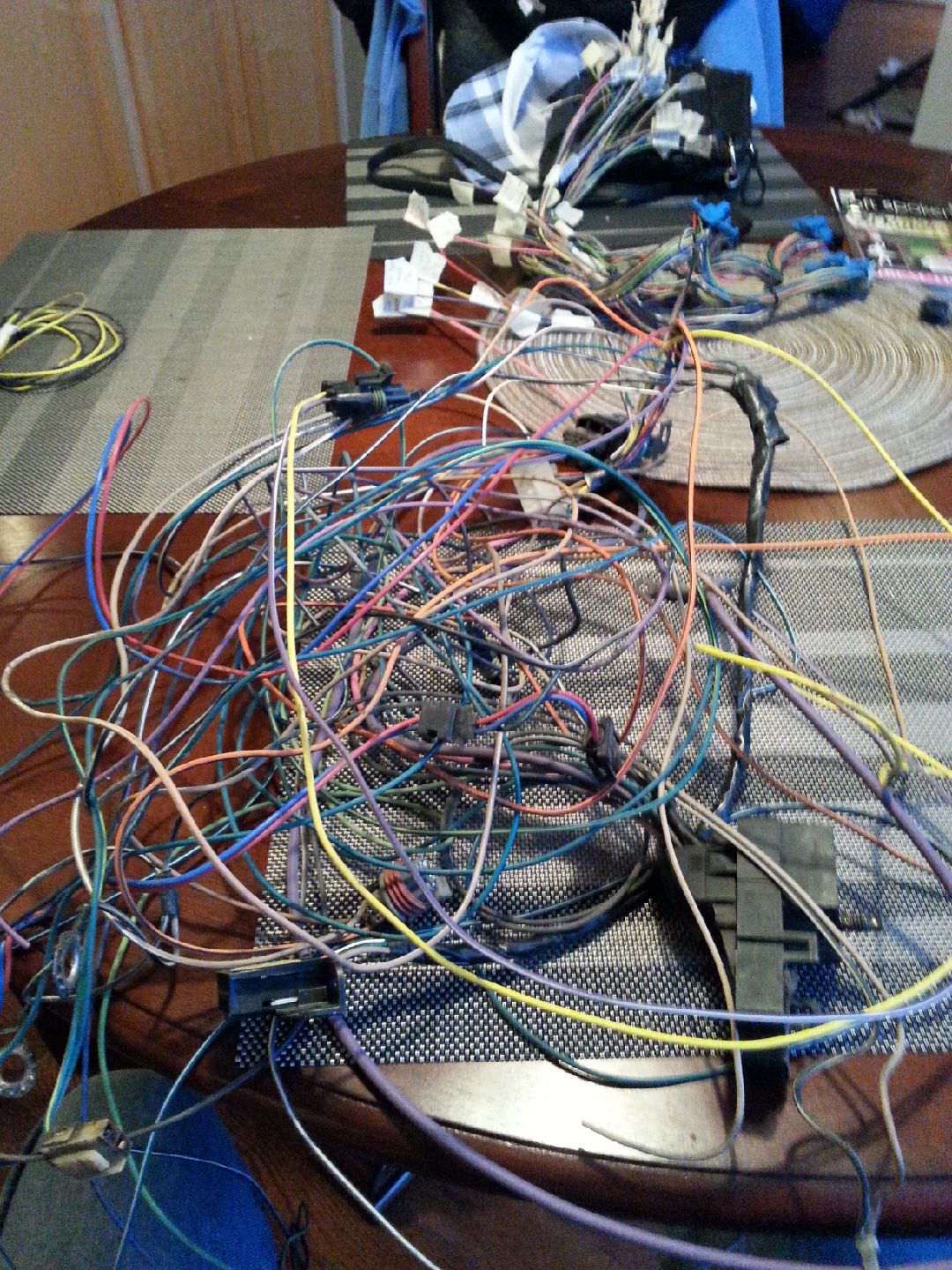

Wiring is scary when you start with a rats- nest...

But once you take the time to separate and label the wires, it suddenly becomes a relatively simple task...

|

|

|

BillS

|

NOV 11, 01:38 PM

|

|

|

You might find that transplanting a complete 3.4 V6 into the Fiero would make you happy, and that is a well travelled and probably cheaper road. The increase in torque is significant and it is an easy swap. The extra 30 bhp is welcome too, and you can massage that upward with a few mild mods during the build.

|

|

|

|