|

| Stiffer front suspension question - tires rubbing with drop spindles (Page 4/4) |

|

theogre

|

DEC 08, 02:51 AM

|

|

| quote | Originally posted by Will:

Not sure why you'd say that what's shown on the video is super involved or anything... the OTC tool is, BAR NONE, including Rodney's tool, the easiest way to separate ball joints I've EVER used.

Rodney's tool turns one end of the tool UNDER LOAD against the tip of the opposing ball joint. This galls (damages) both the end of the ball joint shank AND the cup in the tool. Also, Rodney's tool doesn't work on tie rod ends, while the OTC tool does.

Not sure why the dude in your video sprayed the entire setup down with everything under the sun... as you can see in the video, breaking the ball joint free is very easy. I also always anti-seize my ball joint tapers when I assemble them, so even moreso for me. |

|

RD is close to same as GM/KM tool. Can make the same in several ways. I make one using iron pipe fittings and screw set out of PS/WP pulley kit.

Galling the studs etc is easy to avoid even turning tool in the head of stud. If studs don't release just by turning screw, light use of hammer vibrates will pop the joint. Using a bit of grease on stud tip may help but I never need this because never tighten the screw that much to damage them.

You Should clean and lube the threads in GM RD and other press/puller tools every time there used.

Only fools lubes Taper studs. That is a good way to have BJ studs w/ major problems like can Break the stud or the hole they go into now or down the road. Nuts are not there to hold much loads, there to keep the Tapers engages when driving. Tapers take most to all loads and Must see Clean Metal to Metal Surfaces to work. Any lube on Tapers or Threads including anti-seize voids torque tables to tighten them.

Tapers in vehicles are ~ same angles as Tapers for Drill Press and Mills but those don't have nuts because doesn't get hammered by every defect on roads. Drill Press and related Tapers release easy but many fools causes problems there too.

|

|

|

Will

|

DEC 08, 08:40 AM

|

|

| quote | Originally posted by theogre:

RD is close to same as GM/KM tool. Can make the same in several ways. I make one using iron pipe fittings and screw set out of PS/WP pulley kit.

Galling the studs etc is easy to avoid even turning tool in the head of stud. If studs don't release just by turning screw, light use of hammer vibrates will pop the joint. Using a bit of grease on stud tip may help but I never need this because never tighten the screw that much to damage them.

You Should clean and lube the threads in GM RD and other press/puller tools every time there used. |

|

All of which is more involved than just using the OTC tool.

| quote | Originally posted by theogre:

Only fools lubes Taper studs. That is a good way to have BJ studs w/ major problems like can Break the stud or the hole they go into now or down the road. Nuts are not there to hold much loads, there to keep the Tapers engages when driving. Tapers take most to all loads and Must see Clean Metal to Metal Surfaces to work. Any lube on Tapers or Threads including anti-seize voids torque tables to tighten them.

Tapers in vehicles are ~ same angles as Tapers for Drill Press and Mills but those don't have nuts because doesn't get hammered by every defect on roads. Drill Press and related Tapers release easy but many fools causes problems there too. |

|

I use anti-seize on bolts where GM used Loctite. It's not a problem.

Notice, for example, that the load on the lower ball joint is pulling the taper apart, just like the Morse/Jacobs taper you mention that comes apart with a little tap.

|

|

|

ragoldsmith

|

DEC 08, 10:47 AM

|

|

Well Mitch, you hit the nail on the head! Thanks for sharing the build thread with me. Man, you guys did a lot more to the car than I realized!

|

|

|

fierosound

|

DEC 08, 01:01 PM

|

|

| quote | Originally posted by mitchjl22:

I can make this easy for you.

It has stock springs in the front. |

|

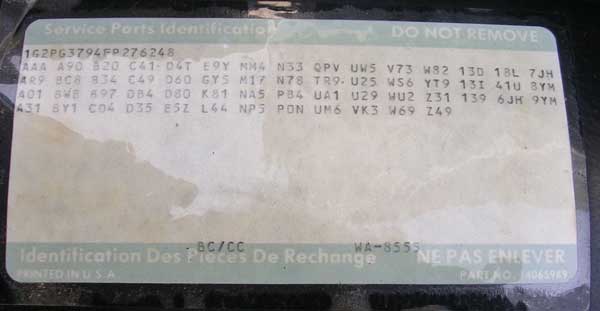

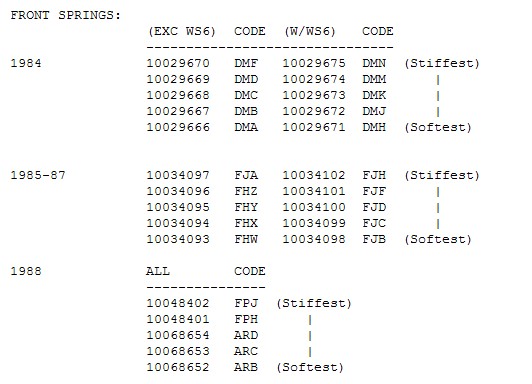

Get your spring codes from the RPO sticker in front trunk.

In the above picture, 6JH and 7JH are the front springs.

|

|

|

ragoldsmith

|

DEC 08, 07:27 PM

|

|

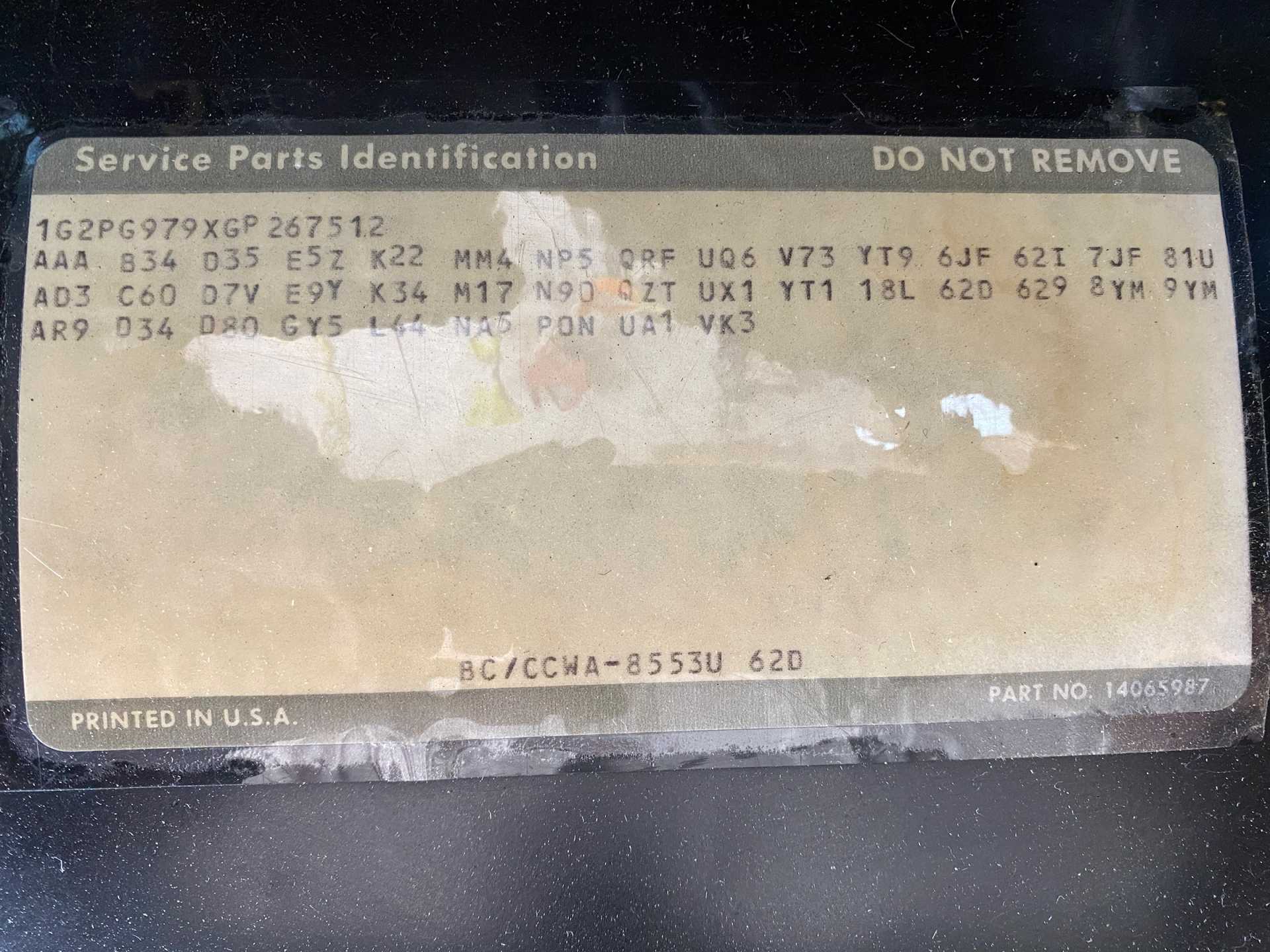

Fierosound, I'm not exactly sure how to apply the RPO sticker to the other image you posted. Here is my RPO sticker.

My best guess is that my suspension is 6JF and 7JF? Which means it's second from stiffest for 86?

|

|

|

fierosound

|

DEC 08, 07:36 PM

|

|

| quote | Originally posted by ragoldsmith:

Fierosound, I'm not exactly sure how to apply the RPO sticker to the other image you posted. Here is my RPO sticker.

My best guess is that my suspension is 6JF and 7JF? Which means it's second from stiffest for 86? |

|

Yup. Those would be a FJF set.

The FJF set would be 13 inches long.

(I no longer have these springs in the photo)

http://www.fiero.nl/forum/A...120111-2-110727.html

In my GT I eventually installed new 14 inch Chevette springs

http://www.fiero.nl/forum/A...120111-2-110255.html[This message has been edited by fierosound (edited 12-08-2020).]

|

|

|

ragoldsmith

|

DEC 09, 12:18 AM

|

|

I read through your thread a few days ago. My problem is nearly identical to yours. Unfortunately, I can't seem to find the same Chevette springs you bought anywhere. The longest ones I found were Husky at 13.63 inches. Which, honestly, would probably give me sufficient clearance, especially if it's a stiffer spring. Any idea what the spring rate is for my springs? The Husky springs are 318 pounds per inch (seems pretty high...too high for our cars?)

|

|

|

|