|

| Super Duty Four Rebuild (Page 4/6) |

|

sanderson231

|

DEC 28, 02:09 PM

|

|

|

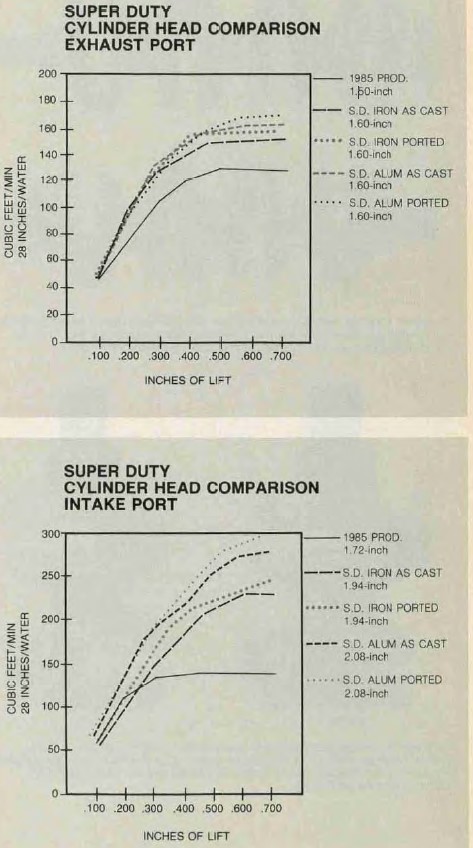

Just for comparison, the Quad 4 "086" head flows 269 cfm intake and 180 cfm exhaust at .410" lift and 28" H2O differential pressure. 0.410" lift is with the stock high output cams. Comp Cams can make a cam with 0.430" lift but that only adds a few cfm with this head. ------------------

formerly known as sanderson

1984 Quad 4

1886 SE 2.8L

1988 4.9L Cadillac

1988 3800 Supercharged

|

|

|

FieroWannaBe

|

DEC 28, 03:58 PM

|

|

| quote | Originally posted by sanderson231:

Just for comparison, the Quad 4 "086" head flows 269 cfm intake and 180 cfm exhaust at .410" lift and 28" H2O differential pressure. 0.410" lift is with the stock high output cams. Comp Cams can make a cam with 0.430" lift but that only adds a few cfm with this head.

|

|

A 4 valve head has a lot more potential for raw flow numbers, and H.O. Head was very well designed for the time. I believe the heads on my 3.4 DOHC motor are supposed to flow 261 cfm at .400 lift (I have cams reground to .396 lift.) I think the 3.4 head has a larger valve angle and lower port incline.

However most 4 valve heads are over-valved, they give up velocity for flow. And 2 valve heads are under-valved, they give up flow for velocity. The trade off is mid range torque production and port energy, which can aid in ram tuning effects. There is a video clip out there on the WWW (probably a couple, one from Paul Vanderley and one from John Callies, Where the GTP-L switch from the '801 2V head to the 4 valve Cosworth head cost the team mid-range torque and hurt overall lap times because the power band became shorter and "peaky".

The Iron head has room to improve, as it has lots of material left in the port near the head bolt pinches, that could improve flow at the top end, but port volume will increase, and that may shift peak power higher.

The aluminum head in comparison should be able to achieve flows near 300CFM at peak lift.

These heads can support lift past .800, and cams are "available" whenever cores show up, as well as older grinds, for very high lifts and durations.

The other difference in the "duke" architecture is the displacement advantage, since this engine is already at 2.7L and this particular motor could potentially achieve 2.9L of displacement, that will move the power band to lower RPMS with the available flow, making working with the worn-out and outdated Fiero transmissions a little easier, where a little broader of a torque curve can be needed, given the available ratios, compared to a Q4 Getrag and the Q4 architecture 1.8-2.4L displacements.

Other 2 Valve heads for comparison:

906 Vortec 350 heads = 240CFM @ .500 lift (260CFM Ported)

LS6 243/799 heads = 260CFM @ .600 lift (300CFM ported)

LS3 heads = 300CFM @ .600 lift (370cfm ported)

Ford GT40P heads = 200CFM @ .400 lift (250CFM Ported)

I have built up a 3.4 DOHC, I'm working on a LS4 build concurrently, and this SD4 revamp, I'm not favoring one technology over another, but just having fun trying to pull out some performance from different platforms and learning some stuff along the way.[This message has been edited by FieroWannaBe (edited 12-28-2022).]

|

|

|

sanderson231

|

DEC 28, 04:23 PM

|

|

|

Great info. I'm not trying to rain on the Super Duty rebuild parade and will follow this project closely for tips on exracting performance from a 4 cylinder. I am contemplating stroking a 2.3L Quad 4 with a Twn Cam crank. With an overbore that gets the displacement to around 2.6L. ------------------

formerly known as sanderson

1984 Quad 4

1886 SE 2.8L

1988 4.9L Cadillac

1988 3800 Supercharged

|

|

|

FieroWannaBe

|

DEC 29, 11:26 AM

|

|

To add fuel to the fire:

An un-ported K20 head will flow 295CFM at .400 lift, and over 300CFM at .500.

Ported and re-valved Kawasaki GSXR heads have surpassed 300CFM at .500 lift, and that is on a small 3.2" bore.

Ported LS3 or Gen II Hemi heads can approach 370 CFM over .600 lift

The head flow is one factor (a big one) in the engines ability to make power, more flow, more power.

Modern heads are better, bigger, and have great ECUs to make things work in almost all conditions, and some high tech roller cam designs, with wide LSAs to keep things behaved for day to day driving. This engine isn't going to be one of them.

In order to predict where in the RPM band the peak torque, and subsequent power, will be made we need to factor in displacement, port velocity (energy), cam shaft timing, and how ram tuning affects it all. Big flowing heads by their nature have big ports, big ports require large volumes of air to start making the ram tuning effective, via a higher velocity of air. This means any motor will make more power in higher RPMS with bigger ports compared to smaller ports which will reach peak velocities at a lower airflow, and choke at high RPMs, limited top end power.

As I piece my engine together I am trying to pay close attention to all the factors I can control to enhance power in the range I think best suits the application, A street motor with some time spent on a race track turning laps. I want an engine with a broad torque curve that can breath well at the upper RPM band. There will still be a 4 speed behind this, so it will have some hefty splits at each shift, so a peaky motor isn't ideal, and exceeding 7000 RPM will make the shifts much harder to accomplish with the sluggish synchro's.

The Iron head has a 180cc intake port, for the time it was released, this in on the higher end for it's bore, but not exceedingly large, this is the size port a lot of hot 350s have, and much larger than most factory ports, especially in the 1980s. The aluminum heads as cast have a port of 178cc, and will only become larger as the bowls and throats' of the port are finished, so I don't plan on porting it any larger than necessary to achieve to flow needed for my power-band goals even though it has lots of room to grow.

|

|

|

sanderson231

|

DEC 29, 12:52 PM

|

|

| quote | Originally posted by FieroWannaBe:

There is a video clip out there on the WWW (probably a couple, one from Paul Vanderley and one from John Callies, Where the GTP-L switch from the '801 2V head to the 4 valve Cosworth head cost the team mid-range torque and hurt overall lap times because the power band became shorter and "peaky".

|

|

Interesting and certainly matches my experience with the Quad 4. Great from 4000 rpm to 7000 rpm. 2000 to 4000 rpm needs improvement. A reason I think that going from a 85 mm to 94 mm stroke with the Twin Can crank will bring more overall performance than one might expect from the displacement increase.

------------------

formerly known as sanderson

1984 Quad 4

1886 SE 2.8L

1988 4.9L Cadillac

1988 3800 Supercharged

|

|

|

FieroWannaBe

|

JAN 03, 11:50 AM

|

|

Because my car was an 84, it had a V-belt accessory drive, Pontiac did not have a harmonic damper on the Iron duke at this time, and the owner did not have the Super duty balancer installed.

I did find hunting through rock auto and google image search, that a mid 60's-70's Chevy 250CI I6 balancer, looks very similar the Super Duty Balancer. The bore measured out to the needed 1.248.

https://www.rockauto.com/en...12&jsn=1&jsn=1&jsn=1

This balancer has what looks like a correct spacing for the V belts, This is for a 1967 Chevy C10, w/o AC, and not HD cooling. It even came in with a nice Black Oxide finish.

It will need a new TDC mark added so it can be used with the Duke Pointer.

|

|

|

fieroguru

|

JAN 04, 06:54 AM

|

|

|

If you wanted to run a serpentine setup, the 89+ dukes as well as the 87+ FWD 2..8/3.1 balancers switched to serpentine setup and will fit.

|

|

|

FieroWannaBe

|

JAN 04, 10:32 AM

|

|

|

I really wanted to avoid the addition of sourcing new AC compressor to switch to serpentine.

|

|

|

fieroguru

|

JAN 04, 05:56 PM

|

|

|

You can just swap the clutch/pulley.

|

|

|

FieroWannaBe

|

JAN 05, 05:37 PM

|

|

|

I will have to keep that all in mind down the road, if I find the I6 balancer lacking.

|

|

|

|