|

| The White Bug (Page 43/46) |

|

ericjon262

|

JUN 03, 09:22 PM

|

|

Congrats, the car looks great!

|

|

|

jumpmonkey

|

JUN 05, 01:55 PM

|

|

|

Looks awesome! You've put in a mighty amount of effort for this build.

|

|

|

pmbrunelle

|

JUN 07, 08:12 AM

|

|

Thanks!

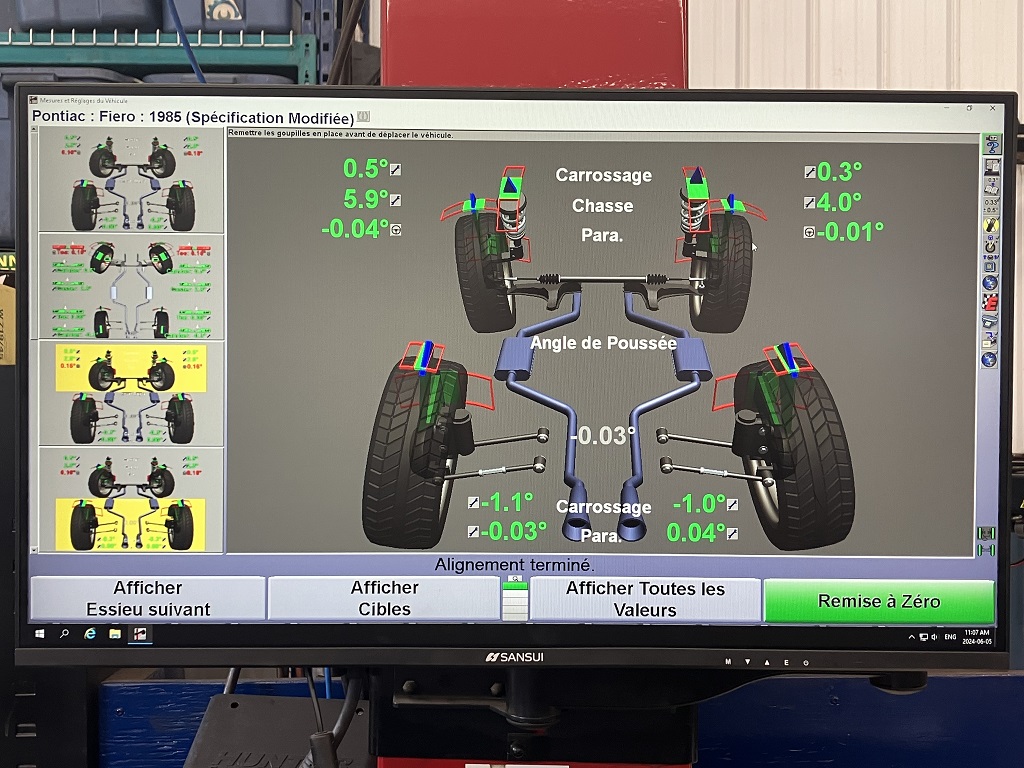

Next steps are to try and make the caster more equal on both sides:

After that, increase the engine's boost pressure with water injection.[This message has been edited by pmbrunelle (edited 06-07-2024).]

|

|

|

pmbrunelle

|

AUG 21, 12:10 AM

|

|

Alignment-wise, I swapped around the washers on the UCAs to get the same caster between the left and right sides of the car.

I also decided that I liked toe-in for stability while braking.

********************************************************************************

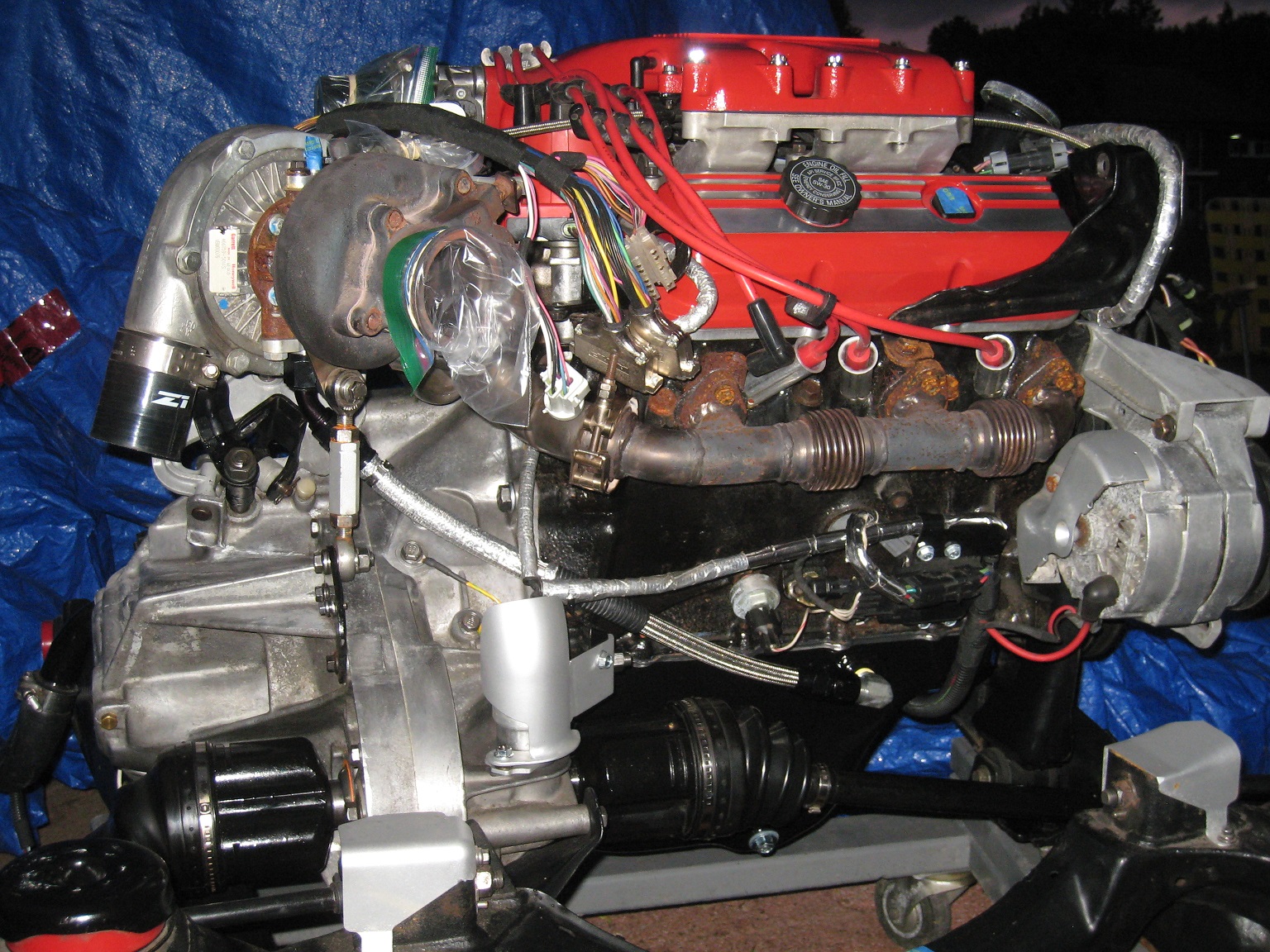

For a few weeks this summer I wasn't able to drive my Fiero.

When the engine was stopped, I did an incorrect manipulation with my laptop computer in TunerStudio, and I (unknowingly) injected water into the engine while it was stopped. When I tried to restart the engine, I hydrolocked it and busted the starter and ring gear.

The engine had to come out to replace the flywheel!

As I shopped for replacement flywheel bolts (a good practice to replace heavily tightened bolts on a critical joint), I figured out that I had been running the wrong bolts; I had been using flexplate bolts for an automatic transmission Fiero. Back in the day, I reused (without thinking too much) the bolts from my manual transmission donor car that the previous owner installed (never trust previous owners).

The flexplate is thinner than the flywheel, so automatic transmission cars use shorter bolts in that location. I used ARP 102-2803 for the Nissan SR20DE/DET.

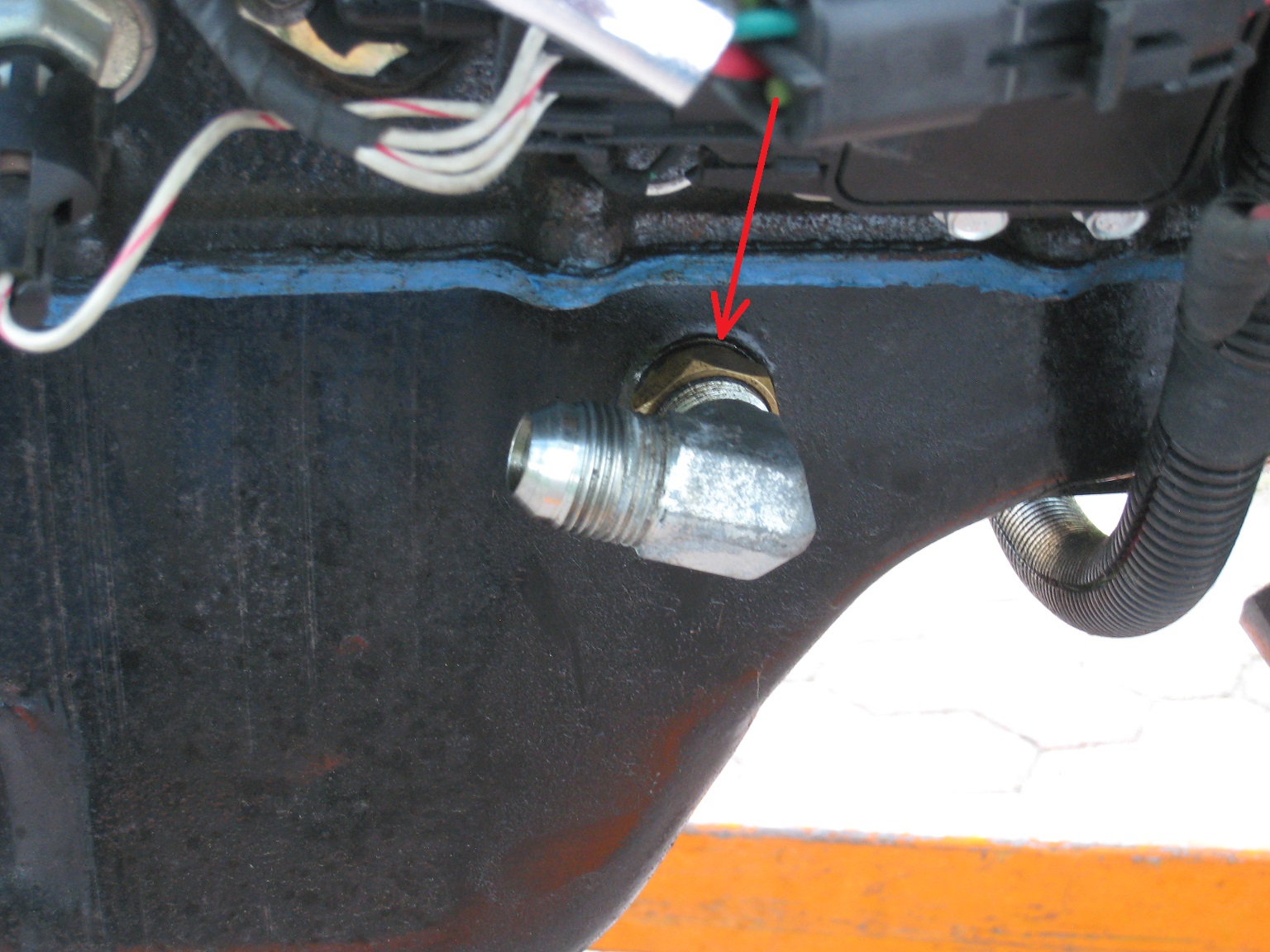

Upon reassembly, I then noticed that the solder joint of my brass turbo oil drain fitting had cracked. This was a fire risk and needed to be addressed. Good thing I saw it...

I installed a 1/2" NPT wide-flange weld-on bung from Tanks, Inc.

https://www.tanksinc.com/in...mode=prod/prd787.htm

Since the oil pan was off, I was able to see that the connecting rods were still straight and had the usual endplay. Looks my my hydrolock incident didn't damage anything...

With the oil pan installed:

Then, continuing assembly, I noticed that my rubber turbo oil drain hose had burned in one area from radiation from my Y-pipe:

I made a replacement line from PTFE hose, and I installed a fibreglass reflective heat sleeve over the heavily radiated area:

Here is the oil drain line installed:

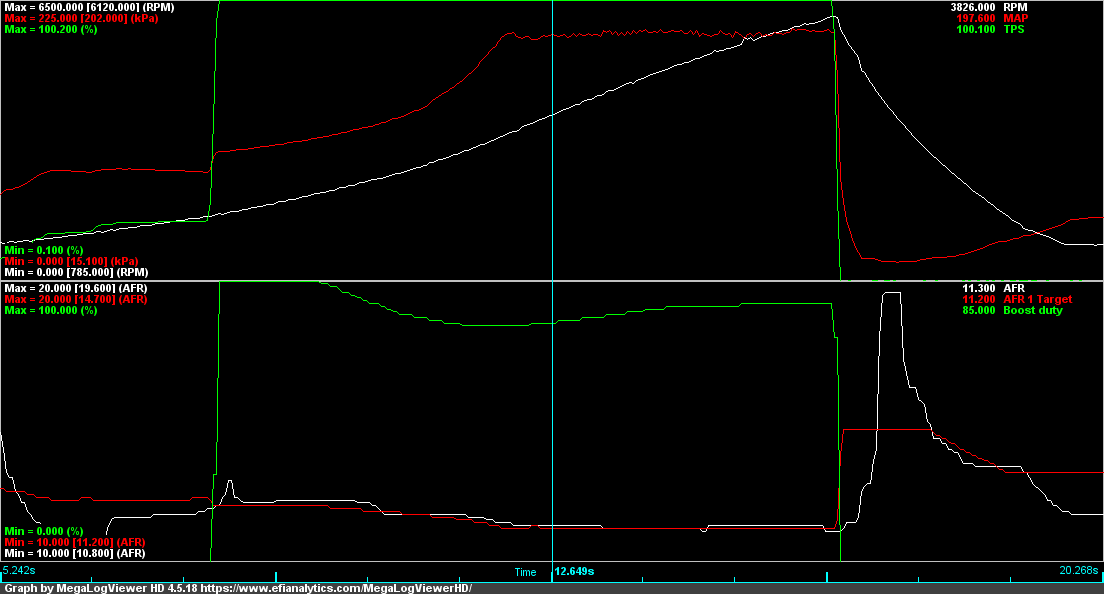

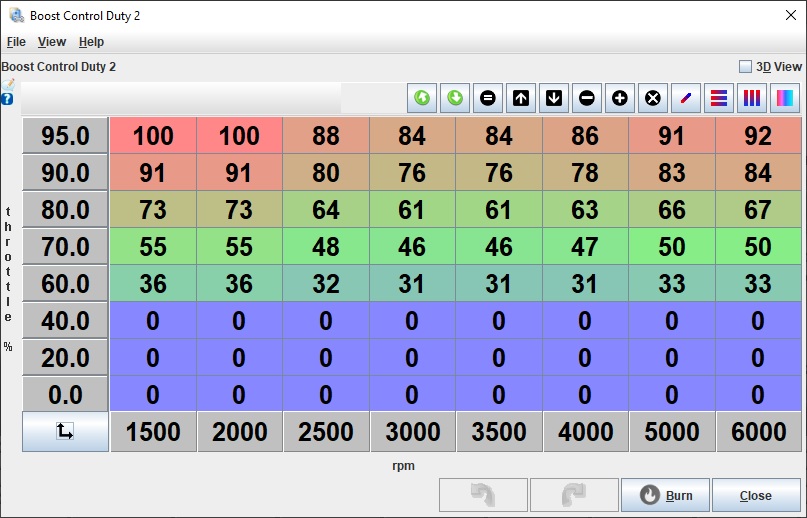

Now that I managed to get the water injection working without hydrolocking the engine, I did myself a 200 kPa MAP tune:

I am currently using open-loop boost control.

Manifold pressure is not stable with temperature (perhaps 15 kPa more pressure in colder weather), and also varies depending on gear.

My next step is to set up closed-loop boost control in order to stabilize the manifold pressure.

Once I have a good closed-loop boost control, then I think I can try increasing the boost.

I expect to replace the springs in the wastegate actuator for a stiffer spring, as the boost control solenoid duty already reaches 92%.

|

|

|

pmbrunelle

|

SEP 05, 08:50 PM

|

|

I set up closed-loop (PID + feedforward) boost control; it works fine.

I did some tests at 210 kPa MAP yesterday, but the engine didn’t run correctly at that manifold pressure. I think I was experiencing spark blowout.

I set the manifold pressure back to 200 kPa, and the engine went back to running normally.

Later, I think I could reduce the spark plug gaps, and then retry higher manifold pressures.

************************************************************

I killed the 3rd gear of my Franken-Muncie (1984 M19 gears in V6 ribbed case).

I need to decide if I want to put another (were the V6 gears stronger?) Muncie in its place, or perhaps a Getrag F23.

Getrag F23 is a bigger project, with some concerns:

On some online pictures, there is an oil fill cap above the bellhousing. It looks like a crossover pipe will run right above that.

The case doesn’t appear to have many bosses to install transmission mounts front and rear Fiero-style.

I need to do some more research on this topic.

|

|

|

82-T/A [At Work]

|

SEP 06, 09:11 AM

|

|

|

I love the way this is coming out. And the way you're doing it is very professional, and stock looking.

|

|

|

La fiera

|

SEP 09, 03:12 PM

|

|

|

|

ericjon262

|

SEP 16, 01:53 AM

|

|

my car has an F23. I've never driven a 4 speed Fiero, so I can't make comparisons to that, however, I have driven my car with both a 3.63 final drive, and a 3.94, unfortunately, the gear ratio wasn't the only change, and it was probably a year apart. I do remember the 3.94 rapping out quickly, IIRC the one I had in the Gran Damn would routinely get put in fourth at sub 30 MPH, and still be able to reasonably accelerate to highway speeds.

I have a metric, and ecotec F23 in the garage that I plan to take apart soon and build a backup for my car, if you need measurements or pictures, let me know.

There's also the F40, but it has a whole list of issues to install in a Fiero. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

I invited Lou Dias to trash me in my own thread, he refused. sorry. if he trashes your thread going after me. I tried.

|

|

|

pmbrunelle

|

SEP 17, 08:22 AM

|

|

I bought an F23 from a 2000 Pontiac Sunfire:

I guess I now have a winter project to put it in the car!

Front transmission mount seems tricky to implement in the stock Fiero location, from lack of mounting bosses on the transmission case. I see why 262 uses a flat metal plate on the bellhousing with a transmission mount relocated on the crossmember.

Just from looking at the stock ratios I think I will like it; it is a has a similar kind of gearing as my M19 gearing with a low 1st gear to help econobox engines move a car off the line. The F23 also has fancy double-cone synchros, etc.

I think the 4-speed Muncie synchros are not so great; shifting feels like it takes forever in the higher RPMs (especially 1->2) when I'm in a hurry. Perhaps my metallic clutch disk has more inertia than a stock disk, exacerbating this issue.

| quote | Originally posted by ericjon262:

I have a metric, and ecotec F23 in the garage that I plan to take apart soon and build a backup for my car, if you need measurements or pictures, let me know.

|

|

I will keep that in mind, thanks.[This message has been edited by pmbrunelle (edited 09-17-2024).]

|

|

|

Will

|

SEP 19, 08:27 AM

|

|

The metric bellhousing F23 has a 3.94 final drive.

IIRC:

The Ecotec F23s have 3.84 final drive

The early Cobalt XFE transmissions have a 3.73 final drive

The later Cobalt XFE transmissions have a 3.63 final drive.

The early HHR transmissions have a 4.17 FD, and the Vue transmissions have a 4.41.

All boxes have the same shifted gears, except the Vue which has a 0.81 fifth.

The 3.63 transmissions have very nearly the same overall ratio set as the Fiero 282.

The bellhousing side of the differential housing has FAR more bracing on the F23 than it does on the 282... The most common failure mode of the 282 seems to be breaking the differential bearing out of the case on that side due to axial loads from the final drive mesh.

I have noticed the same things you have about mounting the metric bellhousing transmission "Fiero style". I was expecting that I'd grab the front mount bracket from https://thelinsellsdotcom.wordpress.com/ (or is it https://thelinsells.limitedrun.com/ ?) and add to/modify it to pick up some other bolt holes on the bellhousing.[This message has been edited by Will (edited 09-19-2024).]

|

|

|

|