|

| The Turbo 3500 F23 swap (Page 50/81) |

|

ericjon262

|

MAR 11, 06:43 PM

|

|

| quote | Originally posted by pmbrunelle:

Recall Newton's second law of motion, as an equation:

F = ma

|

|

while I agree that that is newtons second law, you can't disregard his third law:

"all forces between two objects exist in equal magnitude and opposite direction"

there is still applied force, regardless of acceleration, net force is 0, because the chassis is exerting the same force back to resist the motion.

|

|

|

pmbrunelle

|

MAR 11, 09:19 PM

|

|

When we speak of the net force acting on a body to determine its acceleration, we mean the sum of external forces acting on said body.

Implicitly, per Newton's 3rd law, the body reacts to the external forces with corresponding equal and opposite reactions... i.e. the powertrain torques the axles one way, while the axles torque the powertrain the other way.

When we tally up the "net" force acting on a body, we exclude the internal reactions of the body to the external forces.[This message has been edited by pmbrunelle (edited 03-11-2020).]

|

|

|

ericjon262

|

MAR 12, 07:41 PM

|

|

| quote | Originally posted by pmbrunelle:

When we speak of the net force acting on a body to determine its acceleration, we mean the sum of external forces acting on said body.

Implicitly, per Newton's 3rd law, the body reacts to the external forces with corresponding equal and opposite reactions... i.e. the powertrain torques the axles one way, while the axles torque the powertrain the other way.

When we tally up the "net" force acting on a body, we exclude the internal reactions of the body to the external forces.

|

|

the axle applies force to the mounts via the engine block and transmission case, the force applied has to go somewhere, or else the wheels don't turn. what you're saying, is that if I put a wrench on a stuck bolt and try and turn it, without turning it, I apply no force because there is no acceleration, which couldn't be further from the truth, the force applied is resisted by an equal and opposite force.

example, stand on your bathroom scale, it reads out in a pounds force, you stand there perfectly still, and there is no longer acceleration, yet your body still exerts xxx pounds on the scale. is the downward force applied by your body 0 because there is no acceleration? no, the scale applies the same force upwards resulting in a net force between you and the scale of 0.

for a practical example, get a holesaw and a 2x4, try and use the holesaw to put a hole in the 2x4 6" from one end, and 18" from the other. you'll find that it is significantly easier to hold the board steady from 18" away vice 6" away. this practical experiment substitutes the holesaw for the axle, and the 2x4 for the mount, and your hand for the chassis side mount. the force applied to hold the board will be inversely proportional to the distance from the centerline of rotation.------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

"The day I tried to live, I stole a thousand beggars' change and gave it to the rich."

http://www.fiero.nl/forum/Forum2/HTML/119122.html

|

|

|

pmbrunelle

|

MAR 12, 11:33 PM

|

|

| quote | Originally posted by ericjon262:

what you're saying, is that if I put a wrench on a stuck bolt and try and turn it, without turning it, I apply no force because there is no acceleration, which couldn't be further from the truth, the force applied is resisted by an equal and opposite force.

|

|

I wasn't saying that, but it is possible that I lack the communication skills to correctly convey my ideas on an online forum.

********************************************************************************

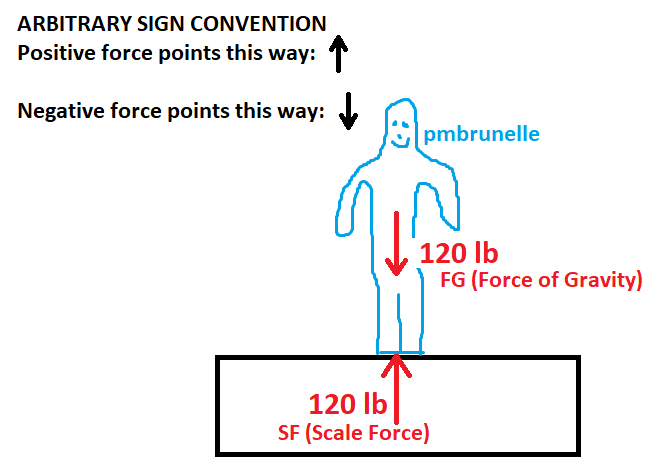

Here is a schematic (we can call this a free body diagram) of me on a scale to allow for discussion:

| quote | Originally posted by ericjon262:

example, stand on your bathroom scale, it reads out in a pounds force, you stand there perfectly still, and there is no longer acceleration

|

|

That's good so far.

| quote | Originally posted by ericjon262:

yet your body still exerts xxx pounds on the scale.

|

|

That's correct, the soles of my feet are pushing down on the scale. Notice that I have omitted this force from my free-body diagram. In the free-body diagram, we only indicate external forces that act on the body.

| quote | Originally posted by ericjon262:

is the downward force applied by your body 0 because there is no acceleration?

|

|

I didn't say that.

| quote | Originally posted by ericjon262:

no, the scale applies the same force upwards

|

|

I agree, you'll see the scale force of 120 lbs upwards in the diagram.

| quote | Originally posted by ericjon262:

resulting in a net force between you and the scale of 0.

|

|

Indeed, the scale will push up on me as much as I'm pushing down on the scale. That's a trivial consequence of Newton's 3rd law.

However, this is not a correct usage of the term "net force".

Here is how the "net force" acting on a body is summed up (in this case, with two external forces that happen to be known), using pmbrunelle on the scale as an example:

Net force = SF - FG

notice that FG has a minus sign in front of it, because the arrow is pointing downwards.

Substituting variables for true values:

Net force = (120 lb) - (120 lb)

Simplifying:

Net force = 0 lb

From:

a = F / m

where "F" is the net force acting on the body

We can conclude that my body is not accelerating (a = 0), because the net force acting on it is 0 lb.

********************************************************************************

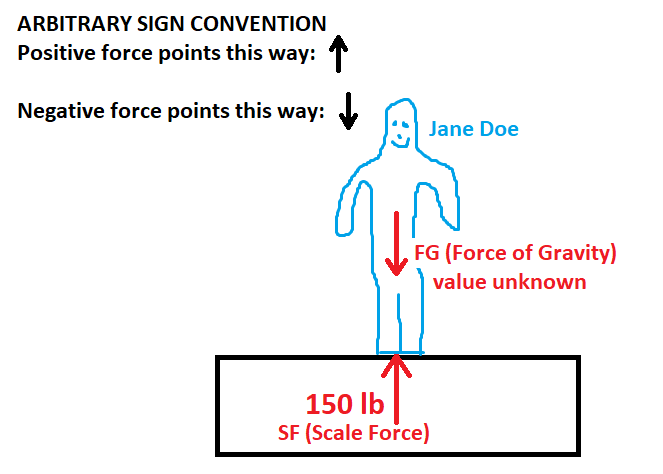

Statics is the study of mechanics where bodies are not accelerating (a = 0).

When a body is not undergoing acceleration, we can say that the net force acting on it is equal to zero. If for some reason we happen to know that the net force acting on a body is equal to zero, this may allow us to solve for unknowns more easily.

Lets apply statics to find out the weight of Jane Doe:

Since Jane Doe is standing still, she is not accelerating, thus the net force acting on her is 0 lb.

For the moment, we know know the scale's measurement. We don't know her weight; that's what we want to find out.

Net force = SF - FG

0 lb = SF - FG

0 lb = 150 lb - FG

FG = 150 lb

From the knowledge that Jane Doe was not accelerating, we were able to conclude that she weighs 150 lbs.

So that's an example of a statics problem with forces acting in one axis.

********************************************************************************

A hole saw situation cannot be directly compared with a driveaxle situation, but I do not have the time to explain right now. Maybe in the weekend.[This message has been edited by pmbrunelle (edited 03-12-2020).]

|

|

|

ericjon262

|

MAR 17, 12:05 AM

|

|

|

|

ericjon262

|

MAR 21, 02:37 PM

|

|

a nice update, my header flanges arrived. I have some changes to make to the design before the DWG goes public. I'm also going draw up 2 other pipe sizes, and dies to form the pipe.

I have some pictures to compare mine to the "off the shelf" flanges. Noteworthy points, the strap holding the port flanges together can cause interference with the spark plugs. The Stainless headers(SH) flange has really poor spark plug clearance, the BCC flange is much better, and my flange offers the most clearance, but admittedly, the difference in clearance between mine and the BCC isn't enough to make a significant difference.

Here's some close ups of the ports. if you want an off the shelf flange, the BCC is by far the way to go, the SH flange if junk IMO. I have a few simple changes to make to my flange, that aren't anything really even visible here, the tolerance of the laser, and the tolerance in my drawing results in the bolts being a little bit too tight. I also want to change some of the contours ever so slightly. I'll also draw it for 1.5" OD tube, 1.625" OD tube, and 1.75" OD tube, as well as a die for forming the tubes. once I have them drawn, I'll post a link for downloads.

Here are examples of each port's shape compared to the port shape. you can see the SH port is all over the place, even overlapping at points, total garbage. the BCC flange is way better, but only available in mild steel...

1st port:

2nd Port

3rd port

big picture:

I'm going to focus the rest of today on getting the decklid hinges completed, then I'll start one of the manifolds. I started one of them last night, but got a little heavy handed with the grinder and will need to get more material before I can complete both. I put a ton of orders in for material and parts over the last week, to include a new turbo, this one, a precision 6266 CEA gen 1, and a Turbosmart comp gate 40mm wastegate I also ordered the pipe for the remainder of the hotside. Hopefully next week shows some real progress once that parts all roll in. ------------------

"I am not what you so glibly call to be a civilized man. I have broken with society for reasons which I alone am able to appreciate. I am therefore not subject to it's stupid laws, and I ask you to never allude to them in my presence again."

cognita semper

http://www.fiero.nl/forum/Forum2/HTML/119122.html

|

|

|

ericjon262

|

MAR 22, 12:57 AM

|

|

|

|

fieroguru

|

MAR 22, 09:06 AM

|

|

Great job and attention to detail on the header flange!

It makes you wonder if the guys making the other header flange ever looked at one of the heads. To me it looks like they just copied the bolt pattern, slapped what ever hole geometry they had over the power location and called it a day. I have a set of cheapo stainless steel headers for the LS and the bolt pattern on several holes is off 1/8"... like they made it from a picture vs. using an actual head.

|

|

|

Joseph Upson

|

MAR 22, 10:21 AM

|

|

| quote | Originally posted by fieroguru:

Great job and attention to detail on the header flange!

It makes you wonder if the guys making the other header flange ever looked at one of the heads. To me it looks like they just copied the bolt pattern, slapped what ever hole geometry they had over the power location and called it a day. I have a set of cheapo stainless steel headers for the LS and the bolt pattern on several holes is off 1/8"... like they made it from a picture vs. using an actual head. |

|

Perhaps that is the wrong flange and is intended for the 3500/3900 VVT motors, their manifolds are not interchangeable with the 3400/3500 non VVT motors and that may account for the fitment issues.

|

|

|

ericjon262

|

MAR 22, 11:40 AM

|

|

| quote | Originally posted by fieroguru:

Great job and attention to detail on the header flange!

It makes you wonder if the guys making the other header flange ever looked at one of the heads. To me it looks like they just copied the bolt pattern, slapped what ever hole geometry they had over the power location and called it a day. I have a set of cheapo stainless steel headers for the LS and the bolt pattern on several holes is off 1/8"... like they made it from a picture vs. using an actual head. |

|

Thanks, I put a ton of work into them, I have a little more to do, then i'll post the DXF/DWG so that people can have them made.

| quote | Originally posted by Joseph Upson:

Perhaps that is the wrong flange and is intended for the 3500/3900 VVT motors, their manifolds are not interchangeable with the 3400/3500 non VVT motors and that may account for the fitment issues. |

|

the VVT engines use a completely different bolt pattern, the port shape is also a little different. The company also doesn't sell flanges for the VVt engines, I think these guys were just lazy.

|

|

|

|