|

| Measuring HTOB to determine need for spacer? (Page 1/4) |

|

FieroGT42

|

FEB 23, 12:57 PM

|

|

Getting ready to install my flywheel, clutch and F23 on a stock 2.8. I haven't done a swap before so I'm not sure how everyone's measuring this, what's okay and what isn't. Thanks in advance for any help.

Jason

|

|

|

FieroGT42

|

MAY 27, 03:41 PM

|

|

|

Anybody? I know I found a thread on some forum at one point that gave very clear descriptions on how to measure what and the formulas used, but I can't seem to find it now.

|

|

|

fieroguru

|

MAY 27, 04:19 PM

|

|

First measurement: Distance from the bellhousing face to the tips of the pressure plate fingers. With the clutch/pressure plate bolted/torque to the flywheel, place a straight edge across the center of the pressure plate and measure the distance from the edge of the straight edge to the bellhousing face. If the fingers are recessed below the surface of the pressure place, measure that distance and subtract it from the previous measurement.

Second Measurement: Distance from the bellhousing face to the fully extended end of the HTOB. Install the hard line (or plastic bleeder fitting) to the HTOB to disengage the check valve (this is a critical step and where many people mess up). Let the spring in the HTOB fully extend it while you place the straight edge across the center of the bellhousing. Measure the distance from the bellhousing face to the fully extended HTOB.

Third Measurement: Distance from the bellhousing face to the fully compressed HTOB. It helps if you clamp your straight edge in place, as you will need 1 hand to compress the bearing and the other hand to take the measurement. Measure the distance from the bellhousing face to the fully compressed HTOB.

The difference between the 3rd and 2nd measurement is the normal range of motion of the HTOB. The first measurement must be between the 2nd and 3rd and ideally it would be 2/3rds of the distance from the second one and 1/3rd the distance from the 3rd one. As the clutch wears, the fingers will go closer to the HTOB, so you need to keep 1/3 of the range of motion for clutch wear and 2/3's for clutch release.

For example (not real numbers, just keeping the math easy to follow): say your clutch fingers are at 2.0" and the extended HTOB is 1.5" and the compressed HTOB is 2.25. The range of motion is 2.25-1.5 = 3/4". There is 2.0-1.5 = .5" of available travel to release the clutch. 2.25-2.0 = .25" of available travel for clutch disk wear, and 2/3 of the available travel is for release and 1/3 of the available travel is for wear.

Some may argue that you should have a 50/50 split to maximize the wear life of the clutch and that could work, but I think 66/33 is a safer place to avoid the chance of over extending the HTOB.

I walked through this process in my LS4/F40 swap, but it also had to take into consideration spline placement and engagement since the input shaft is about 1" into the bellhousing. Not an issue for the F23.

| quote | Originally posted by fieroguru:

There has been lots of discussions lately about the proper measurement of the range of travel for the F40 HTOB. So here are the following measurements - all measurements are distance from the Bellhousing Flange:

End of Input shaft: 1.121"

End of Splines: 1.502"

HTOB fully extended: 2.675"

HTOB fully compressed as delivered: 3.218"

HTOB fully compressed with the bleeder screw opened: 3.582'

The F40 HTOB has a check valve inside it. So the amount of fluid in the HTOB from the factory is trapped and will not allow the HTOB to fully collapse until the bleeder assembly is installed and the bleeder screw opened. Once you bleed off the factory fill, you get an extra .364" of travel to the back side and the overall range of travel increases to .907" (from .543").

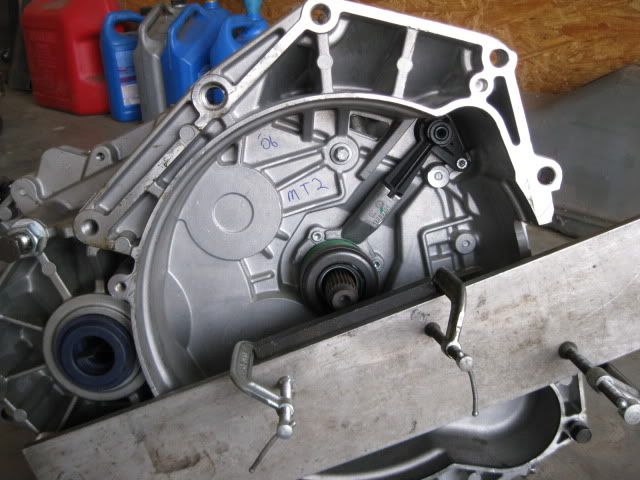

Here is the setup I used to get these measurements with my digital calipers:

|

|

[This message has been edited by fieroguru (edited 05-27-2013).]

|

|

|

FieroGT42

|

MAY 27, 07:57 PM

|

|

"I see" said the blind carpenter, as he picked up his hammer and saw.  Thanks, it seems pretty obvious now. My trip through KY has been cancelled or I'd buy you a beer, so I'll just have to owe you one. Thanks, it seems pretty obvious now. My trip through KY has been cancelled or I'd buy you a beer, so I'll just have to owe you one.

|

|

|

joshua riedl

|

MAY 28, 10:57 AM

|

|

|

I'm going through the same thing right now so ill post my numbers. It would be great if you put yours up when you get them to compare. For the tob I have 1.89 extended and 2.75 compressed for .86" available travel. Cutch fingers to mounting surface I have about 2.19". The fingers measure different on every one so I picked an average number. I'm thinking about a .25" spacer added to the 2.19" clutch reading is 2.44". Subtract the extended number gives me .55" available TOB travel. I could probably go thicker on the spacer but I was having an over travel issue with the spec clutch before so I don't see the point on pushing the limits. Ill be curious to see what you come up with.

|

|

|

FieroGT42

|

MAY 28, 06:48 PM

|

|

Will do but it might take me a week or so to get to that point. I'll post and PM you when I do.

Never mind. The rest of what I needed came in the mail. BTW, this is on a stock 2.8 with a flywheel #6505 from Standard Flywheels and replacement pressure plate.

F23 HTOB measurements

1. Engine side, Pressure plate fingers to bellhousing face 2.260” 2.310"

2. Trans side, HTOB extended to bellhousing face 1.900”

3. Trans side, HTOB compressed to bellhousing face 2.675

Derived measurements:

A. 2.675 – 1.900 = 0.775” travel

B. 0.775 / 3 = 0.258333 per third of the travel

C. 0.245 * 2 = 0.51666 for 2/3 travel

The HTOB should not extend (on my car, with my measurements) more than 0.775” from its compressed state, which is 1.900” from the where the engine & transmission bellhousing faces mate.

Is the disengagement travel calculated from where the HTOB makes contact with the fingers?

2.310 - 1.900 = 0.410" HTOB-fingers clearance when compressed.

0.775 - 0.410 = 0.365"of throw for disengaging

0.445" / 0.775 = 47% of the total HTOB throw is after the HTOB meets the fingers.

With 1/4" spacer:

0.410 - 0.250" spacer = 0.160 air gap & clutch wear

0.615 of throw for disengaging

0.615 / 0.775 = 79%. 2/3 would need 0.152" spacer

Jason[This message has been edited by FieroGT42 (edited 06-01-2013).]

|

|

|

trotterlg

|

MAY 28, 08:44 PM

|

|

|

There are other clutch plates which have fingers that are higher than one from a Fiero. A pressure plate from a Chevy 2.2 bolts to the same flywheel as a fiero but has fingers about 1/4 to 5/8 highter, same diamerter disc. There are probably a lot of ways to solve this problem without resorting to shims. Larry

|

|

|

joshua riedl

|

MAY 28, 08:55 PM

|

|

|

At least the measurements are fairly consistent. I actually think I could get away without a spacer but just barely and I'm not going the chance it. TOB's are expensive for these transmissions. I called today to order one but they were closed for the holiday. I don't know if you got that far but autozone had a 12mm x1.0 coupler that I'm going to braze to the hydraulics to hook up the stock line.

|

|

|

FieroGT42

|

MAY 28, 09:54 PM

|

|

I just figured out what I'm doing for that the other day. I'm just waiting on the part to arrive so I can confirm it fits before I go running my mouth about it and having people upset that it doesn't fit.

I think I found a one-piece German OEM part that has the quick disconnect we need on one end and a threaded fitting on the other (undoubtedly metric, maybe even 12mm x 1.0) connected with flex hose. Plus it was about $25 vs $40 for one made by a PFF member or the $80 that I saw some J-body enthusiasts paying. I plan to run my own clutch line since I'm swapping auto-to-stick, so I'm hoping that will take care of my flex hose and HTOB hydralics in one shot. Plus hey, it's German OEM quality. That's hard to beat.

Edit: Should know Thursday[This message has been edited by FieroGT42 (edited 05-28-2013).]

|

|

|

trotterlg

|

MAY 28, 11:10 PM

|

|

I have this sitting here, on the floor not bolted down the fingers are 2.050 from the cement. bore is 2.080 or so. It is close to new, I could bolt it to a FW with a plate and measure the height, it is yours for the shipping it will fit a large flat rate box which I think ships for about $16.00. Larry

|

|

|