|

| The flywheel bolt solution for 3800 (l67 & l32) swaps (Page 1/5) |

|

BV MotorSports

|

JAN 26, 08:24 PM

|

|

THIS IS A GUIDE. It works for my 460whp 3800. Like it, use it. Don't like it, don't use it.

Got a 3800 swap? Do you have a manual trans? If so, read on. I have shared this info with only DH and John at Intense Racing. John was really excited and passed the info on to Brunton (Stalker kit car maker).

So getting rather annoyed with my flywheel bolts backing out I came up with a permanent solution to the problem. Toss those stupid hardware & chevy cam bolts in the trash. Here is the absolute remedy. I spent 2 hrs on the phone with Art at ARP. That guy is amazing. We had several different options:

alexc@arpfasteners.com

ARP special order

Hi Steven,

Thank you for your interest in ARP's Specialty Products Department.

Below is the price information you requested for your custom fasteners.

Qty. 40

*3AG1.000-10CL

Price $20.92 ea

(5/16-18 x 1.000” 12-point bolt | .620” head collar OD | Custom Age 625+ material)

We would recommend 32-34 ft/lbs on these with our ARP Ultra-Torque lubricant.

Thats 1 option. Not happy with the idea of $21 a piece bolts that hold only 32ftlbs. Thats 10ft-lbs more than those hardware store or cam bolts. I asked if they had anything better. The reply was they could make bolts in the above diameter that could take 55ftlbs but it would be ATLEAST double the price. Next....

I asked if we could go to a 3/8ths bolt. Unfortunately 5/16th and 3/8ths overlap. LAME! Art suggested 10mm. He crunched the numbers and sure enough, 10mm cuts all new threads! YES! Art checks his inventory and found the following:

Nissan 2.0L (SR20DE/DET)

Flywheel Bolt Kit Kit #: 102-2803

UHL 0.925˝

Thread Size M10 x 1.00

Wrenching 5/8

ARP's instructions for installing the above bolts & TQ spec

PERFECT!!!!! They are a stock item. Click here for the bolts

You will need a 9mm hardened drill bit. A 10mm x 1.00 starting and finishing tap. I ordered these from http://www.mscdirect.com/ since no one has metric drill bits & taps in stock around here. Patience and lots of WD40.

Drill the flywheel holes 10mm.

Bolt the flywheel on with one of those stupid hardware store bolts or cam bolts.

Using the flywheel as a guide slowly drill the new hole with the 9mm bit. Use plenty of WD40 and blow out the shavings often. I wrapped black tape around the drill bit for a depth of 1".

Check often. You will see this when you are close:

You need to make sure you go deep enough to remove that ring of old threads in there.

When you punch through you will hear it. It makes a different sound and feel. This is what you want to see, a nice smooth surface:

Blow it all out, hose it down with brake cleaner.

Slowly start cutting new threads with the starting tap. Go in a few turns, and back out 1 turn. Do this till you bottom out.

Remove and blow out with compressed air.

Lubricate and switch to the bottoming tap. Run it in till you feel resistance and cut the last few threads.

Remove the tap, blow it all out, hose it down with brake cleaner.

Test fit the bolt, make sure it snugs all the way down and is flush! Art stated the surface the bolt compresses needs to be perfectly flat and clean! Make sure you do this. Art said you should also put a slight bevel on the bolt hole opening in the flywheel to give the bolt more surface area to seat against. I followed this advice. Just use a slightly bigger drill bit and give it a quick spin around each bolt hole WITHOUT drilling into them. You just want a slight beveled edge.

Insert the new bolts using ARP's intructions and torque to 70ft-lbs. I guarantee you will never deal with loose bolts again.

Wash, repeat 7 more times.

***** Note this only works with fbody flywheel. You will need bolts 1/4" longer if you use an aluminum flywheel.*******

------------------

2009 G8 GT Kook's 1 3/4 LT's, Kooks catted Xpipe, Magnaflow axleback, Vararam CAI, HSRK, HPTuners, Atari gauges

1988 Fiero GT L67, GT4067S, w2a, F23. 460whp/475lbft @ the wheels on low boost.

1987 Fiero GT 3.4TDC Road Racer.

ƒ13r0'$ rµ£3[This message has been edited by BV MotorSports (edited 02-02-2016).]

|

|

|

Darth Fiero

|

JAN 26, 08:46 PM

|

|

How much material is left between the threads and the OD edge of the crankshaft after enlarging those holes?

Got any pictures?

|

|

|

BV MotorSports

|

JAN 26, 08:47 PM

|

|

|

Stand by, I'll take a pic of the old crank I tested it out on.

|

|

|

BV MotorSports

|

JAN 26, 08:54 PM

|

|

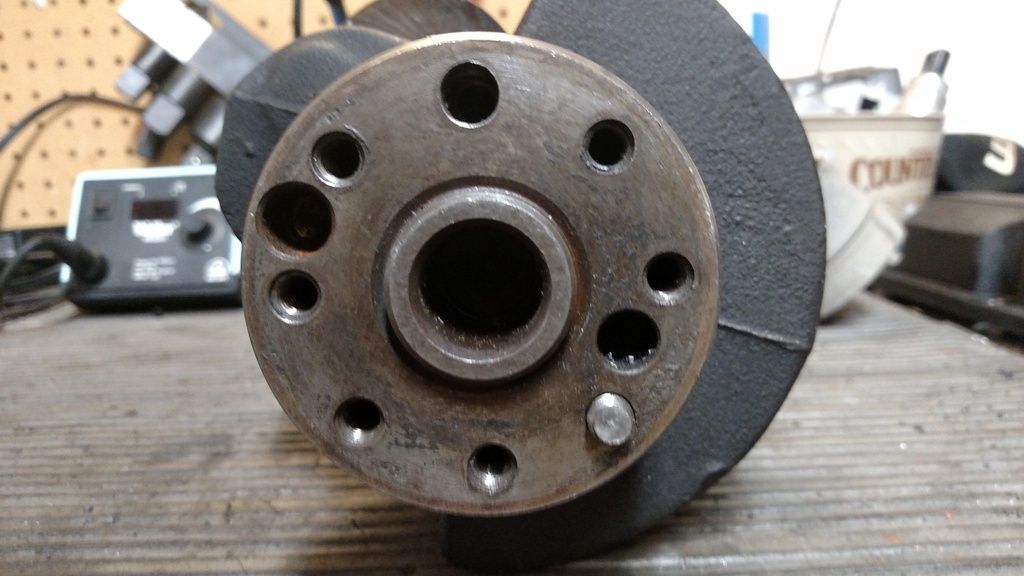

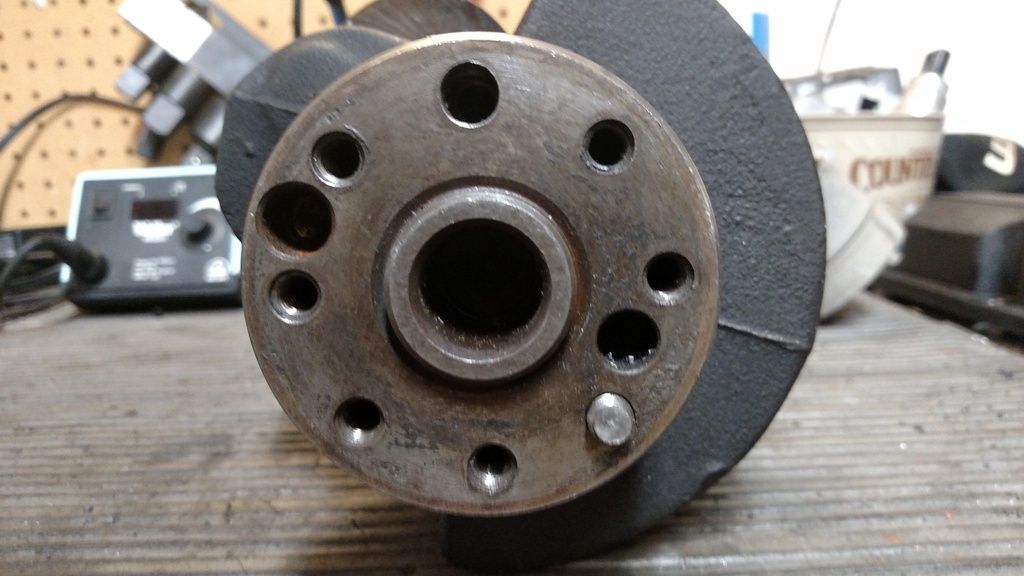

Top bolt hole is now 10mm. All others are 5/16ths.

|

|

|

Darth Fiero

|

JAN 26, 09:02 PM

|

|

| quote | Originally posted by BV MotorSports:

Top bolt hole is now 10mm. All others are 5/16ths.

|

|

Looks like you might run into a problem with those two holes that are right next to the existing large hole. I would be interested in seeing a picture of the finished product (all holes drilled and tapped to 10mm).

|

|

|

BV MotorSports

|

JAN 26, 09:09 PM

|

|

I have 460whp/475ft-lbs which is way more than your average 3800 swap. I am up to 500 miles (way past where the other bolts have failed or backed out), I'd say its good to go. Notice the broken bolt in the test crank? Failed with less than 100 miles. Thats an ARP cam bolt BTW.

Here ya go (from above engine):

[This message has been edited by BV MotorSports (edited 01-26-2016).]

|

|

|

Slammed

|

JAN 26, 09:44 PM

|

|

|

I just went to Fastenal and got 12.9 hex bolts and put blue loctite on them. Is this a common issue, the backing out?

|

|

|

BV MotorSports

|

JAN 26, 10:01 PM

|

|

| quote | Originally posted by Slammed:

I just went to Fastenal and got 12.9 hex bolts and put blue loctite on them. Is this a common issue, the backing out? |

|

Very. The more power you have, the more likely that they will fail.

|

|

|

viperine

|

JAN 26, 10:35 PM

|

|

|

I've been pondering options like this for my upcoming 3800 swap, Hoping to achieve 350 hp without an intercooler. Question here is, why would ARP list torque with their lube for a flywheel application? Thread locker is standard here, isn't it? And I'm awfully surprised at the cost of $20 per bolt. Seems more like the price for the whole bag.

|

|

|

BV MotorSports

|

JAN 26, 10:45 PM

|

|

| quote | Originally posted by viperine:

I've been pondering options like this for my upcoming 3800 swap, Hoping to achieve 350 hp without an intercooler. Question here is, why would ARP list torque with their lube for a flywheel application? Thread locker is standard here, isn't it? And I'm awfully surprised at the cost of $20 per bolt. Seems more like the price for the whole bag. |

|

Call Alex @ ARP and give him the p/n. Its $21 per bolt for their "custom age material" bolts. Also notice the quantity of 40. The more you buy, the cheaper they are. Only buying 8 will be more expensive per bolt.

Guys, I have been working on this issue for 8 months. I am telling you, 24 ft-lbs for hardware store & ARP cam bolts is not going to cut it on a 3800 with a manual trans. 34ft-lbs with the $21 a piece bolts isnt going to work either. 70 ft-lbs is a install it and forget it solution.

Edit, the right bolt, for the right application, with the correct TQ usually doesn't require thread lock.[This message has been edited by BV MotorSports (edited 01-26-2016).]

|

|

|

|