|

| So... What about an LT1 based 302? (Page 1/3) |

|

Raydar

|

SEP 11, 09:16 PM

|

|

I've been thinking about this for a while. (Not like I'm going to run out and do it, or anything.  ) )

The Gen II smallblock, aka LT1, LT4, etc, uses a 4" bore block.

There is a 4.3 liter engine based upon the same architecture, that uses a 3" stroke.

Why not an LT1 or... even an LT4 based 302, utilizing that architecture?

Yeah... I know about the LS engines - especially the LS4 -, and I know about the "gotchas" associated with the LT1 Optispark, but it just seems like it might be a cool, unique thing to do.

Moving the power band up in the rev range will help to save transaxles, and the high revving nature of a 302 would seem to suit the Fiero's character better.

This is all based upon the premise that everything in the engine is built to support the high RPMs that would be expected.

Anyone?

|

|

|

La fiera

|

SEP 11, 09:55 PM

|

|

Well, at Hi RPMs balancing the rotating assembly is king. 2oz off and you'll rev it to 8200rpm and something is goung kaboom.

That 2oz at 1200rpms will grow exponentially at 8200rpms. I've built a couple of LT1s and they were monsters, but I made sure that every item complemented the other.

The higher they would rev, the more money you'll spend in parts and machine shop fees because everyting has to be balanced.

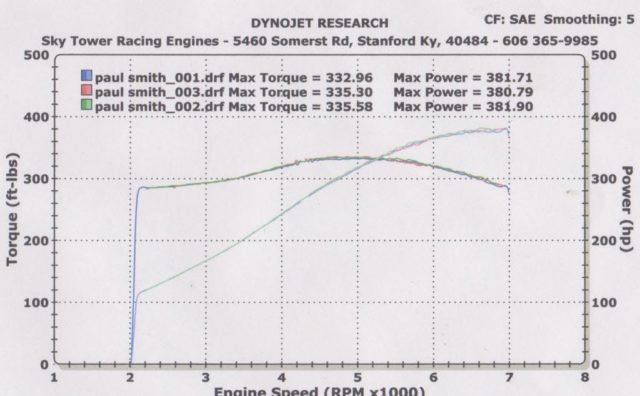

431WHP and 497WTQ

And that is with the trans, driveshaft and diff of an Fbody car. In a Fiero this engine would have at least another 50WHP/WTQ

Look at the dyno above, I did the heads, designed the cam according to the rotating assembly geometry. This one went from a 350 LT1 to a 377 strocker.

The rod ratio changed, so I had to make the rest of the package to take advantage of the lower rod ratio. Lower rod ratio increases piston speed.

The increase in piston speed draws in and air/fuel mixture faster than a higher ratio engine and from half way the exhaust stroke to half way the intake is a lot faster than a higher rod ratio engine. This means acceleration is instant. In a Fiero, this 377 strocker would break axles left and right!

|

|

|

Raydar

|

SEP 11, 10:19 PM

|

|

| quote | Originally posted by La fiera:

...

In a Fiero, this 377 strocker would break axles left and right! |

|

I'm sure of it.

Thanks very much for your response. And yeah... all of that gearbox and axle shattering torque is precisely why I was thinking a lower torque, but high revving engine. (Where did the original 302 redline? 7K? 7200?)

Again... I recognize there are much more realistic, less expensive, and more easily accomplished swaps than this. Just a bit of "off the beaten path" thinking. (The sound would have to be amazing.)[This message has been edited by Raydar (edited 09-11-2020).]

|

|

|

OH10fiero

|

SEP 11, 11:10 PM

|

|

|

I read an article at one time that there is a way around the opti-spark and to use the 1 coil per plug type set up. not sure which hot rodding magazine i read that in but should not be hard to find if you seriously consider the LT1. Want to say Car Craft because what I do remember was a parts list of things to grab while at a junk yard for the set up and that is something that would be on par for them.

|

|

|

La fiera

|

SEP 11, 11:25 PM

|

|

|

The best SBC for the Fiero is the 283. High revving and low torque, the perfect match!

|

|

|

MarkS

|

SEP 12, 07:35 AM

|

|

Years ago when considering an Archie kit, was thinking a 302 SBC with modern aluminum heads would be a fun conversion. With a velocity stack sticking through the deck right behind your ears; wonderful sound I bet.  Kinda where your going. Kinda where your going.

|

|

|

olejoedad

|

SEP 12, 07:49 AM

|

|

If you can do it with an aluminum block....fine.

Why mess up the balance of the car with a big chunk of cast iron in the arse end?

|

|

|

fieroguru

|

SEP 12, 08:20 AM

|

|

Over the years building a later model 302 using the 4.3 L99 crank and rods has been discussed. I even looked at it a couple of times. The reality is you no longer need a 3" stroke to run 7000 rpm and doing anything with a SBC platform will take a lot more work and money that starting with the LS platform. 7000 RPM and 400+ fwhp is literally a camshaft swap with the 4.8 and 5.3 LS engines... no porting, polishing or other custom work needed.

Fore example, here is my LS4 dyno. The goal was a high rpm power band using as many stock GM LS based parts w/o any custom porting or other optimizing work. Only aftermarket parts were the camshaft, pushrods, and springs, the rest of the engine wasn't even opened up and I even kept the DOD lifters! The combo had a 5000 rpm power band with 80% of peak torque available. The overall toque level was a good match with the F40 torque rating (only about 25% higher than the GM rating), but still plenty to shred the 285 rear tires at will, and put 55K miles with the combo w/o breaking anything. Yes, there was a lot of power left on the table, but the goal was to demonstrate how good the stock GM LS parts were and the power potential from a super simple setup.

|

|

|

Blacktree

|

SEP 12, 11:21 AM

|

|

| quote | Originally posted by Raydar:

I've been thinking about this for a while. (Not like I'm going to run out and do it, or anything.  ) )

The Gen II smallblock, aka LT1, LT4, etc, uses a 4" bore block.

There is a 4.3 liter engine based upon the same architecture, that uses a 3" stroke. |

|

OK, I'm gonna be "that guy".

Why not just use a smaller engine? For example, the 4.3 or 3800 V6 would fit the bill nicely. Swap in a more lively camshaft, and you're done.

Another alternative would be a small-displacement V8, like the 4.0 version of the Northstar used in the Olds Aurora. The downside to that would be lack of aftermarket support.

Anyway, there's a pervasive myth that destroke = high RPM. Destroking an engine, in and of itself, will not necessarily increase the usable RPM range of an engine. The maximum RPM of an engine is often limited by the valvetrain. If the valves float at 6500 RPM, then no amount of destroking will change that. So if you destroke the engine and leave a stock-ish valvetrain in it, then you have the worst of both worlds: weak low-end torque, and it can't rev high enough to make decent power.

And as Rei mentioned, at high RPM engine balancing becomes critical. Plus you need to worry about things like the harmonic balancer or the flywheel ring gear flying apart. It's a whole new ball-game.[This message has been edited by Blacktree (edited 09-14-2020).]

|

|

|

pmbrunelle

|

SEP 12, 12:16 PM

|

|

| quote | [B]Originally posted by Raydar:[/B

Moving the power band up in the rev range will help to save transaxles, and the high revving nature of a 302 would seem to suit the Fiero's character better. |

|

Nowadays with throttle by wire (some aftermarket ECUs can control this), you can just open the throttle less in 1st gear. Also you can open the throttle more slowly than the pedal under the driver's foot, reducing the drivetrain jolt.

A turbo engine does this naturally; the lag slows the response; it's like a way of mechanically pressing the gas pedal slowly to the floor.

None of these ideas are good for response / controllability, but they could help a transmission stay alive.

The throttle-by-wire is probably better for this; you can (with a laptop) tune how fast or slow the throttle opens, allowing you to find the response vs. transmission niceness compromise you want. With a turbo, you're kind of stuck without changing the hardware.

|

|

|

|