|

| Ms3x to fiero vss (Page 1/1) |

|

Eltsyrk

|

SEP 30, 09:01 PM

|

|

|

I am swapping my ecu over to a ms3x and have all but the fuel fan and vss wired in but im stumped at this point iv been reading that possibly just connecting the yellow would work but i want to tap into the knowledge of the forums before i do that any input is much appreciated thank you btw im not running stock gauges iv swap completly over to autometer sport comps ------------------

1986 fiero se 2.8 v6 4 speed

|

|

|

pmbrunelle

|

SEP 30, 09:37 PM

|

|

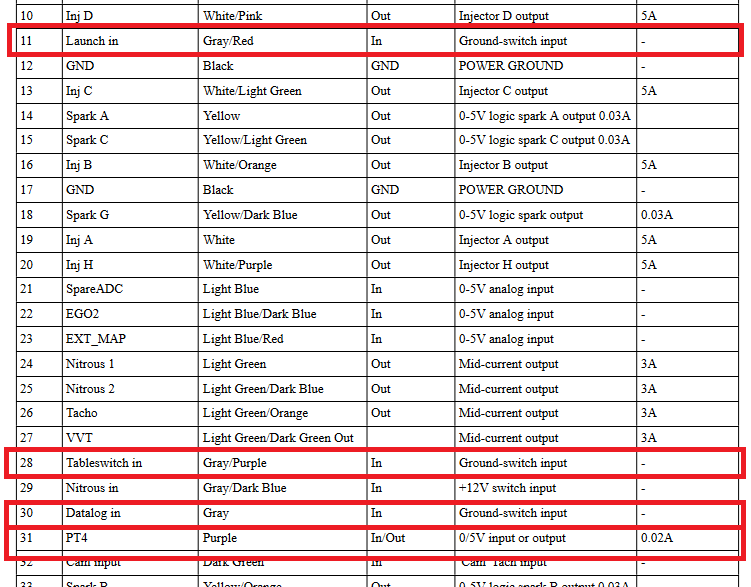

These are the inputs that can be used to read a speed sensor:

http://www.msextra.com/doc/...Hardware-1.5-42.html

Input description:

http://www.msextra.com/doc/...Hardware-1.5-20.html

So depending on the input you choose for the speed sensor, it will be either a Ground-switch input or a 0/5V input or output.

Annotated screenshot:

Do not blindly connect the yellow wire to any of those inputs as-is! You will fry something in your MS3X if you do that. I haven't measured it, but I assume that the voltage on the yellow wire can reach into the tens of volts, if not more. You will need to supply a speed signal that is compatible with either a Ground-switch input or a 0/5V input or output.

Since the yellow wire is neither of these, the signal should be converted into a form that can be safely read by the MS3X.

On my Fiero, I used the stock buffer board, which has an open-collector output to the ECM. I connected that to the Tableswitch in input, and the VSS reading worked as it was supposed to. I tested it up to 100 mph.

If you want the VSS but don't have the stock buffer board, you'll need to implement some sort of "translator".

I don't find the VSS to be a terribly essential input for MS3. For the moment, its only function on my car is to turn down the idle RPM when the car is fully stopped. It's also handy in datalogs to see what's happening.

At some later time, I may use the VSS to recognize when the car is stopped, to implement a different rev limiter when the car is at the starting line of a drag race, the idea being to build boost off the line.

Also, with the RPM/VSS ratio, the current gear can be identified. Then, you can set different boost pressure targets per gear.

Was there any specific feature you wanted to use that required a VSS connection?

|

|

|

Eltsyrk

|

OCT 01, 11:42 AM

|

|

I plan on using the signal to run my speedo and shift light but after reading the autometer electric speedometer instructions it seems more feasible to run the yellow hi output wire to the gauge then the guage will produce a +5v dc square wave that can go to the ecm

Mean while the low wire will be grounded out

My plan for running to the ecm allows me to have a shift light not really necessary but i thought since i have the car torn down mine as well do all my plans before putting it back together

Would you by chance Know the size of the threads for the fuel rails 7th fuel injector i have to cover that on my build

------------------

1986 fiero se 2.8 v6 4 speed

|

|

|

pmbrunelle

|

OCT 01, 12:23 PM

|

|

| quote | Originally posted by Eltsyrk:

I plan on using the signal to run my speedo and shift light but after reading the autometer electric speedometer instructions it seems more feasible to run the yellow hi output wire to the gauge then the guage will produce a +5v dc square wave that can go to the ecm

Mean while the low wire will be grounded out

|

|

Sounds like a good plan.

| quote | Originally posted by Eltsyrk:

My plan for running to the ecm allows me to have a shift light not really necessary but i thought since i have the car torn down mine as well do all my plans before putting it back together

|

|

Yup, it's easier to do it once the way you want it, vs. reopening the wiring every time you want to add something.

For information, I'm using a Mid-current output on the MS3X to drive the check engine light (194 bulb) in the Fiero cluster, so I think a Mid-current output should work well for a shift lamp.

| quote | Originally posted by Eltsyrk:

Would you by chance Know the size of the threads for the fuel rails 7th fuel injector i have to cover that on my build

|

|

I don't remember the thread size off-hand. I used an oil drain plug (with its copper washer) to plug the hole on the fuel rail. I got it from the HELP! section of Canadian Tire.

Initially, I kept the 7th injector to plug the hole in the lower intake manifold. I drilled out the middle of the 7th injector, removed the plastic bits, and welded the centre shut. I then faced the visible surface smooth and flat, then painted the piece black. The stock O-ring sealed the piece to the intake manifold as always.

Later on, I decided to drill and tap the CSI hole in the intake to 3/8" NPT. With some Teflon tape, and an Allen-head pipe plug, I was able to plug the hole.

|

|

|

|