|

| Help with a LS4/F23 swap (Page 1/5) |

|

Rotmilky

|

DEC 06, 04:40 PM

|

|

My first post here. I could use some help to keep my project moving forward at a steady rate...

A bit of background on the project. I've got 2 daughters who are 13 and 16. Due to Covid, the public school is shut down and they are doing 100% online learning. It sucks for all of us. They only go to school for 1/2 days and honestly aren't learning much of anything. Since August, school would end at noon and they'd sit around watching TV or playing on their phones.

I'd ask them if they'd finished their homework. "Already did it". Did you clean your room. "Already did it". Did you get some exercise. "Went for a run an hour ago". So, I'd say they needed to find something to do besides play on their phone. After 3 months of that, I had exhausted just about every activity I could think of. So...I needed to create some kind of long term activity for the kids to keep them busy an off their phone. After a bit of thought, I decided fixing a broken down car would be a good educational experience. So, I created what I'm calling "Grease Monkey 101" and am forcing the girls to do 2 hours of car repair a day.

I didn't have a car that I trusted them to work on, so I started looking for a cheap car. It needed to be dirt cheap and not running. That way if they tore it up, it wouldn't be a big deal. I didn't have a particular car in mind...just cheap and something I thought would be fun to drive once it ran. Looking in Facebook marketplace, I found a '84 Fiero for $200. Sad interior, caked in dust, a few rats nest in the engine bay. Perfect!

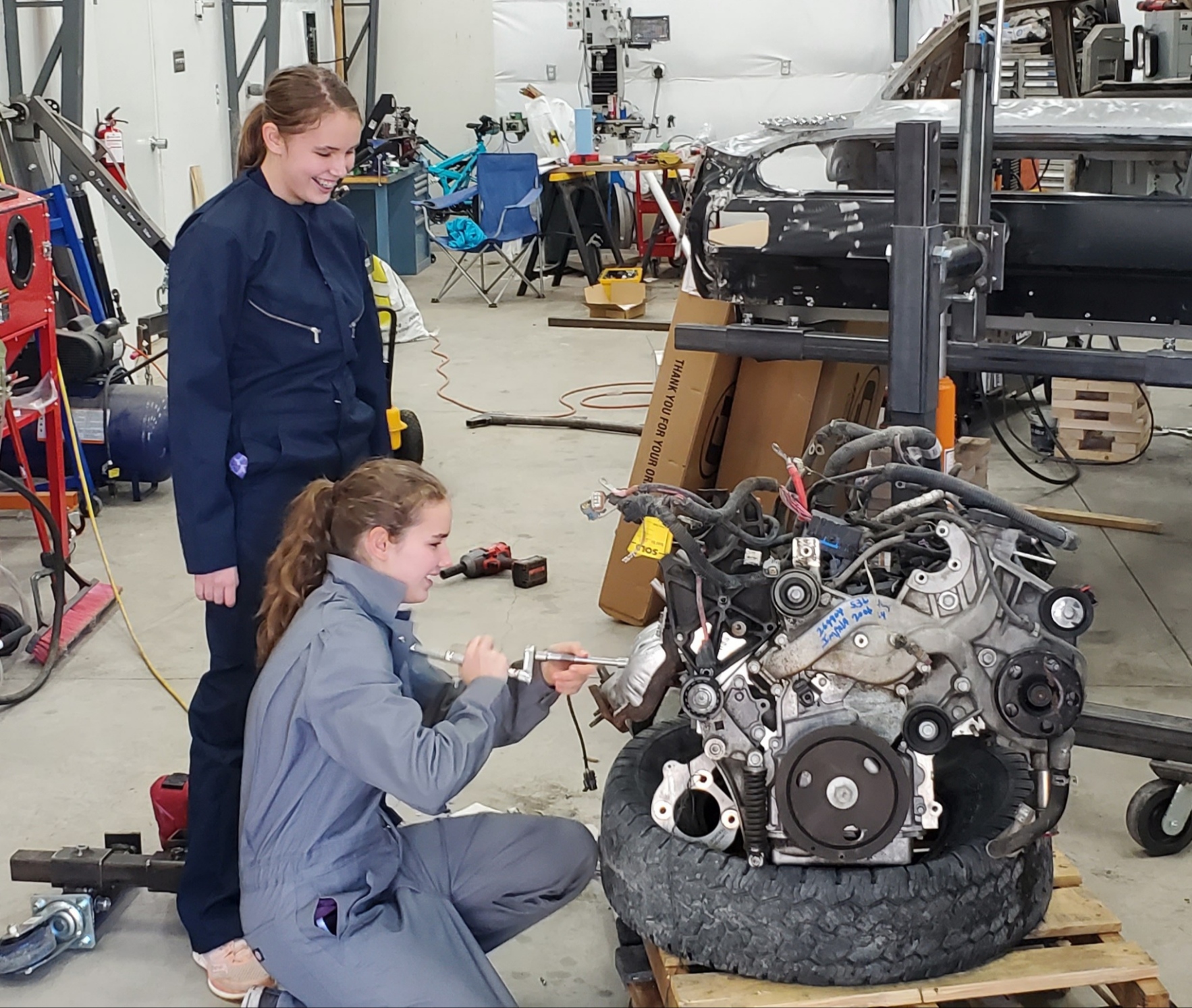

It was supposedly 'running when parked'. I knew that meant there was a high likelihood that there would be major mechanical problem, but I hoped we'd be able to get away with an engine rebuild and leave the care pretty much stock. I knew that there was a substantial amount of information on engine swaps for the Fiero and decided if the engine couldn't be used, well installing a different motor would be an educational experience for my newly enrolled Grease Monkeys. And here they are on the first day, complete in their new Carhart overalls beginning to determine what was wrong with the car

|

|

|

Rotmilky

|

DEC 06, 04:44 PM

|

|

We jacked the car up, put it on jackstands and then put a socket on the crankshaft. It wouldn't budge. Well, that wasn't the best news for getting it running with minimal work. We drained the oil pan and the first 10 seconds of fluid to come out was coolant. Ooh, definately going to be more involved. We did get to discuss why having green fluid come out of the oil pan was not good...so it was still educational.

But more work was needed to figure out what was wrong. Over the course of a week, we managed to pull the exhaust manifold, the intake manifold, and then the head. Now the problem was apparent.

Another educational experience for the girls. "Umm, dad, should there be holes in the middle of the pistons?". Keep in mind they didn't know what a piston was when I drug the car home...so they weren't entirely sure if those were supposed to be there. They did recognize the fractured edge probably was an issue.

We set about pulling the motor. I made them do it all with the exception of periodically having to help loosen a particularly stuck bolt. I'm basically fetch tools and sometimes help them figure out how to reach difficult spots with suggestsions like using an extension or a crow's foot, etc.

It took most of a week to get all everything off and get the motor out, but they managed to get it done.

Now, I needed to source a replacement motor and transmission. Since I have teen age girls doing the bulk of the work, there is a very high probability that this project completely fails, so I'm doing this as cheaply as possible. That way, if school starts back up and they don't want to finish the project, I'm fine with hauling it to the scrap yard. To keep it cheap, I'm getting what I can find locally at junkyards. Plus I consider it extra credit for Grease Monkey 101 when the kids spend the day at the junkyard with me pulling stuff.

I managed to find a LS4 out of a '06 Impala that was largely complete...but missing intake manifold and the computer. It was cheap (like $200) so we pulled it. It was in decent shape but had some light rust on the inside of the cylinder walls. I think I'll have the girls pull the pistons, hone the cylinders with one of those dingleberry hones and install a new set of ring, do a DoD delete. Maybe put on a LS3 manifold and timing cover. Dunno exactly...I'll figure that out if we make enough progress to warrant it.

In the transmission department, I wanted to try to put in a F40...but just couldn't seem to find one in the local junkyards with the GM metric pattern. We did manage to find copious numbers of F23s. So, we yanked one from a 2002 Sunfire. We also weren't entirely sure what parts would be needed for the swap, so we also took the clutch/flywheel, axles, shift cables and shifters. I didn't think we needed that, but didn't want to come back for them if we did. The girls really don't like spending the day at the junkyard...so I try to minimize the time there. Anyway, here's the F23 sittin in the parts washer while we try to remove all the caked on gunk

At the moment, we're still getting the original 4 cylinder off the engine cradle and separated from the transmission. That'll probably keep the kids busy for the next week.

That basically brings the story to present day. I'm hoping I can use this thread and the many contributors on this board to keep the project moving along. The kids are having a lot of fun, but we haven't been bogged down by needing to figure out what we need to fab. Since this is an educational project, I plan to have them fab as much as we can. I have a lathe and a mill, plus welders, grinders and such. I figure it's better to teach them how to use these things than it is to buy ready made mounts, etc.

It's a ton of work on my part to get ready for them to do 2 hours of work on the car 5 days a week. I plan on asking loads of questions -- to keep the project moving and keep the kids engaged. I worry that if it bogs down too long, they'll lose interest.[This message has been edited by Rotmilky (edited 12-06-2020).]

|

|

|

fieroguru

|

DEC 06, 06:03 PM

|

|

|

|

Raydar

|

DEC 06, 07:08 PM

|

|

As a telecom geek, I have occasionally been tasked with the job of training new techs to do what I do. (Job security is NOT an issue. All I'm going to say about that.)

It's quite the daunting task, as it's generally much easier to just do it myself, than it is to tell/show someone else how to do it.

Having said all that... I applaud your efforts to teach your young ladies to do this stuff. Even if they eventually lose interest, it's still something that they can use, later on in life, if they can retain the logic behind what they were doing.

I wish you luck with your project.

|

|

|

Rotmilky

|

DEC 06, 08:11 PM

|

|

Thanks for the reply. I've been digging through this post for the past few weeks trying to absorb all the inforrmation. I'm hoping to use your threads for a fair amount of the fab information. That said, my lathe and mill are smaller than yours...and I'm at best a hack machinist...who will be attempting to teach my teenage daughters to do the work. Lots of places for this to go wrong. But if we end up with a running car with ugly parts at the end, it'll be a success.

|

|

|

Rickady88GT

|

DEC 06, 08:14 PM

|

|

|

|

pmbrunelle

|

DEC 06, 09:22 PM

|

|

| quote | Originally posted by Rotmilky:

But if we end up with a running car with ugly parts at the end, it'll be a success. |

|

Eventually, the girls might even fight over who's turn it is to drive the Fiero!

Sounds like you've turned yourself into a home-school teacher. A lot of work for you, but teaching your kids is worth it.

|

|

|

Shho13

|

DEC 06, 11:40 PM

|

|

Welcome to the forum, glad you and your two daughters are here!

For what it's worth, an LS swap is definately not one of the more straightforward swaps to do... but the reward is definately worth the trouble! Also will be some differences in wiring since you're working with an 84.

I would reccommend reaching out to Gary Pickardt of Pickardt Performance on Facebook for any help you may need with fabbing up and sourcing parts and other stuff for your swap. He is a great guy and his work is phenominal. He's going to be doing the LS4 swap in my 88.

Good luck with the swap! We will all be around, don't hesitate to ask questions and such! 🙂

------------------

"Discord"

Red 1988 GT under restoration!

Let's Go Mets!

( ͡° ͜ʖ ͡°)[This message has been edited by Shho13 (edited 12-06-2020).]

|

|

|

Rotmilky

|

DEC 08, 11:45 AM

|

|

Thanks for the words of encouragement and offers help. I'll probably need it to keep this project moving forward. I've spent a lot of time over the past week trying to plan out the swap and am running into a slight bit of confusion.

Almost all the information I find is for the LS4/F40. Since I have the F23, I'm not sure how much of the F40 information applies.

I *think* I sorted the starter. Fieroguru's bracket looks like it will work and I've seen at least one thread where it was used. So I'm going to do that.

On the clutch/flywheel, I'm not finding tons of information for the LS4/F23 specifically. One thread used a reworked Northstar combination (Grin Reaper Redux thread) because he started out with a Northstar. I've seen some info that suggests the 2002 clutch/flywheel off the Sunfire F23 that I pulled *should* work.

Anyone know what will/won't work for clutches and flywheels on the F23? Can I just assume the F40 information is largely applicable to the F23?[This message has been edited by Rotmilky (edited 12-09-2020).]

|

|

|

Rotmilky

|

DEC 09, 04:31 PM

|

|

After lots of digging, it seems like the LS4/F23 is not a common swap. Poop! Makes it harder to figure out what it takes to mate them.

| quote | Originally posted by Rotmilky:

I've seen some info that suggests the 2002 clutch/flywheel off the Sunfire F23 that I pulled *should* work.

|

|

After looking a bit closer, the F23 flywheel is certainly not a bolt on solution. The LS4 and F23 both have 142 tooth ring gears and both have 6 bolts holding them to the crankshaft. However, the bolt circle diameters are different (3.1" for LS4 vs 2.35" for F23) and the center hole diameters of the flexplate/flywheel are different (1.7" for LS4 vs 1.25" for the F23) So. the flywheel off the Sunfire is not a direct bolt on and I think if I tried to enlargen the center hole of the F23, I would get it awfully close to the bolt holes.

Would it be possible to weld the F23 flywheel holes shut, redrill it for the LS4 pattern and then make the center hole 1.7" in diameter on a lathe? My local machine shop should should be able to do that, I would think and seems like it'd be pretty cheap. The outside of the F23 flywheel looks like it'd sit 0.830" off the LS4 flange. Currently the outside of the ring gear on the flex plate it 0.835". Basically the F23 flywheel would occupy the same space as the current flexplate/ring gear. A stage 2 clutch/pressure plate rated to ~300 ft/lbs for this is about $550.

If that doesn't work, I've also been looking into putting a LS1 flywheel on there. Based on a post by Fieroguru, Flywheel thickness, he mentions that the LS1 flywheel will protrude to ~0.820", which is basically where the current flexplate/ring gear sits. It'd need to be turned down to fit the 142 tooth gear, but it would have the correct bolt pattern to bolt to the flywheel. Also something my local machine shop would be able to handle. Then I assume the ring gear is interference fit onto the outside of the newly reduced flywheel. Then I suppose a couple of tack welds keep it from slipping? The downside to this approach is the cost of getting a LS flywheel at $100-130. I still haven't figured out what clutch everyone is using for this approach.

Finally, I think I can call Spec and have them just build it for me. Does anyone know the cost for that?

Once I get that sorted, is there anything I'm missing that will prevent me from assembling a functional transmission/clutch to the LS4?[This message has been edited by Rotmilky (edited 12-09-2020).]

|

|

|

|