|

| Studs (Page 1/2) |

|

La fiera

|

DEC 13, 01:29 PM

|

|

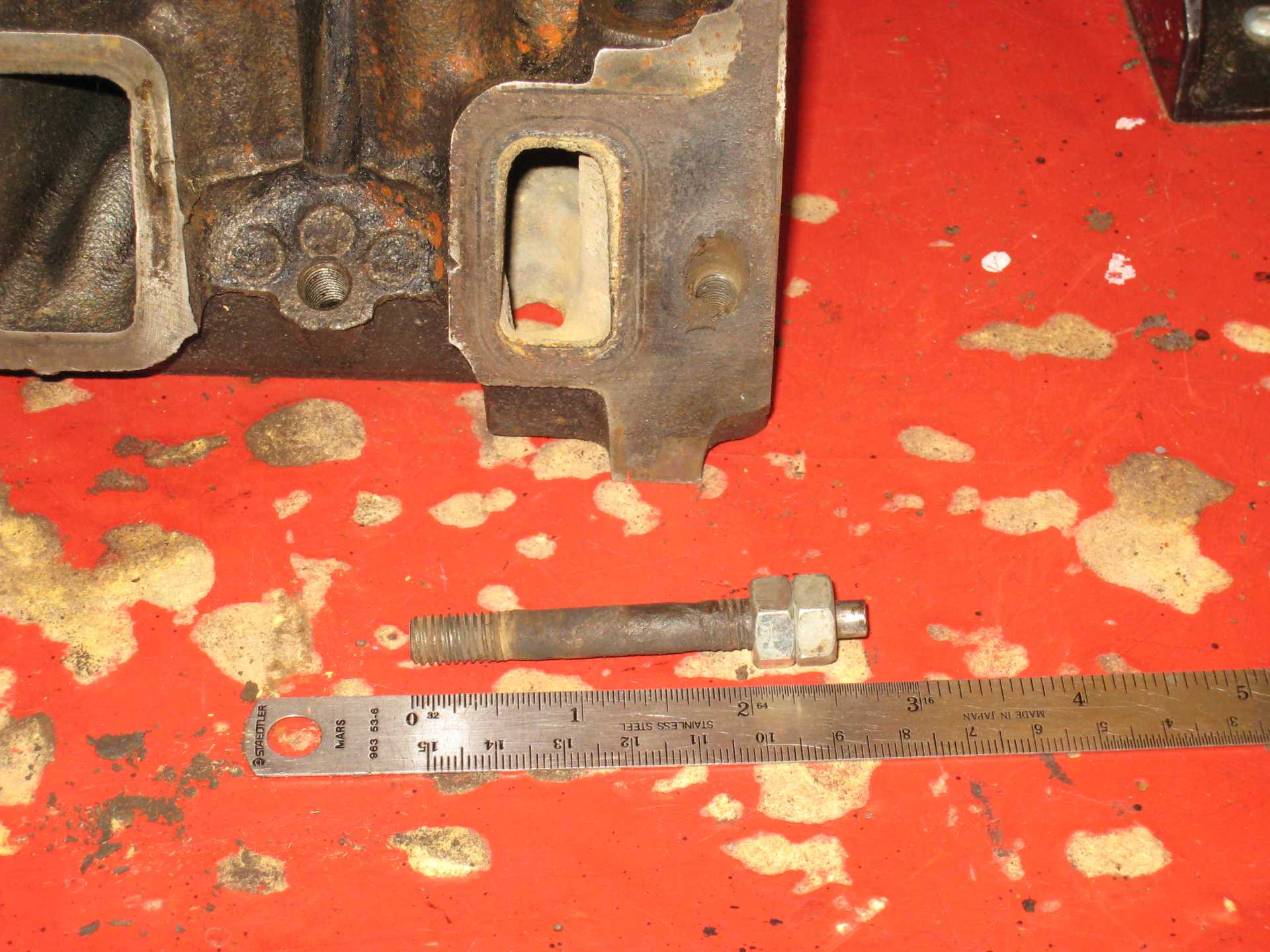

Does anybody know where can I get these studs?

Thanks

Rei

|

|

|

pmbrunelle

|

DEC 13, 01:37 PM

|

|

Summit sells ARP studs in the M8x1.25 thread size:

ht tps://www.summitracing.co...g&keyword=ARP&kr=ARP

I don't know off-hand how long they need to be; measure and let us know.

If you don't care about shiny, and "good used" is good enough for you, I have a spare head with two studs I can send to you.[This message has been edited by pmbrunelle (edited 12-13-2020).]

|

|

|

La fiera

|

DEC 13, 07:04 PM

|

|

| quote | Originally posted by pmbrunelle:

If you don't care about shiny, and "good used" is good enough for you, I have a spare head with two studs I can send to you.

|

|

I don't care about shiny! I'd really appreciate it, I only need one.

|

|

|

pmbrunelle

|

DEC 13, 09:37 PM

|

|

I used two nuts torqued against each other to be able to turn the stud.

This stud is longer than the available ARP studs (max 2.25") , so the ARP studs would not have worked.

This stud doesn't have the external Torx like yours do, so you can drive it in with the double-nut method.

When do you need the stud?

PM me your address (I didn't write it down somewhere convenient).

********************************************************************************

For anyone looking for a source of new studs, it looks like Dorman PN 675-337 would work. It's a package of 10 studs. I have not tried this.[This message has been edited by pmbrunelle (edited 12-13-2020).]

|

|

|

La fiera

|

DEC 14, 07:17 PM

|

|

|

Thanks Patrick! I ordered some locally. I appreciate your promt response!

|

|

|

Raydar

|

DEC 15, 06:24 PM

|

|

|

Be careful reusing those. I was installing a lower intake, and broke one. It stretched until it broke. Never reached torque spec.

|

|

|

pmbrunelle

|

DEC 15, 08:03 PM

|

|

I do not rely too heavily on a torque wrench when I work on my cars. Disclaimer: I am not a professional mechanic.

If you notice that you're turning the bolt a lot without a corresponding rise in torque, that means you're not far from breakage, so stop. The "calibrated arm" and experience will tell you this.

People sometimes put too much value in torque values, but torque is not the goal. The real objective is to stretch the bolt a certain amount; torquing a bolt is a hit-or-miss method to obtain the desired stretch.

I have a project now, and (well one tool I have) to determine the bolt torque to be used by the factory, is that I tighten some assemblies with my trusted arm and feeling, and then I measure how tight I tightened the bolt with a torque wrench.

Trust your feeling! And if you don't have it, practice! (some bolts may be broken along the way)[This message has been edited by pmbrunelle (edited 12-15-2020).]

|

|

|

Frenchrafe

|

DEC 16, 03:13 AM

|

|

As was said above, it's the feeling that helps the most when doing up bolts!

Personnally, I only use the torquewrench on cylinder head bolts, drive shaft nuts, wheel nuts on alloy wheels, and end cap bolts.

The rest is done with feeling! (And locktite on those pesky flywheel bolts that break even when torqued to spec!)

I've been repairing cars for the last 40 years and I broke my share of bolts in the first couple of years. Afterwards, I became a little better !

Regards,

Rafe

------------------

"Turbo Slug" - '87 Fiero GT. 3800 turbo. Sticky tyres. Driven hard!

https://www.youtube.com/cha...1wZvWQlkYxTjivW_0XNg[This message has been edited by Frenchrafe (edited 12-16-2020).]

|

|

|

Raydar

|

DEC 16, 07:58 AM

|

|

| quote | Originally posted by pmbrunelle:

....

If you notice that you're turning the bolt a lot without a corresponding rise in torque, that means you're not far from breakage, so stop. The "calibrated arm" and experience will tell you this.

Trust your feeling! And if you don't have it, practice! (some bolts may be broken along the way)

|

|

I definitely noticed. But then I thought "naaaah". Wrong thought.

It surprised me, because they really weren't that tight anyway.

I have broken bolts before, but this was the first bolt I have "stretch broken".

|

|

|

La fiera

|

DEC 16, 07:10 PM

|

|

I went to my local fastener store and they hook me up with these supa dupa fasterner. Thanks Patrick for the help!

|

|

|

|