|

| 1984 2.5 Head bolts best pratice (Page 1/1) |

|

Indy-453

|

JAN 01, 12:39 AM

|

|

Hello,

I have a 2.5 Iron Duke and I am preparing to install a rebuilt head. What is best practice for installing these head bolts?

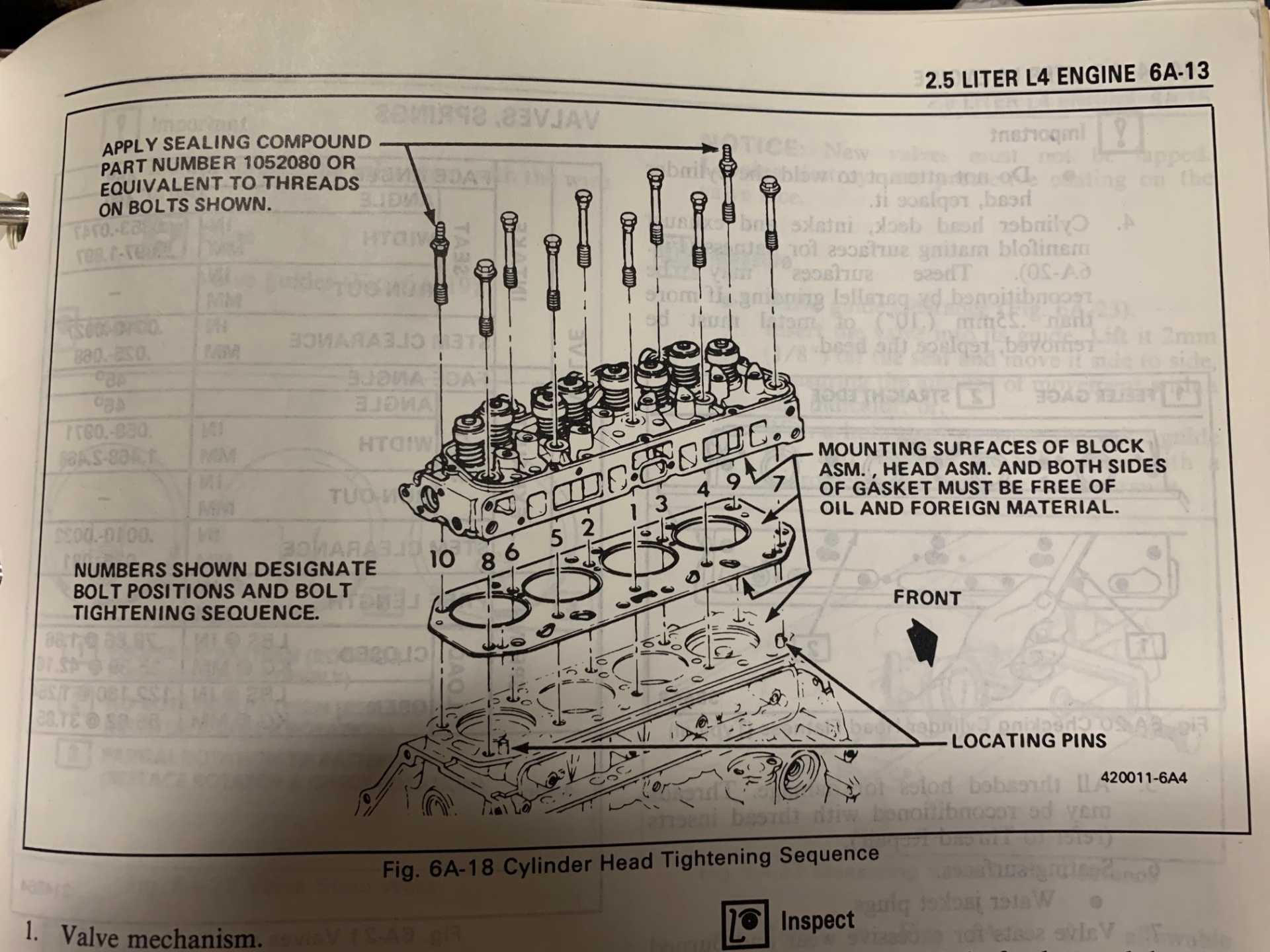

I have a copy of the 1984 Factory service manual, the diagram says to install the bolts with sealing compound on bolts 9 & 10, where as the numbered instructions are less clear and my reading of it is to use sealant on all threads.

When poking about with a metal wire, holes 1 - 8 seem like they are blind where as 9 and 10 do go into the water jacket.

Which would be the ideal method? I have ran a tap into all the holes to clean them out, and I am using new bolts.

|

|

|

pmbrunelle

|

JAN 01, 01:36 AM

|

|

Sealant can be viewed as a lubricant on the threads; the lubrication will reduce thread friction, and therefore influence the bolt stretch (and hence bolt load) resulting from the applied wrench torque.

I think that the bolt stretch will be more consistent with the same lubrication on all bolts, resulting in a more even clamping of the head onto the block.

Therefore, my recommendation is to apply sealant on all bolts.

|

|

|

Dennis LaGrua

|

JAN 01, 07:32 AM

|

|

The key to a successful head installation is to follow the sequence and torque the head bolts gradually 10 ft lbs at a time until the final torque has been reached. If any of the head bolts fit to the water jacket then a sealant must be used to prevent leaks.

------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE " [This message has been edited by Dennis LaGrua (edited 01-01-2021).]

|

|

|

theogre

|

JAN 01, 10:54 AM

|

|

FSM is likely Wrong listing all bolts to same torque.

Think TSB or later FSM has updated torque w/ different angles for sealer bolts but can't find it right now at have to leave soon so I'll look for it later if can today.

Install w/ sealer Only on two bolts that get wet w/ coolant.

------------------

Dr. Ian Malcolm: Yeah, but your scientists were so preoccupied with whether or not they could, they didn't stop to think if they should.

(Jurassic Park)

The Ogre's Fiero Cave

|

|

|

Blacktree

|

JAN 01, 12:36 PM

|

|

The service manual lists 2 different procedures, one for the '84-85 and another for the '86-88. They are as follows:

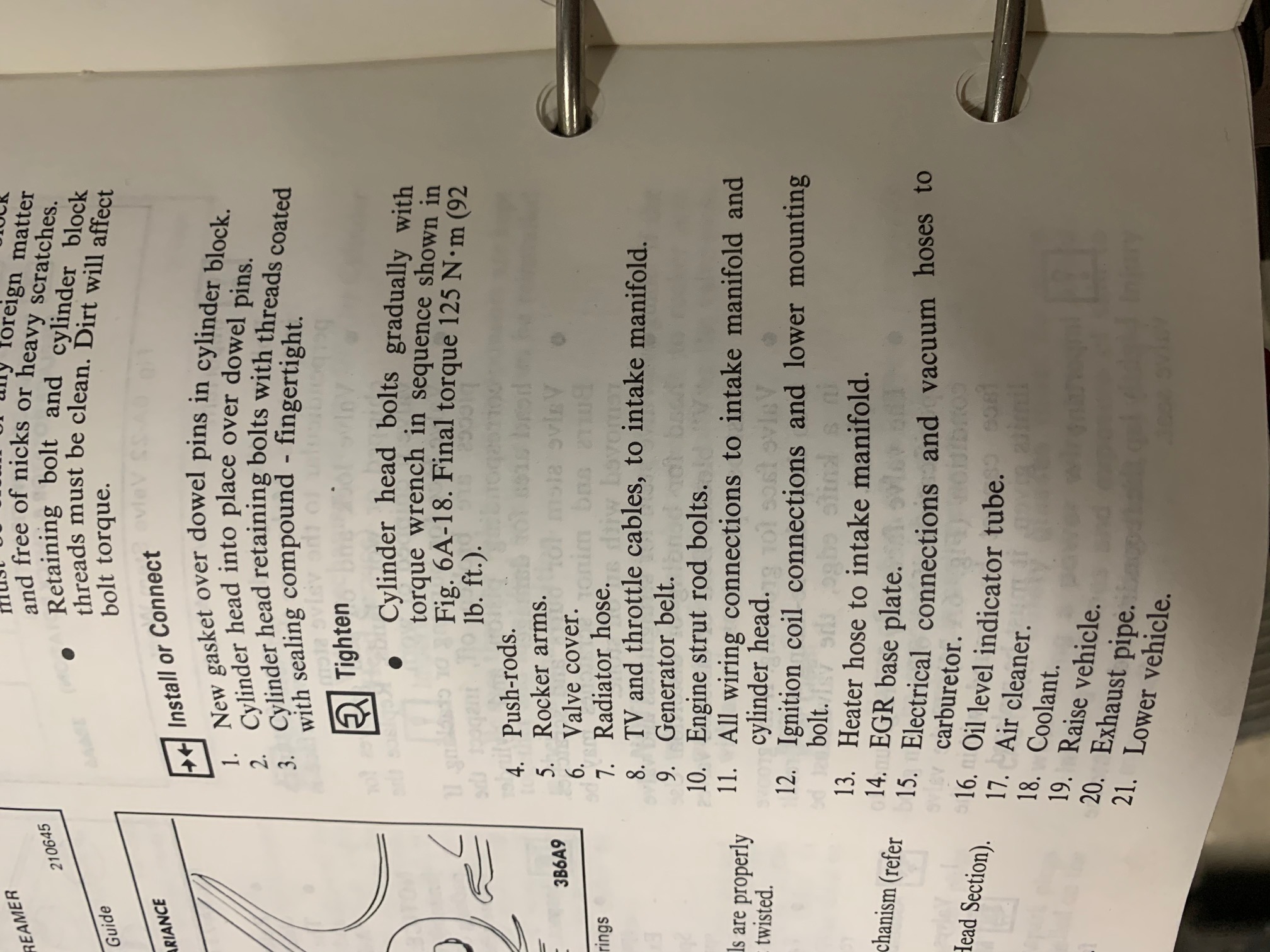

For '84-85 -- Install all head bolts finger-tight. Then torque them all to 92 ft-lb, in 3 stages.

For '86-88 -- Install all head bolts finger-tight. Then torque them all to 18 ft-lb. Next, torque all except #9 to 22 ft-lb (#9 is 29 ft-lb). And finally, turn all except #9 an additional 120 degrees (#9 is 90 degrees).

Both of these procedures specify applying sealant to bolts 9 & 10.

That said, I would tend to use the second procedure, especially with new head bolts. Because new head bolts will be designed to use the revised torque procedure.[This message has been edited by Blacktree (edited 01-01-2021).]

|

|

|

theogre

|

JAN 01, 04:29 PM

|

|

AllData gets notes etc Directly From GM and only list 2nd method w/ 120 and 90°

| quote | 17.Install new head gasket, then the cylinder head assembly, ensuring gasket and head are seated over dowel pins.

18. Coat threads of bolts 9 and 10, Fig. 2, with sealer, apply oil to remaining bolts and install all bolts finger tight.

19. Tighten bolts in 3 steps following sequence shown in Fig. 2. First torque all bolts to 18 ft. lbs. Second, torque all bolts except bolt No. 9 to 22 ft. lbs. Torque bolt No. 9 to 29 ft. lbs. Third, tighten all bolts except No. 9 an additional 120° (2 flats). Tighten bolt No. 9 an additional 90° (1/4 turn). |

|

⚠️ Warning: Never reused Duke head bolts. Many OE ones are weak and even break and often can't tell if bolts are OE or replacement anytime over 30+ years. (Not good idea for many other engines. Worse, Other engine have Torque To Yield and must be replace every time and often use same method torque to X ft/lb then Y°.)[This message has been edited by theogre (edited 01-01-2021).]

|

|

|

|