|

| Modify upside-down Cadillac Seville rear calipers for easier bleeding (GA, LeBaron ) (Page 1/1) |

|

pmbrunelle

|

FEB 02, 11:56 PM

|

|

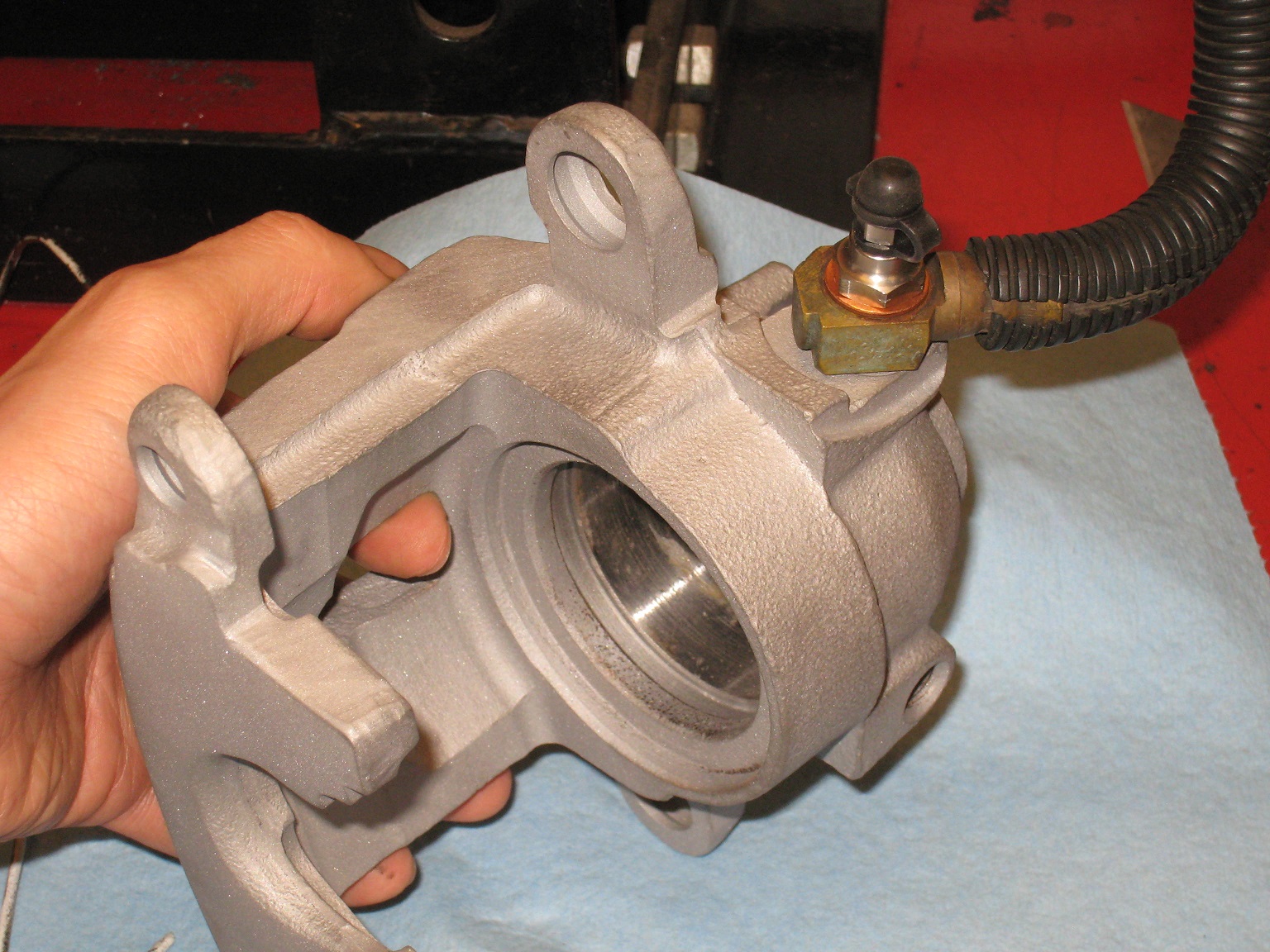

Perhaps you are using the Seville caliper with a Grand Am or LeBaron rotor in the rear...

GA:

http://www.fiero.nl/forum/A...14-2-083566.html#p28

LeBaron:

http://www.fiero.nl/forum/A...120111-2-109042.html

In many installs, the brake cable is routed below the CV joint, which results in the bleeder screw at the bottom of the caliper. As a result, air bubbles trapped inside the caliper cannot rise and exit through the bleeder. Typically, you have to unbolt the caliper and orient it right-side-up; it's a kludgy manoeuver.

With these brake setups, the banjo bolt is near the top... if only the air bubbles could escape via the banjo bolt, then the caliper could be bled in-situ.

For those that aren't aware, here is a banjo bolt bleeder :

In this writeup, I will explain how I modified my Cadillac Seville calipers to use banjo bolt bleeders.

So far, I have only performed this modification on the bench; road testing won't be for a while.

|

|

|

pmbrunelle

|

FEB 03, 08:58 AM

|

|

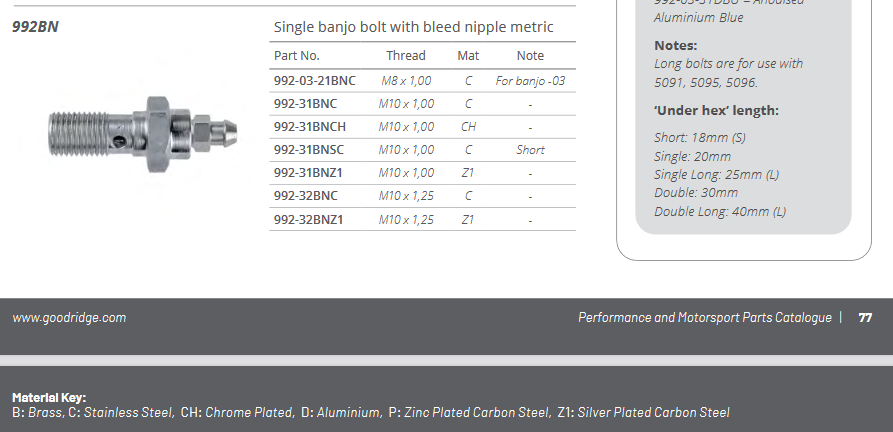

Here is an excerpt from the Goodridge catalog:

- M10 thread is required (to center the stock 10 mm banjo fitting and copper washers)

- 1.0 pitch is preferred, but maybe 1.25 could work (easier to cut threads for finer pitch)

- Stainless steel is nice, but zinc-plated steel should be OK.

- 20 mm length is pretty much required

I ordered the Goodridge 992-31BNC from the Internet.

- M10x1.0x20

- Stainless steel

|

|

|

jjd2296

|

FEB 03, 12:22 PM

|

|

|

so do these go in place of the banjo bolt? are you then mounting the brake line in the bleeder location? if so what are you using for that?

|

|

|

pmbrunelle

|

FEB 03, 01:02 PM

|

|

| quote | Originally posted by jjd2296:

so do these go in place of the banjo bolt? |

|

Yes, they replace the Cadillac banjo bolt.

| quote | Originally posted by jjd2296:

are you then mounting the brake line in the bleeder location? if so what are you using for that? |

|

The banjo bleeder bolt still functions in the usual manner to fix the brake line's banjo fitting to the caliper's fluid port. It's like a regular banjo bolt, just with a bleeder built in.

The bleeder location isn't touched... it's just a bleeder that can be used to drain fluid out the bottom, but it doesn't work to evacuate air bubbles.

|

|

|

pmbrunelle

|

FEB 03, 07:24 PM

|

|

The Seville caliper has an M10x1.5 banjo bolt thread.

The Goodridge banjo bleeder bolt (and others like it) has a thread size of M10x1.0.

Using a Heli-Coil, the original hole can be converted to work with the Goodridge banjo bleeder bolt. Alternatively, one could purchase custom-made banjo bleeder bolts that would be compatible with the Seville M10x1.5 thread.

To align the caliper with the drill press, I screwed an M10x1.5 bolt (head cut off) into the fluid port. Then, I tightened the drill chuck onto the bolt shank.

With the caliper hanging in the air, aligned with the drill press spindle, I adjusted the table to fix the caliper in position.

Once the caliper was fixed in place, I could drill and tap for the Heli-Coil.

I like to align the tap with a cone in the chuck. This keeps the tap straight, provided that you apply a slight downwards pressure on the quill.

I do not recommend installing the Heli-Coil wire just yet...

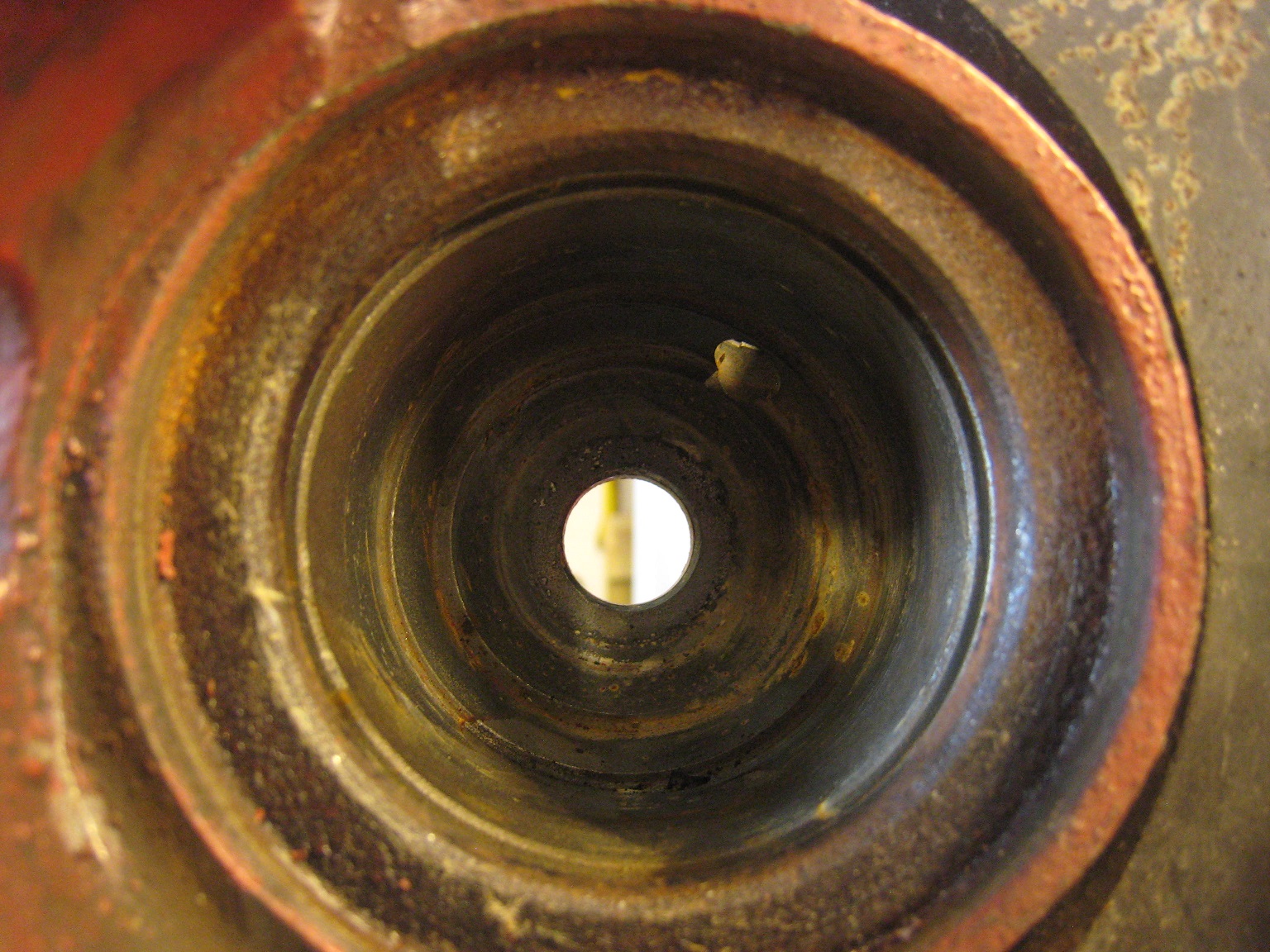

Looking into the caliper, we find that the banjo hole is not quite at the uppermost point of the caliper cavity. This could cause air to be trapped at the top of the bore.

To rectify this issue, a groove should be cut from the uppermost point of the bore, going towards the banjo bolt. There should be a slight constant upwards slope.

To cut this, I used a 1/4" spherical carbide burr on my Dremel. I also needed a 90° gearbox for the Dremel.

I bought this cheap Eyech gearbox from Amazon:

|

|

|

pmbrunelle

|

FEB 03, 08:13 PM

|

|

Once the groove is done, then the Heli-Coil wire can be installed.

There are two reasons to install the wire after cutting the groove:

1. Prevent damage to the wire while cutting the groove with the Dremel

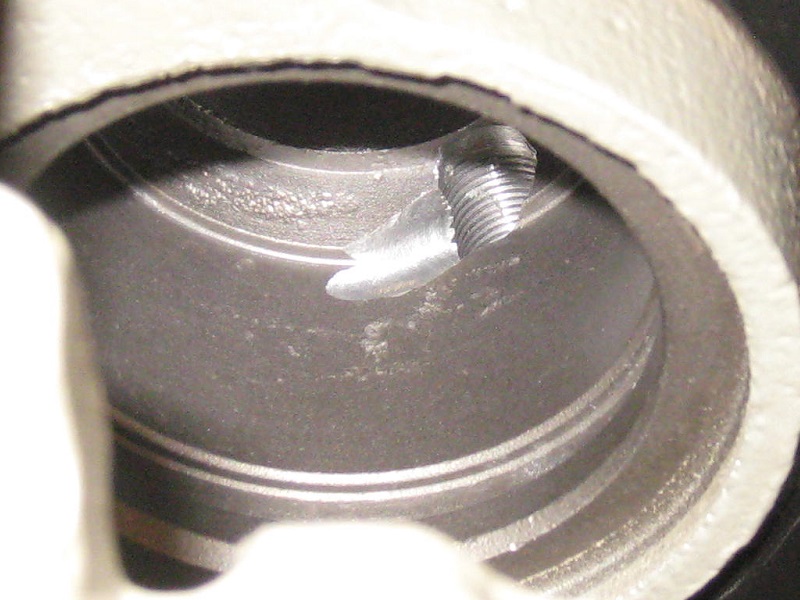

2. The wire must not penetrate down into the caliper deeper than the uppermost point of the groove. If the wire comes down too low, a high point will be created that could trap air. Until you cut the groove, it's hard to evaluate this.

Likewise, the banjo bolt face must terminate above the end of the Heli-Coil wire, to avoid creating an air trap.

Here is the final result viewed from the inside:

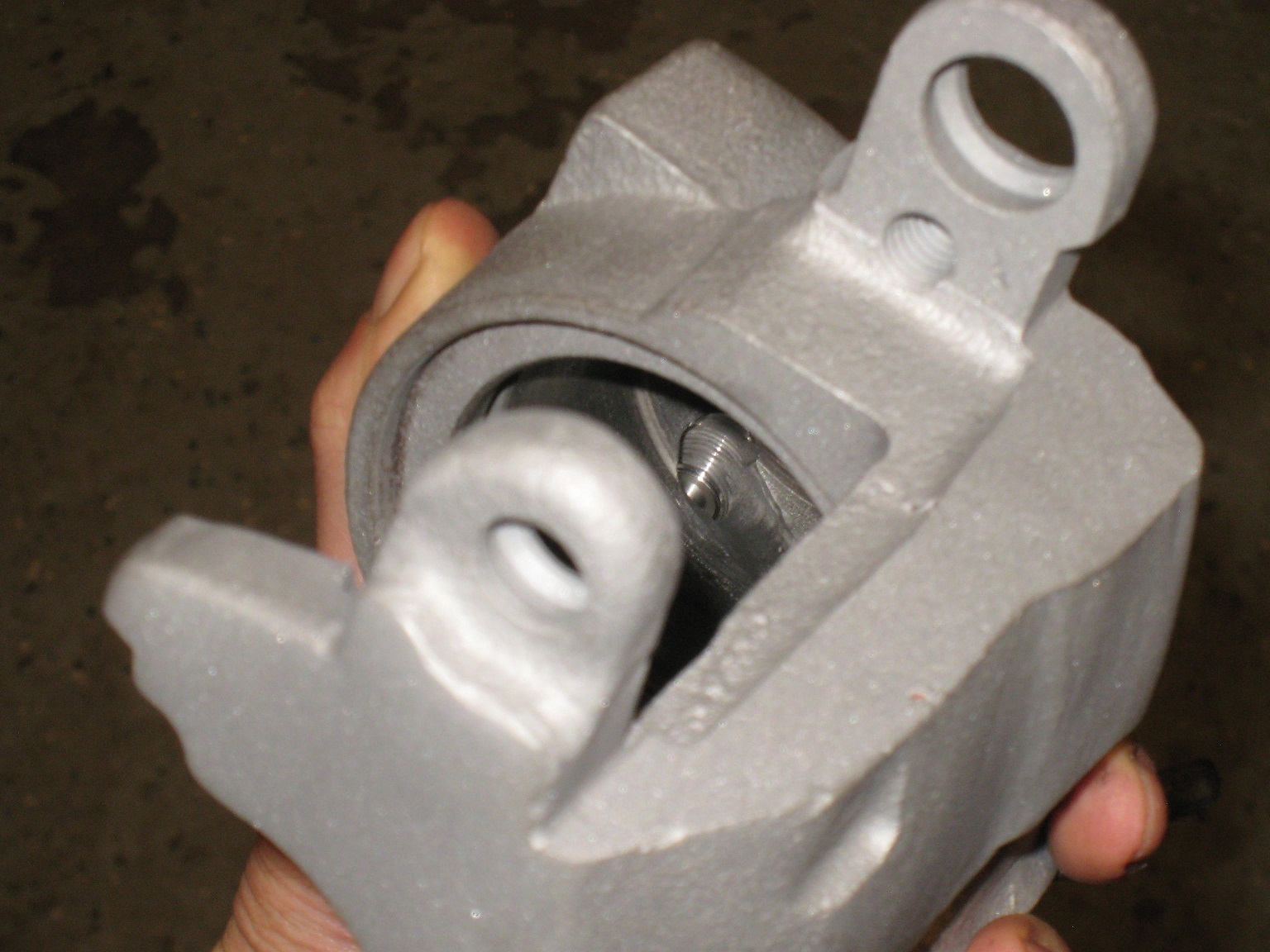

And the outside:

This test fit was performed with new copper washers and an old Fiero brake hose.

The original bleeder remains untouched at the bottom of the caliper.

|

|

|

Spoon

|

FEB 03, 11:06 PM

|

|

Very clever concept.

Spoon

------------------

"Kilgore Trout once wrote a short story which was a dialogue between two pieces of yeast. They were discussing the possible purposes of life as they ate sugar and suffocated in their own excrement. Because of their limited intelligence, they never came close to guessing that they were making champagne." - Kurt Vonnegut

|

|

|

pmbrunelle

|

FEB 04, 07:42 PM

|

|

| quote | Originally posted by Spoon:

Very clever concept.

Spoon

|

|

I just borrowed it from the motorcycle / powersports world!

|

|

|

Frenchrafe

|

FEB 05, 04:52 AM

|

|

Another "cheap" way to get the air out of these calipers is just to crack open the banjo bolt when bleeding the system.

A bit messy, but with some rags, an assistant in the car who holds down the pedal and just doing one caliper at a time, I've always had good rear brakes.

------------------

"Turbo Slug" - '87 Fiero GT. 3800 turbo. Sticky tyres. Driven hard!

https://www.youtube.com/cha...1wZvWQlkYxTjivW_0XNg[This message has been edited by Frenchrafe (edited 02-05-2021).]

|

|

|

|