|

| PRESSING THE OIL PUMP PICKUP INTO THE OIL PUMP (Page 1/2) |

|

eti engineer

|

MAR 07, 10:26 AM

|

|

|

Does anyone have a slick way of pressing the oil pump pickup into the port on the pump itself? The Melling pump comes this way, but the interference fit and tightness it creates makes it very difficult to press it in. I already have figured out where it needs to be and and marked it and plan on tack welding it once it is in place, but I haven't come up with a way to press it into place. Thanks in advance for any advice.

|

|

|

pmbrunelle

|

MAR 07, 05:57 PM

|

|

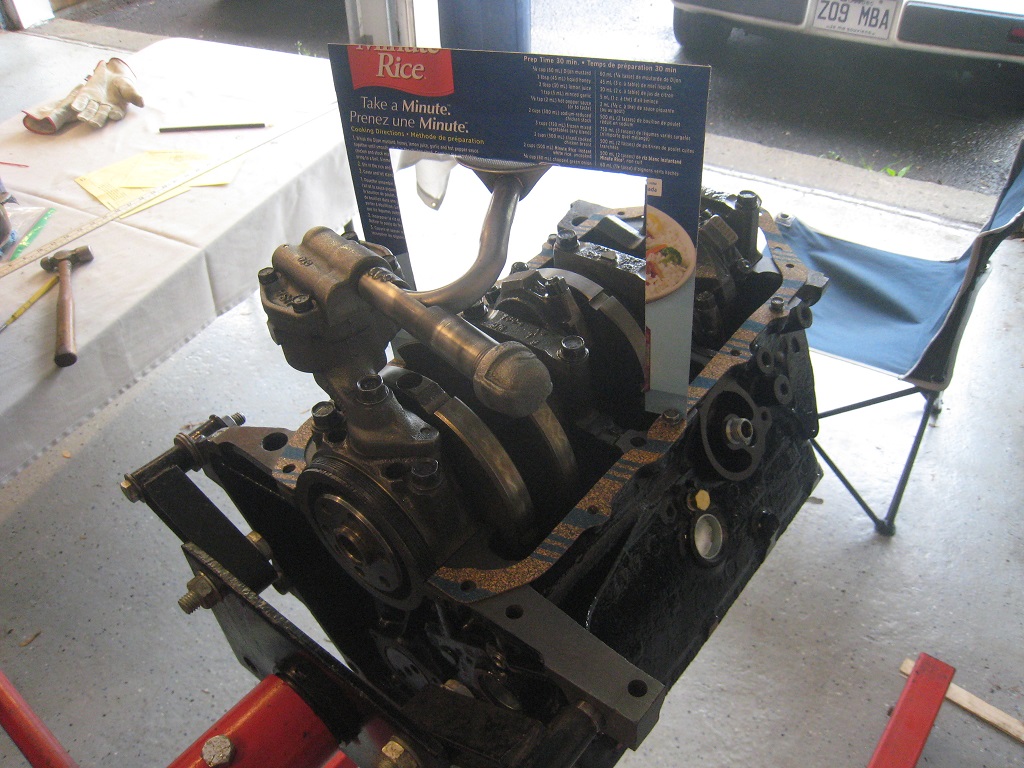

Pieces of pipe, with pipe cap, and cut as per photo.

Half-pipe sections tack-welded around the pickup tube.

Use hammer to hit the end of the pipe. Bolting the oil pump to the engine gives a steady base during this step. Also use a cardboard template to simulate the oil pan. The pickup must be at a certain distance from the bottom of the oil pan.

Once the pickup tube is pressed in place, take the assembly off the engine, and cut off the pressing tool.

Due to the questionable metallurgy of tack-welding steel to cast iron, I decided to silver-solder my pickup tube in place.

|

|

|

eti engineer

|

MAR 08, 04:51 PM

|

|

Thanks. I will use this method when I get my engine back from the build and start putting it back together. I like the idea of silver soldering. I have an oxy-acetylene setup from when I did air conditioning work and some sticks of silver solder. Sounds like a better idea.

One last thing, what diameter is the piping?[This message has been edited by eti engineer (edited 03-08-2021).]

|

|

|

fierosound

|

MAR 08, 05:10 PM

|

|

| quote | Originally posted by eti engineer:

One last thing, what diameter is the piping? |

|

Another DIY installation tool.

https://www.homemadetools.n...up-installation-tool

Use the open end of a wrench that fits snugly above the "bubble" to measure tube diameter.

I'm pretty sure that's all I used to tap the tube into the oil pump as well.

There's even a driver tool like that available for these things.

------------------

My World of Wheels Winners (Click on links below)

3.4L Supercharged 87 GT and Super Duty 4 Indy #163[This message has been edited by fierosound (edited 03-08-2021).]

|

|

|

pmbrunelle

|

MAR 08, 07:29 PM

|

|

I believe I used steel 1/2" NPS pipe, schedule 40.

Probably the best solution would be using a shaft collar:

This could be welded to a long rod which could be hit with a hammer.

I noticed that forum member fieroguru likes to use shaft collars welded in his projects, such as for securing shift cables.

|

|

|

La fiera

|

MAR 08, 09:19 PM

|

|

|

I used a chisel to put the pick up in place and then tack weld it or braze weld it.

|

|

|

eti engineer

|

MAR 09, 10:26 AM

|

|

| quote | Originally posted by fierosound:

Another DIY installation tool.

https://www.homemadetools.n...up-installation-tool

Use the open end of a wrench that fits snugly above the "bubble" to measure tube diameter.

I'm pretty sure that's all I used to tap the tube into the oil pump as well.

There's even a driver tool like that available for these things.

|

|

Thanks for your idea. I will be looking around, now that I have some ideas from those who have been here before...

|

|

|

eti engineer

|

MAR 09, 10:27 AM

|

|

| quote | Originally posted by pmbrunelle:

I believe I used steel 1/2" NPS pipe, schedule 40.

Probably the best solution would be using a shaft collar:

This could be welded to a long rod which could be hit with a hammer.

I noticed that forum member fieroguru likes to use shaft collars welded in his projects, such as for securing shift cables. |

|

All good ideas in here. Thanks for the post!!!

|

|

|

eti engineer

|

MAR 09, 10:28 AM

|

|

| quote | Originally posted by La fiera:

I used a chisel to put the pick up in place and then tack weld it or braze weld it. |

|

I plan on silver brazing once it is in place, as was pointed out in the first reply to this thread, there are dissimilar metals involved...

|

|

|

Tony Santucci

|

MAR 09, 04:31 PM

|

|

I've always used an open end wrench as well on all interference fit oil pick up tubes

|

|

|