|

| Wear causing slop in shift mechanism (Page 1/1) |

|

CSM842M4

|

AUG 31, 05:24 PM

|

|

|

While replacing cables on my '84 4-speed and '86 5-speed Isuzu's, I noticed that they use slightly different versions of the same mechanism to operate the shift shaft. I like the one on the 4-speed better, but only slightly. In both mechanisms, the pin/s that manipulate the shaft in and out of the transaxle case (the SELECT function) are worn to the point that it requires more travel from the shifter than it should. I can envision the wear getting so extreme that the shifter can no longer get the job done, if the situation is not addressed. Hence, this post. Has anybody come up with a working fix for this, other than finding a less-worn mechanism and swapping it in? Something that lasts? I know, there are enough other wear points in the whole shifting apparatus that this may be minimal, but a lot of those at least have the opportunity to come in contact with some lubricant inside the trans. And grease or lithium lube eventually wipe away... Any input is always appreciated. Thanks in advance - Chris

|

|

|

Rick Vanderpool

|

SEP 02, 02:12 PM

|

|

Check out Rodney Dickman's Fiero Transaxles page to see if he has what you are looking for.

Rick

|

|

|

CSM842M4

|

SEP 02, 05:18 PM

|

|

|

Thanks, Rick. I normally check all the "usual suspect" sources before posting here. Not this time. Regardless, Rodney shows to have cable brackets, slave cylinders, cables and such, but nothing for transaxle shift mechanisms. Same with TFS and West Coast. Perhaps I'm looking at some milling machine time...

|

|

|

Gall757

|

SEP 02, 05:32 PM

|

|

|

Usually the wear happens at the shifter end and not at the trans case end..... [This message has been edited by Gall757 (edited 09-02-2021).]

|

|

|

pmbrunelle

|

SEP 02, 11:56 PM

|

|

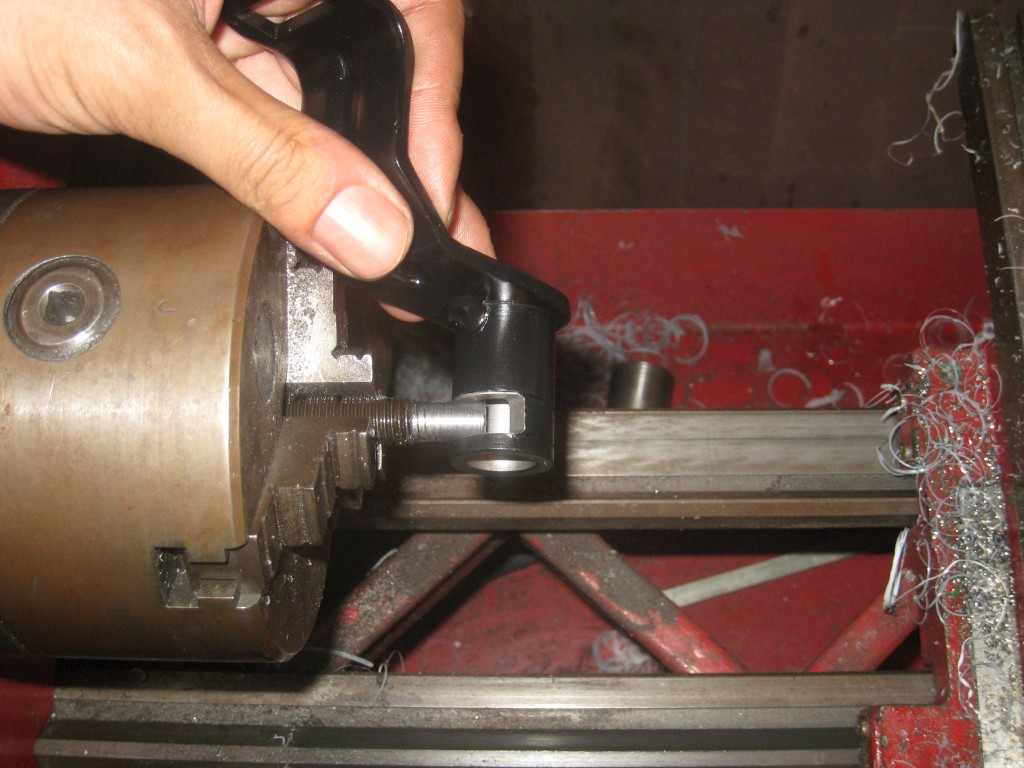

When I assembled my Frankenstein Muncie, I noticed wear on the pin you're talking about.

I made a replacement pin from a piece of scrap bolt (probably class 10.9), turned to just the right size to fit in the shift arm slot. The slot didn't appear worn out.

The pin can either be welded on (from the non-visible side in the photo), or brazed to facilitate replacement in the future.

The transmission has shifted nicely since the refresh. It's been about 12000 km since then. I actually have the transaxle out again for a clutch replacement job. I'll inspect the pin to see how it looks now.

|

|

|

CSM842M4

|

SEP 03, 11:32 AM

|

|

|

Thanks, Gall757 and pmbrunelle. Gall, when I first saw your reply, it looked lkke you had posted a couple of links to Rodney's website (I think). It's real possible that I overlooked some available parts in my haste to get to the milling machine. If it was you, could you post those links again?

|

|

|

CSM842M4

|

SEP 03, 11:56 AM

|

|

|

Hey, Gall757 - just visited Rodney.com and saw the select shaft rebuild kits for Isuzu's and Muncie's. That's real similar to what I did on the '84's 4-speed, but I think I used a shoulder bolt. Took care of the slop in the main pivot, but it remains in the pins and slots. I'm noodling with replaceable bushings throughout the pivot and replaceable pins and wear points in the slots. We'll see what happens. Thanks again - Chris

|

|

|

pmbrunelle

|

SEP 03, 12:00 PM

|

|

Back in 2016 when I did this repair, I thought that this part was a "Rodney Dickman style" product, so I did suggest to him that the pin(s) could be a useful product that he could sell. I offered him the dimensions of the pin I made, but back then it wasn't a project he wanted to take on. Low demand perhaps? He didn't share his reasons.

Since the wear occurs on the top and bottom of the pin, Rodney did suggest that the life could be doubled by rotating the pin 90°, so that it operates on the unworn areas.

|

|

|

|