|

| V8 exhaust (Page 1/1) |

|

batboy

|

OCT 22, 04:52 PM

|

|

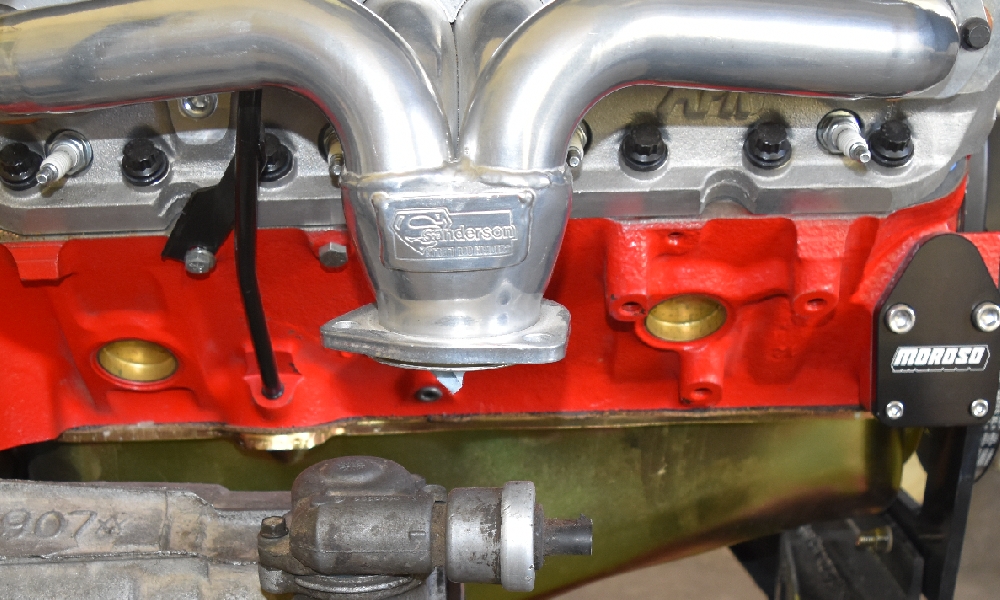

I have a rebuilt SBC engine and rebuilt TH125C auto trans mounted onto the cradle. I was looking it over and saw this (see photo 1). The governor and speed sending unit is smack dab in the way.

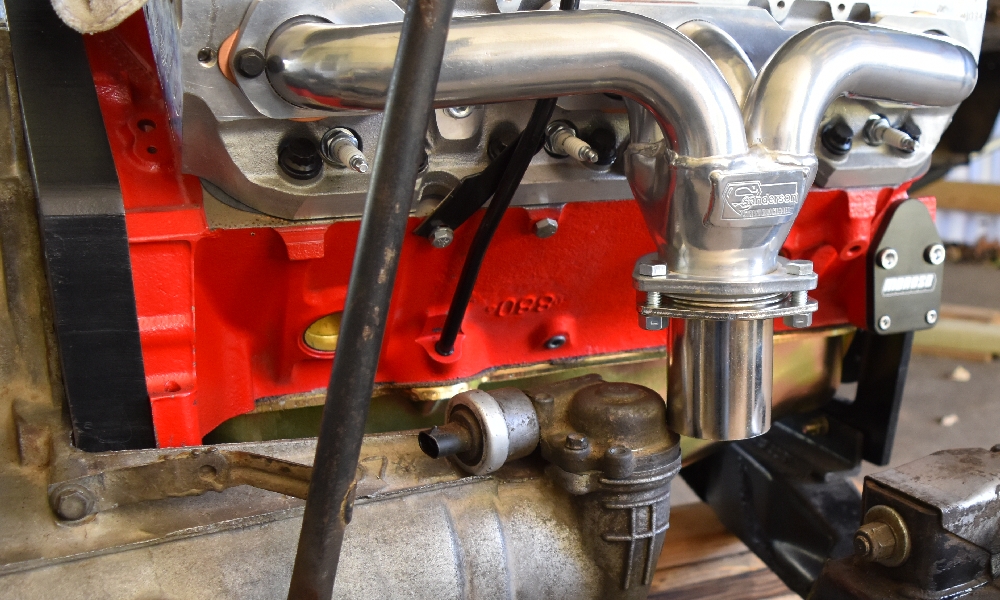

I did some searching and saw a thread where V8 Archie said this module be turned 180 degrees for more clearance. I tried that and it did help, but as you can see in the second photo, you still can't go straight down out of the flange. I assume that I'll need to do a 45 bend immediately out of the flange to the right and then another 45 bend to drop it down. From there a 90 degree bend, muffler, and another 90 before it goes out the tailpipe.

What has others done if the Sanderson C90 headers are used?[This message has been edited by batboy (edited 10-22-2021).]

|

|

|

IMSA GT

|

OCT 22, 08:36 PM

|

|

Sanderson makes angled header adapters. They say they're reducers but I'll let you see if these will work. That way you can have a gradual offset rather than a tight 90.

https://www.sandersonheader...educers-_angled.html

[This message has been edited by IMSA GT (edited 10-22-2021).]

|

|

|

pmbrunelle

|

OCT 22, 09:00 PM

|

|

You can buy some really tight pre-made mandrel bends from places like Summit Racing (or other vendor you prefer):

https://www.summitracing.com/parts/pte-h7059

You cut out a section of the U-bend, and then you weld it to your pipe. What exhaust pipe size do you have?

The straight section coming out of the flange could also be shortened by quite a lot. The weld with the bend could be like 1/2" away from the flange.

On my Fiero, I used a bend like that to keep the exhaust pipe from penetrating into the trunk:

For scale, that's a 2-1/2" exhaust pipe.

To cut exhaust pipes, I use a worm clamp + a Sharpie marker to trace the cut line. I then cut the pipe with an angle grinder + cutoff wheel.

|

|

|

batboy

|

OCT 22, 09:52 PM

|

|

Thanks for the responses. I never knew they had angled flanges. I'm going to try to use 2.5" pipes. I have three of the Speedway motors pre-bent pipes (each has a 180 and a 90 mandrel bends). I have the old exhaust to help figure out the new exhaust, but the manifold outlets on the old setup angled back (rather than straight down in the center) and it was 2" diameter with a few rust holes.

ADDED: I was about to order those Sanderson angled flange reducers. But, when I checked into it, they really are reducers. The 2.5" flange reduces down to 2.25". I don't want that constriction. I'm going to use the straight flanges I already have. On the close fitting side, I'll cut off all but 2 or 3 inches of the straight pipe and weld a 45 bend onto the pipe. Less chance of warping the flange, which I've done before.[This message has been edited by batboy (edited 10-23-2021).]

|

|

|

|