|

| The Resurrection of FieroJimmy's 1987 GT (Page 1/1) |

|

FieroJimmy

|

MAR 20, 08:39 PM

|

|

With the rising gas prices, I have decided it is time to get my GT back in shape and resume driving it. 13mpg in my truck is getting old fast.

I've had this car for about 20 years. I bought it from a family friend with what was described as an engine noise. I drove it home, and checked out the noise. It was failed water pump bearings. I replaced the water pump, and offered the car back to Sam. He declined, and thus, the car was now mine.

The vent window scoops and raised wing were on the car when I got it. Over the years I have done a multitude of things to it. Other than basic maintenance, I have lowered it 2" using Intrax springs up front and Ground Control coil-overs in the back. I did poly bushings in the front when I lowered it. I did not cut the bumpstops, so I have basically been riding on the bumpstops since then. I installed an Ocelot exhaust and ported stock manifolds. I added EL glow white face gauges. I installed a rebuilt engine when the engine actually did fail. It has a Crane PowerMax 2030 cam, Comp Magnum 1.52:1 roller tip rockers, and ported heads. It makes decent power, but like all stock intake Fieros, it is choked off on the top end due to the restrictions in the plenum.

I have neglected the car badly over the last several years, and have pretty much stopped driving it. A multitude of minor (and not so minor) issues have piled up and compounded to the point it isn't reliable enough to trust for any distance.

I installed Rodney's axle stabilizer bearing/seals years ago. They are (indirectly) the reason I have mostly stopped driving the car. I didn't get them properly sealed when I installed them, and they have been leaking since just after I put them in. I tried to RTV them from the outside. I even tried JB weld. Nothing I did could stop the leak. I would have to pull them and reseal them to the case, but I never got around to it. I got lax in maintaining the fluid level and driving home from Baltimore one day, the transmission began popping out of 5th. Further down the road it began popping out of 4th. I managed to hold it in 4th until I got home. Since then I have been (slowly, glacially slowly) working on rebuilding another Getrag to put in. I picked up a core to rebuild in Virginia, but it had a damaged case. Upon disassembly, I found the side gears had chewed into the diff case. I bought a replacement case half from Handymanpat. I also got a diff from him. It turned out that the trans he had was a newer FWD trans, so the case half I got was different. But the newer diff has the larger side gears. Rodney does sell an adapter to use the stock slave cylinder with the newer case, so I ordered one of those.

I am going to rebuild the steering/suspension, finish rebuilding and install my transmission, replace the rear calipers (one is leaking, and the parking brake is not adjusting properly). I have to repair some broken exhaust manifold bolts, and replace the exhaust as one of the muffler outlets has rusted off (to be fair, it was almost 15 years old). I have a weird slip in the steeering column under high steering torque situations (another reason I have not been driving it). One of the decklid springs has broken, so I have ordered one of Rodney's dual strut kits.

This thread is starting with some of the work in progress, so there won't be pictures of some of the early work.

|

|

|

FieroJimmy

|

MAR 20, 08:40 PM

|

|

|

<Saved for Table of Contents>

|

|

|

FieroJimmy

|

MAR 20, 08:45 PM

|

|

This weekend I have made some progress.

I have installed Rodney's decklid strut kit:

I have also pulled the steering column to address the slip while steering. I have narrowed it down to the column, since the intermediate shaft does not turn when the steering wheel does. I am suspecting that the problem is at the tilt pivot "ball." I think one of the yokes is slipping on/in the shaft.

Hopefully I have time to tear the column down tomorrow.

|

|

|

reinhart

|

MAR 21, 07:05 PM

|

|

|

Just curious why you chose not to just replace the decklid spring. The struts are good if you had to cut the hinges for an engine conversion, but I don't see any other reason for the struts. The springs aren't *that* difficult to swap out once you remove the decklid.

|

|

|

FieroJimmy

|

MAR 21, 07:19 PM

|

|

Mostly because I don't have a spare spoiler equipped spring laying around. Also, I do like the look of the struts. And, finally, because I just wanted to make the decklid stay up while I'm working on it NOW.

I miss driving it, and just haven't had the motivation to do ALL the little things that have piled up.

|

|

|

FieroJimmy

|

MAR 21, 07:42 PM

|

|

I took my column apart today, and I can't definitively point at a failure that would cause my "slip." Some background description of the "slip": I was turning the wheel left while stopped. (It was a cramped parking lot, and I barely had room to get out due to other's poor parking.) Suddenly the wheel jumped. I didn't think much of it, but when I got straightened out, the wheel was about 20 degrees off-center to the left. Later, I tried turning to the right while stopped, and the wheel jumped again. This time when I started driving the wheel was back to straight. It happens more often when it's cold out, near freezing.

I did grab the bottom of the column at the intermediate shaft coupler, and cranked the wheel. The wheel turned/slipped, but the coupler didn't. Whatever is wrong is certainly in the column.

I did find some wear on the inside of the lower column in a weird spot. It looks like the lower steering shaft has been contacting. There was a rub mark on the shaft, but because it is harder than the housing there is no damage to it.

The intermediate shaft coupler was very snug on the lower column shaft, as expected. Both pieces of the lower shaft are tight and fit properly. The injected plastic is intact. The plastic "ball" in the tilt joint needs regreased, but it has no play or damage. All the splines on the upper column shaft are in perfect-ish condition, nothing stripped or mangled beyond serviceability.

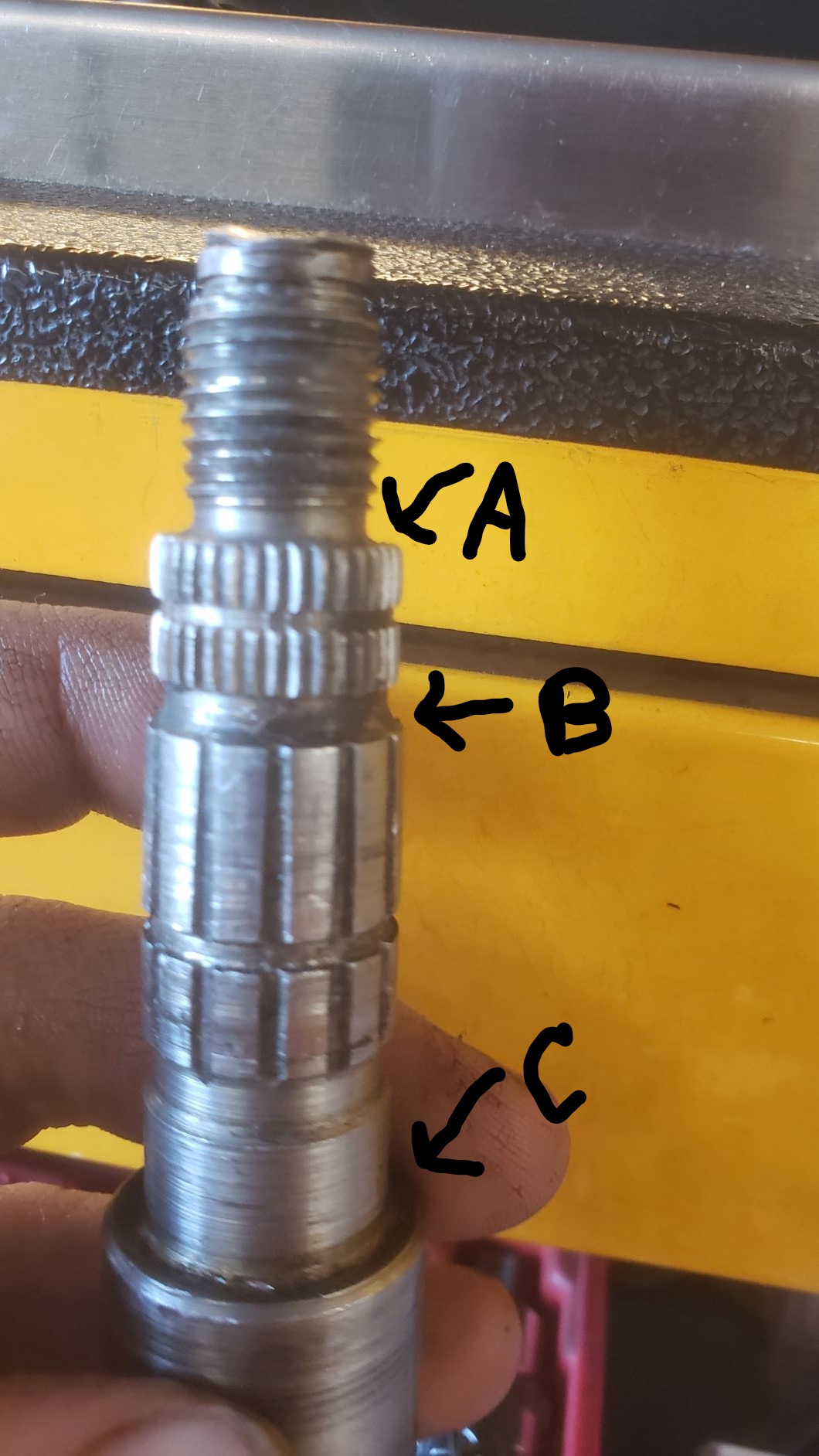

The one thing that I can see that might be a cause is if the upper shaft is actually manufactured in two pieces. I always assumed it was 1 piece, but now I'm not sure.

The three "upper" steps in diameter all have a radius or taper at the inner corner, as would be good design practice to prevent stress risers and the possibility of cracking that comes with them.

But, the first step, at the pivot ball, doesn't have one. There is typically a bearing race pressed on there, which may be why they didn't include one.

But, looking at the machine work for the actual pivot, it looks like there is a spot weld. There is a small circular spot with a heat affected zone around it.

I will take apart one of my spare columns and see what it looks like. I may just have to do some "destructive testing" on this one and see what it looks like when it's been cut in half...

|

|

|

reinhart

|

MAR 23, 09:21 AM

|

|

|

Wow that's a failure I've never seen/heard of before.

|

|

|

|