|

| Another engine miss issue (Page 1/4) |

|

Another One

|

APR 30, 06:18 PM

|

|

I have searched the forum as there are several threads related to engine miss but either they have no conclusion or they did not solve my issue. Here is what I have and what I have done.

Vehicle:1988 Fiero coup with the 2.8 V6 and 5 speed Getrag. Rebuilt stock engine with less than 2000 miles.

Symptoms: Idle fluctuates between 900 and 1150 RPM. Trying to hold any steady RPM causes the engine to miss, the higher the RPM the worse the miss. Hard acceleration while driving and it runs as expected but try to hold it steady at any RPM and it kicks and jerks severely.

Distributor has been replaced with a rebuilt distributor from The Fiero Store. Timing is set at 10 degrees BTDC and fires up instantly.

Disconnected tach filter, no change.

Cap, rotor, wires, plugs (NGK steel core properly gapped at .045”) have all been replaced with new. Plug wires have dielectric at both ends.

All ignition wires misted with salt water after dark and there are no visible sparks.

ICM swapped with another new ICM, no change.

ECM swapped, no change.

I have an old Snap On MT2500 scanner that feeds back info on the sensors. They read as follows:

MAP = .6 at idle, 4.9 at wide open throttle. Replaced with new and no change.

MAF I don’t remember the numbers but replacing it didn’t change anything.

IAC = 50 and fluctuates a little as the RPM changes at idle.

TPS = .5 and moves smoothly through the range. Replaced, no change.

O2 = 450 mv and never changes. This keeps the engine from going into closed loop so it will be replaced next but there is no O2 code.

I had 2 extra coils from the previous owner so I swapped those in. Problem got worse so I replaced the coil with a new coil. It performed the same as the coil that was installed when the problem started.

Fuel pressure does not build with key on but does when cranking, 38 psi. I know it should turn the fuel pump on for 2 seconds at key on so that’s an issue but I don’t believe it’s my idle issue. Depending on demand, fuel pressure is between 38 and 50 psi.

Checked for vacuum leaks by using carb cleaner over entire vacuum circuit with no change to performance.

EGR has been replaced. No vacuum at EGR because engine is staying in open loop mode. No apparent leaks in the EGR tube.

Cleaned all ground wire connections including at the ECM. Added an additional ground from engine to frame.

If I hook the timing light to each individual plug wire, hold RPM around 1500 and watch the flash pattern, there is a very noticeable miss on cylinders 1, 3, and 5 and an occasional miss on 2, 4, and 6.

I have a new EGR tube and stainless-steel vacuum lines ordered from Rodney just to make sure those aren’t the issue.

So many times I was sure I was headed in the right direction to find out I wasn’t. I’m down to just throwing money at it and I’m not really in a position to do that so any input or thoughts would be greatly appreciated.

|

|

|

Patrick

|

APR 30, 07:13 PM

|

|

| quote | Originally posted by Another One:

Depending on demand, fuel pressure is between 38 and 50 psi.

|

|

Proper fuel pressure: 40.5 - 47 psi Engine (fuel pump) on, 30.5-44 Psi Engine Idle.

How quickly does the fuel pressure drop when the engine is turned off.

| quote | Originally posted by Another One:

Timing is set at 10 degrees BTDC...

|

|

With ALDL jumper installed? And have you verified that the outer ring of your harmonic balancer has not slipped? If it has (and this isn't uncommon), your ignition timing will be all off.

| quote | Originally posted by Another One:

O2 = 450 mv and never changes. This keeps the engine from going into closed loop so it will be replaced next but there is no O2 code.

|

|

That would've been the first thing I'd rectified.

|

|

|

olejoedad

|

APR 30, 07:28 PM

|

|

There is no MAF on a 2.8.

Use copper core plugs with GM distributor/HEI ignition.

|

|

|

Another One

|

APR 30, 07:33 PM

|

|

Fuel pressure is 50 psi when the engine is shut off and holds for at least 30 seconds. I didn't time it because I figured 30 seconds of the pump not running meant any leak was minimal. If that's wrong please let me know. According to your numbers, it is a little low at idle. Any increase in RPM causes the pressure to increase over 40 psi.

I forgot to mention that the fuel injectors were cleaned and spray pattern looks great. I have a buddy that has a contraption that hooks up to the injectors (1 at a time out of the engine), applies about 60 psi of cleaner and turns them on/off till all the cleaner has run through them.

Ignition timing was set with the ALDL jumper installed. How can I check the harmonic balancer to see if it's slipped as I have not checked that?

I agree on the O2 sensor but I only found about it last night as it is not setting a code. Headed to parts store shortly.

Thanks for the info.

|

|

|

Patrick

|

APR 30, 07:52 PM

|

|

| quote | Originally posted by Another One:

Fuel pressure is 50 psi when the engine is shut off and holds for at least 30 seconds. I didn't time it because I figured 30 seconds of the pump not running meant any leak was minimal. If that's wrong please let me know. According to your numbers, it is a little low at idle. Any increase in RPM causes the pressure to increase over 40 psi.

|

|

Fuel pressure should slowly dissipate over several minutes. 30 seconds is nothing. You're losing pressure somewhere.

And you're saying that your fuel pressure goes up to 50 PSI, yet is below the minimum reading of 30.5 PSI with the engine idling? Something isn't right.

| quote | Originally posted by Another One:

How can I check the harmonic balancer to see if it's slipped as I have not checked that?

|

|

With the spark plug removed from cylinder #1, use something like a plastic straw inserted into the hole to find TDC while moving the crank by hand. When this has occurred, the wide timing mark should be lined up with 0° on the timing scale.

|

|

|

Gall757

|

APR 30, 08:39 PM

|

|

| quote | Originally posted by olejoedad:

Use copper core plugs with GM distributor/HEI ignition. |

|

Repeat for emphasis....I don't know why, but it really makes a difference!

|

|

|

Another One

|

MAY 01, 12:28 AM

|

|

Patrick,

I apologize, I misunderstood the fuel pressure numbers you posted. Attention to detail is everything and I failed today.

There is no fuel pressure at key on so that is the next problem to solve. If you have any input, I will gladly listen. Bump the ignition with out starting the engine and fuel pressure is between 38 and 42 psi. At idle the fuel pressure is between 40 and 42 psi.

Key off and the fuel pressure was 48 psi. Two minutes later it was 47 psi. 5 minutes later it was 44 psi. My fuel pressure gauge is in 2 psi increments so these numbers are a close approximation. Basically about 1/2 psi per minute. If you believe this could still be a problem then I can and will test it longer.

O2 sensor has been replaced and there is no change in condition. The Snap On MT2500 scanner shows the O2 sensor reading between 423 mv and 458 mv depending on throttle position. I'm not sure what numbers should be seen on the O2 sensor but it is changing now as the old one was not. Still not making it to closed loop mode. I'm not sure what it takes to go to closed loop mode.

I did not check the harmonic balancer but it fires up real quick so if it is off, it's not by much. I will check it tomorrow to confirm. I have a long reach micrometer (.001 mm or .00024 inch) that will hopefully reach the piston. If not I will use the stick by eye method.

OleJoedad,

The rebuilt distributor, ICM, rotor, and cap were bought from the Fiero store so I presume they are correct although I have swapped the ICM (voiding the TFS warranty) to eliminate that as a possible cause. Car was running good for awhile as another Fiero fan saw it in town and posted a picture of it a few years ago. I read somewhere on the internet (possibly here?) that copper core vs steel core plugs increased resistance and stressed the already weak GM ignition system. I understand that it may be inaccurate so I will get copper core tomorrow and try that as well.

I'll swap to the original distributor tomorrow and see what happens although it has run good on this distributor. It was swapped because I believed the pick up coil was going bad. I know the logic doesn't make sense but I ran out of logic just before I ran out of money. I've given up on being able to explain why, just want it running good again.

|

|

|

Patrick

|

MAY 01, 02:01 AM

|

|

| quote | Originally posted by Another One:

Key off and the fuel pressure was 48 psi. Two minutes later it was 47 psi. 5 minutes later it was 44 psi. My fuel pressure gauge is in 2 psi increments so these numbers are a close approximation. Basically about 1/2 psi per minute. If you believe this could still be a problem then I can and will test it longer.

|

|

The fuel pressure drop sounds fine.

| quote | Originally posted by Another One:

There is no fuel pressure at key on so that is the next problem to solve. If you have any input, I will gladly listen.

|

|

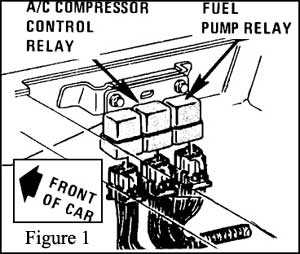

Electronics aren't my strong suit, but have you checked the fuel pump relay mounted on the firewall? If you have A/C, you can swap the relays for testing purposes

| quote | Originally posted by Another One:

Still not making it to closed loop mode. I'm not sure what it takes to go to closed loop mode.

|

|

Coolant temperature for one. What temperature thermostat do you have installed? What temperature does your scanner tell you that the engine is reaching?

| quote | Originally posted by Patrick Here:

The A/F mixture will be influenced by both the MAT and coolant temperatures (a colder engine requires a richer mixture), so it's important to know what readings are being sent to the ECU when the engine is fully warmed up.

I also like to occasionally check the MAT and coolant temperatures first thing in the morning after the engine has sat all night, to make sure these two readings are very similar. The engine isn't running for this test. If the readings of the cold engine aren't close, at least one of the temperature sensors is probably faulty.

|

|

[This message has been edited by Patrick (edited 05-01-2022).]

|

|

|

olejoedad

|

MAY 01, 07:48 AM

|

|

Just for grins and giggles, put a plug in the vacuum line to the EGR valve an see if the problem goes away.

A slight leak in the EGR tube could also cause the problem, maybe a tiny crack or a gasket problem at either end.

Have you verified that the air tube below the throttle body into the upper intake is in good shape and properly seated?

|

|

|

theogre

|

MAY 01, 08:39 AM

|

|

"One Wire" O2 sensor is a Myth...

Is a Tan "Ground" bolted to block that is the Return Line for this. Sim problem w/ "ground" between ECM and ICM, See my Cave, Ground "Myth" notes

Clean/Fix All "Grounds" bolted/screwed to engine and frame. Coat ends w/ brake or dielectric grease.

Do that before replacing more parts.

Because New O2 will have problems w/ iffy Tan "Ground."

Note: O2 sensor will not switch when < ~ 600°F. Depending on location, can take a while to reach that starting when cold or even engine hot but off so exhaust cools. In some setups, can drop back to open loop even while running at idle for too long.

Is why some state inspection have a "Warning" to bump the gas for ~ 1 minute before E-test to keep O2 and Cat Hot.

get another ECM scanner or make sure you use right program for this...

Fiero Engines does Not have a MAF and Other Field(s) can be wrong having no data or wrong data.

Test MAP needs hand vac pump w/ gauge. See my Cave, Sensors Quick Ref

------------------

Dr. Ian Malcolm: Yeah, but your scientists were so preoccupied with whether or not they could, they didn't stop to think if they should.

(Jurassic Park)

The Ogre's Fiero Cave[This message has been edited by theogre (edited 05-01-2022).]

|

|

|

|