|

| TBI Test Adaptor for Duke etc. (Page 1/2) |

|

theogre

|

MAY 22, 10:00 PM

|

|

In my Cave, TBI Test Adaptor shows two type of units.

Today had to use one and camera handy to how to install.

Is for under car filter location but other have similar "rules."

1. Undo 1 line at the filter. I use outlet side because inlet nut is "welded" w/ rust to the line. (Is not fun replacing the filter either to avoid cross threading.)

2. Undo filter holder bolt.

Optional. Undo bolt and plastic hanger for heater pipes. Take bolt out, open the clamp, slide sideways to remove. This gets more room for outlet side of filter.

3. Undo 2 (or more) line hanger clamp. One hanger has 2 lines and must be careful to pry bolt end open.

4. If done right, metal lines to into "rubber" section you can't see easy. Install filter then line.

Test fitting rotate around the core.

Do Not leave the adapter long term. A day or three max. Because 3 Unknown O-rings in/on it may not last long.

Adapter Do Not come w/ a cap. I added an old R12 AC cap w/ seal to get second seal.

If you had V6 etc w/ builtin schrader but body is damage... might a workaround but even less to trust for high pressure systems.------------------

Dr. Ian Malcolm: Yeah, but your scientists were so preoccupied with whether or not they could, they didn't stop to think if they should.

(Jurassic Park)

The Ogre's Fiero Cave

|

|

|

Dennis LaGrua

|

MAY 26, 10:43 AM

|

|

|

I always wondered why GM never installed a Schrader valve fitting on the Duke fuel line. The only way to check fuel pressure is with the adapter or by installing a fuel pressure gauge that uses an electrical sensor. ------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

theogre

|

MAY 26, 02:37 PM

|

|

Because 300 220 and 700 TBI's have no way for them. (V6/V8 uses 220 TBI w/ 2 injectors same type as 300 TBI for 4 cyl.)

Schrader valves need enough extra metal on the "rail" to press, thread or crimp the valve case/body and none of those have a spot to mount them even w/ redesign air cleaner.

Get an old V6/V8 rail and pull/cut the Schrader valve out then look at the TBI to find anywhere to add metal to mount the body. That valve body is "huge" next to 700 and other TBI "rails." Then likely have to completely redesign the air cleaner etc just to allow it.

700 left has Throttle arm, Front PCV port and EGR, right TPS and Fuel ports, rear Vac ports. And Fuel doesn't flow in the lower section too. Air cleaner mounts below Injector, regulator and most of the "rail." 300 and 220 often have same problem.

Maybe other spots where above will fit but not writing a book how to use on every engine w/ those TBI's.

Example: for 87-88 4cyl... Looks like above might fit feed line near battery w/ rubber section but is big pain to pull the battery to access the joint and may not be ably to tighten the adapter anyway there.

Is likely why early dukes had Filter near the 300 TBI. While easy to change filters, also easy to use the "Bypass" adapter that just replace the filter. This "Bypass" adapter was easy to get 20+ years ago too.

T'ing of a Line have issues too. 1 issue can put load when use or just hit by anything and break. Same problem as many AC test ports even when "hidden" to prevent that. Many Fiero AC have damage or broken High AC port because can get hit by spare tire etc. Worse target if have R134 adapter on them.

Many other engine don't have Schrader valve and why many "pro kits" have so many ways to install fuel test gauges including other "shims" sim to above to insert fittings so you don't cut lines.[This message has been edited by theogre (edited 05-26-2022).]

|

|

|

Dennis LaGrua

|

MAY 26, 09:55 PM

|

|

|

I believe that a T fitting on the fuel line will work quite nicely. We are dealing with a relatively low fuel pressure. You alluded to this being done on A/C lines so it should work on the Duke. I like reading the fuel pressure with the engine running. Some guys say just break the fuel line at the filter and measure it with a gauge but this is static pressure not pressure under load. That adapter that you show that screws into the throttle body seems ideal. ------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

Patrick

|

MAY 26, 10:08 PM

|

|

| quote | Originally posted by Dennis LaGrua:

Some guys say just break the fuel line at the filter and measure it with a gauge...

|

|

I'm one of those guys.  I agree that it would be ideal to be able to measure the fuel pressure while the engine is running... but sometimes all you really need to know is if there's enough fuel pressure for the engine start/run. Putting a gauge on the disconnected fuel line and energizing the fuel pump works just fine for that. I agree that it would be ideal to be able to measure the fuel pressure while the engine is running... but sometimes all you really need to know is if there's enough fuel pressure for the engine start/run. Putting a gauge on the disconnected fuel line and energizing the fuel pump works just fine for that.

|

|

|

theogre

|

MAY 26, 11:55 PM

|

|

open a line and read pressure may tell pump is working but not system pressure even w/o engine running.

Worse... That's "stall load/pressure" on the pump and can burn it out very fast.

Is similar stall loads for HL and other motors that can fry them too when control relays etc don't work.

Even ignoring constant Fuel Flow is Coolant and Lube for the pump.

Either adapter reads system pressure whether or not engine runs. Not just mean you need "12v" into ALDL G.

This is important when have problems w/ regulator or return line that can cause low or high system pressure.

I have a fuel gauge set but can't find it right now. Even have 0-15 0-30 gauges to put on to read low pressure Duke uses better.

While fix the problem that pointing to iffy fuel parts, still want system pressure to see if GM screwed the reg too tight causing BLM to peg a lot in ECM data stream.

|

|

|

Patrick

|

MAY 27, 12:20 AM

|

|

| quote | Originally posted by theogre:

Worse... That's "stall load/pressure" on the pump and can burn it out very fast.

|

|

I get it, I get it... but it takes about one second to get a reading.

|

|

|

theogre

|

JUN 16, 12:53 AM

|

|

⚠️ Warning: Don't use above for days or longer.

Has 3 O-rings, 1 you see and 2 hidden, and any can "melt" because many use standard black rings dissolve shrinks or otherwise leak.

I left in inline for last few days again while car is down and today was leaking.

Before next use will need to find gas happy O-rings like ones use by filter and other joints.[This message has been edited by theogre (edited 12-28-2022).]

|

|

|

theogre

|

NOV 06, 11:35 AM

|

|

Update:

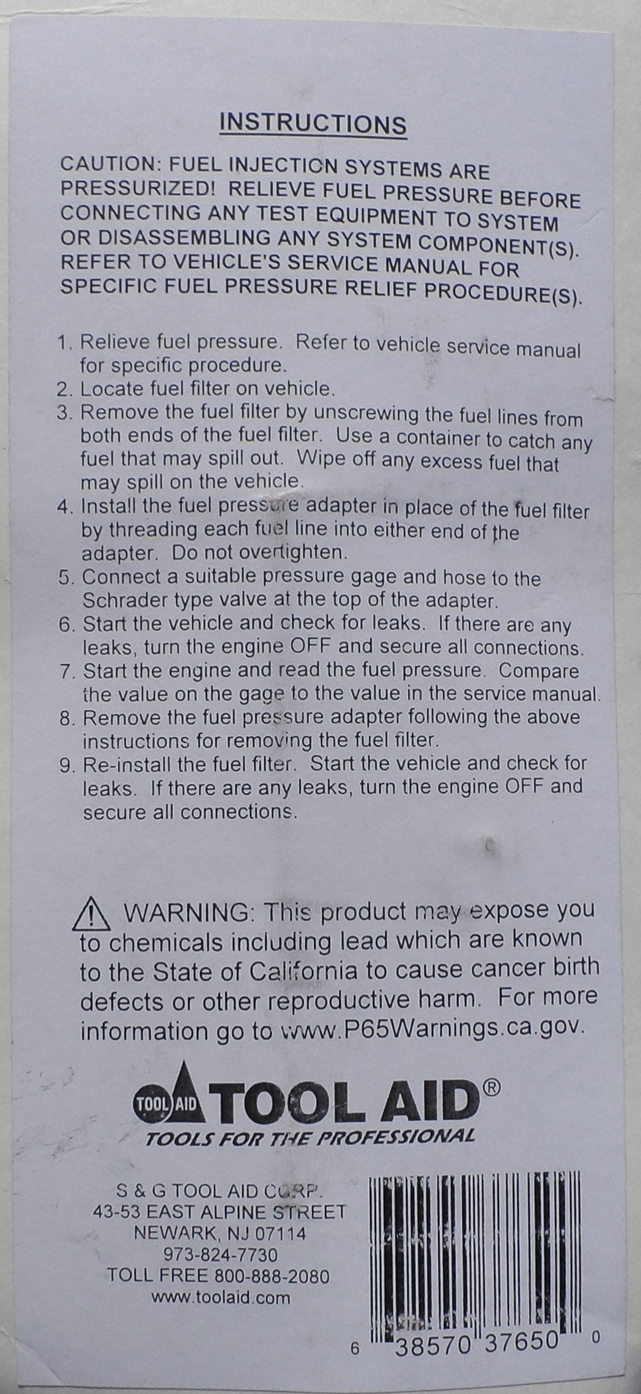

you can get 2 types of them @ amazon using search for "tbi fuel pressure tester adapter"

Above Adapter is sold under "OEMTOOLS GM RBI Adapter" and isn't a Ogre Typo but how it is listed and labeled.

https://www.amazon.com/OEMT...dapter/dp/B07CWW4ZQT

And Does Not have an external retainer ring that needs "pin pliers" to remove them as shown. Just a cheap simple snap ring.

New they are tight but if they have wrong seal type the valve body will leak soon as gas shrinks the o-rings.

Is cheaper but expect to use 1 time...

Other type replaces the filter same as shown in cave was sold under OTC & Equus...

This one under Tool Aid in NJ... Note: Label doesn't say where made. Listing said China.

https://www.amazon.com/Tool...dapter/dp/B0002SR544

silver part is made of steel.

|

|

|

theogre

|

JUL 11, 08:34 AM

|

|

⚠️ Warning: F-pressure gauges set sold everywhere don't work @ low pressure like 9-13psi.

"Bourdon" mech Gauges often made very actuate around middle 1/3 of range, not very or worse @ top or bottom. Many fuel sets are setup for 0 -100PSI or more gauge because most Port FI systems running @ 40 - 60 PSI. (Ignoring GDI engines that can go way higher then 100PSI.)

So this type gauge set may say 12 can be < 9 or > 13.

Buy or loaner tool the set & buy 20 - 30 PSI gauge & switch the gauge then back if you have to return under loaner program @ AZ etc.

Note: You have same problem w/ carb engines because often runs @ ~ 3 - 7 PSI.[This message has been edited by theogre (edited 07-11-2024).]

|

|

|

|