|

| J30R10 intank fuel hose. (Page 1/1) |

|

theogre

|

JUL 06, 11:55 AM

|

|

Many know to get J30R10 immersible fuel hose for pump replacements. This has been important even before gas has Ethanol now...

Most or all that posted here use 5/16" (~ 8mm) and works for most people....

⚠️ Warning: But steel fuel line to the pump for 87 Duke likely 88 Dukes are Not 5/16" line but 3/8" Line.

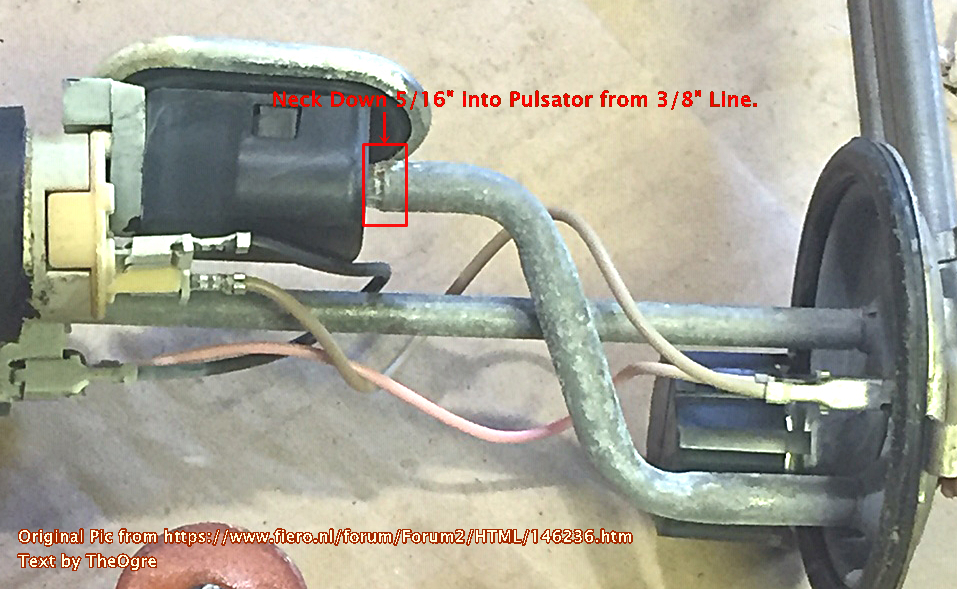

GM to save pennies stop "Necking Down" the Steel Feed Line from the pump.

87-88 V6 likely still requires the steel line at the joint to be 5/16" because of the pulsator only fit that size. But Dukes only use thick rubber and doesn't care about the pump output and line are different sizes.

If you think cost for 5/16" J30R10 is high... 3/8" is often higher cost for 1 foot and often very hard to get.

You may "get away" and force some 5/16" hose on 3/8" line but likely will fail soon down the road. Most hose won't fit bigger line at all. So get 3/8" "rubber" and clamp down to 5/16" on pump output is better.

You can see a V6 shown part of the "neck" section of line in https://www.fiero.nl/forum/Forum2/HTML/146236.html ... (Edit to highlight that section...)

Was very pissed because of this issue and didn't take pictures of 87 Duke fuel setup at the time.------------------

Dr. Ian Malcolm: Yeah, but your scientists were so preoccupied with whether or not they could, they didn't stop to think if they should.

(Jurassic Park)

The Ogre's Fiero Cave

|

|

|

sanderson231

|

JUL 08, 04:28 PM

|

|

It might be possible to slip 5/16" tubing inside the 3/8" tubing (if 0.035" wall) and sil-braze. Grainger has 5/16" automotive tubing for $6.43 a foot.

If you have access to a lathe, it would be a simple matter to machine an adapter and sil-braze it to the 3/8" tubing.

|

|

|

theogre

|

JUL 08, 07:36 PM

|

|

Do Not silver-solder or braising for the tube. Often that needed way to much heat and cause cracking in other spots or other problems.

Can use Lead Solder for normal Plumbing work. Just make sure tubes overlap ~ 3/8 to 1/2"

Can also use Self Tinning Flux even if many are lead free products.

But inside of small tubing can hard to clean.

Not Sure if the tubes and/or tank have Galvanize and other coatings that are dangerous to breath... When sanding or heating do it Outside for this reason.

|

|

|

sanderson231

|

JUL 08, 11:50 PM

|

|

|

Theogre, I respect your willingness to post helpful information. However, I draw the line when opinions are presented as authoritative fact. There is absolutely no risk in sil-brazing carbon steel to carbon steel. In the 1980's I raced bicycles. In that era steel was the common material for bicycle frame construction. High end bicycle frames with high tensile strength tubing like Reynolds 753 using lugged joints and were sweated together with high silver content brazing rod. Overheating of the tubing was a concern as it could anneal the tubing causing loss of tensile strength. Another method of construction is fillet brazing with brass rod. This requires the steel to be heated to a mild red. I know a professional frame builder who built over 100 tandem bicycle frames using the fillet brazing technique. I personally built three frames with this technique. There are many other frame builders using this same technique. Another method that came around in the 1980's was to TIG weld the steel tubing (even higher temperature - base metal melts). We are talking 0.035" wall tubing. I have a bicycle of this construction that has many miles on it. Sil-brazing is fine. It doesn't even require the steel to be red hot. In fact if you get it too hot the flux fries and you have to start over.

|

|

|

theogre

|

JUL 09, 02:43 PM

|

|

And You Ignore Many Will read above that as "old school" Bazing etc that need the Very Hot Metal that can wreck the tube. Because many have No Clue WTF sil-brazing is and Won't bother to look it up or get materials for a one use repair. Those are the targets of that warning.

Anything that doesn't need high high is good.

But Now likely some will think can "glue" w/ epoxy or whatever and that will likely fail even if the glue is "rated" to fix gas tanks and non-pressurize parts.

Self Tinning Flux helps prevent over heating flux making a huge mess. You can get it in minutes going to HD Lowes etc Today.

You put heat on and just watch the surface color change then remove the heat. A bit harder to see on steel but color change still happens. If you still burn some flux is easy to remove the trash and tinning is still there unless you burn the that too w/ a lot of heat.

|

|

|

sanderson231

|

JUL 09, 11:49 PM

|

|

I'm not against using plumbing solder for this application if all you have is propane or MAPP gas.

I sil-braze because 56% silver rod flows really well even better than lead-tin.

I already told you that steel bicycles frames with 0.035 wall can be fillet brazed with "old school" brass rod. What is your technical basis for saying that "old school" brazing will cause failure of the base metal. With either of the repair options I cited earlier, I could easily do it with brass rod.

I have been sil-brazing, brazing and gas welding for 45 years. I have never seen anything crack including butt-welded 0.040" wall exhaust tubing.

|

|

|