|

| TH125C low line pressure after installing shift kit (Page 1/2) |

|

James_GT

|

AUG 05, 10:39 PM

|

|

Last year I attempted a TransGo shift kit install on my '87 GT, but may have overestimated my ability to do it right. I took my time and was very careful throughout the entire process, since this was my first experience of disassembling the valve body. Unfortunately, the end result has been a slight 2-3 shift flare at medium throttle, delayed kickdown into passing gear, and soft and early gear changes.

I confirmed there is a low line pressure problem with a gauge. When the trans. is cold, all pressures are within spec except reverse (~40 PSI below spec) @ Max T.V. Reverse drops to around 115 PSI @ Max T.V when trans. is warmed up, when it's expected to be 230+ PSI. Drive, 2nd & 1st are all 20-40 PSI below spec, except Drive @ Min T.V.

Factory Pressure Specs - 7CPC - @ 1000 RPM

-------- Min T.V -------- Max T.V

P ------- 66-74 ----------- 66-74

R ------ 117-129 -------- 232-258

N/D ---- 67-74 --------- 133-147

I/L ---- 114-126 ------- 114-126

Line Pressure Test #1 - Trans. Cold @ ~850 RPM

-------- Min T.V -------- Max T.V

P --------- 78 --------------- 78

R -------- 115 -------------- 190

N/D ----- 70 --------------- 138

I/L ------ 120 -------------- 118

Line Pressure Test #2 - Trans. Hot @ ~850 RPM

-------- Min T.V -------- Max T.V

P --------- 70 --------------- 70

R -------- 113 -------------- 115

N/D ------ 68 ------------ ~100

I -------- ~95 ------------- ~95

L -------- ~75 ------------- ~75

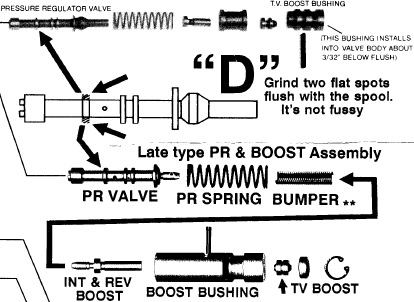

I'm unsure where I've gone wrong. The trans. has never had an issue prior to the shift kit install at 120k miles. Fluid level is normal. T.V cable set correctly. No problems selecting gears. My main concern is whether I've taken too much material off the pressure regulator valve. TransGo instructions suggest grinding two flat spots flush with the spool, allowing fluid to continuously flow to the converter.

As a temporary fix, I increased the line pressure manually with the T.V cable which resulted in a harsh 1-2 shift, soft 2-3 (no flare), and higher shift points. I'm confident the T.V valve is working normally, but I still seem to be losing pressure somewhere. Any advice on this would be greatly appreciated, thank you.

------------------

James

RHD '87 GT 3.4L V6[This message has been edited by James_GT (edited 01-18-2023).]

|

|

|

James_GT

|

AUG 07, 05:39 AM

|

|

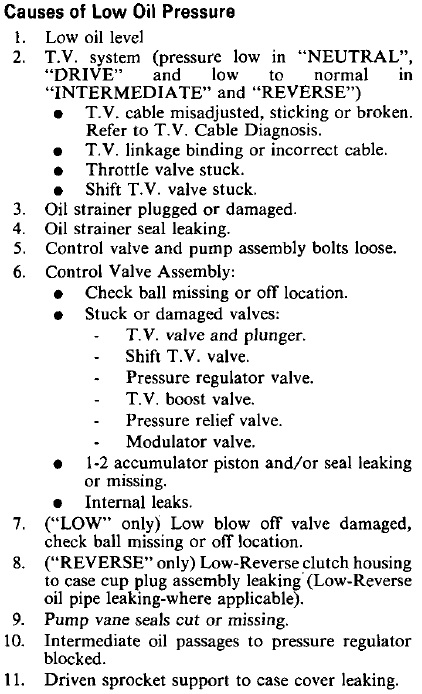

After pondering on this further, I'm thinking it has to be a seal that's leaking. Seems as the fluid heats up and becomes thinner, it's finding a way past a gasket and causing pressure loss. If it were a problem with the pressure regulator valve, I'd expect most pressures wouldn't be within spec when the trans. is cold. Only reverse appears to be down a significant amount when cold. Given that reverse is the gear with the highest pressure, it would likely amplify the leak problem. I now suspect one or more valve body bolts could be loose. Even though I used a 1/4" torque wrench to tighten them to factory specs, I'm questioning whether it's accurate.

Here's an excerpt from the service manual. I feel I can comfortably eliminate no. 1-4 & 7-10 as potential causes.

Will re-check the valve body bolts and whether my torque wrench is calibrated correctly.[This message has been edited by James_GT (edited 08-07-2022).]

|

|

|

OldsFiero

|

AUG 07, 04:55 PM

|

|

First thoughts from memory; separator plate gaskets reversed, loose bolts, boost valve sleeve retaining pin positioned incorrectly on sleeve grooves. When I get time I'll try to look at fluid charts to see if there is anything else. DO NOT put the car under high load conditions until you locate the problem.

Marc

|

|

|

James_GT

|

AUG 07, 08:08 PM

|

|

| quote | Originally posted by OldsFiero:

First thoughts from memory; separator plate gaskets reversed, loose bolts, boost valve sleeve retaining pin positioned incorrectly on sleeve grooves. When I get time I'll try to look at fluid charts to see if there is anything else. DO NOT put the car under high load conditions until you locate the problem. Int/Rev boost valve sleeve retaining pin is holding the sleeve in the correct spot.

Marc |

|

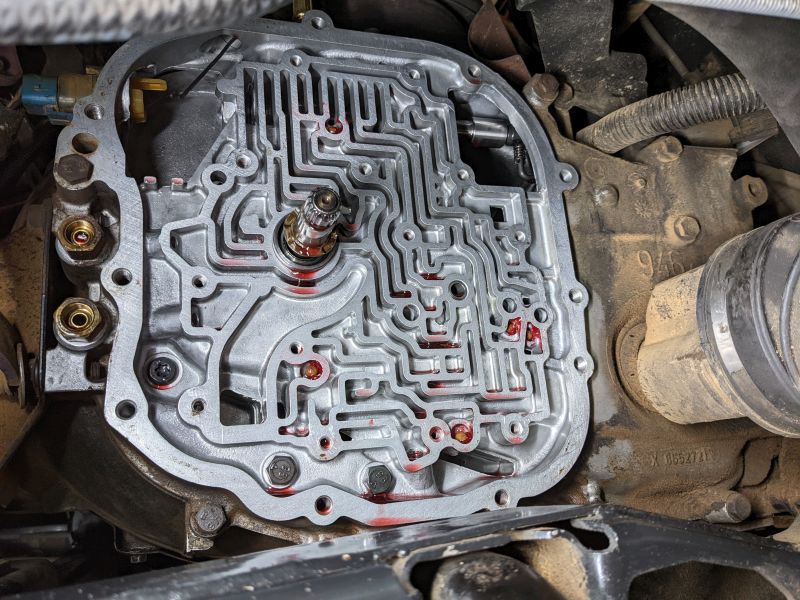

Thanks for your help, Marc. Separator plate gaskets can be interchanged on either side, can't they? As long as the holes line up they should be all good? This is how my valve body looked before it was reattached, with small amounts of grease holding the gaskets and check balls in place.

In Line Pressure Test #2 above, where there's a ~ symbol next to the PSI reading the pressure gauge needle is flickering and not holding steady. Also during warmup, with the trans. in Drive, it would fluctuate between 70 & 110 PSI. Settling at 75 PSI when warmed up.

Still leaning toward loose bolts being the cause. I've had the valve body off twice now and had the same result, even after changing the separator plate gasket. I tightened the long torx bolt (valve body to drive sprocket support) by hand, so maybe that's causing problems here.[This message has been edited by James_GT (edited 08-07-2022).]

|

|

|

OldsFiero

|

AUG 10, 06:59 AM

|

|

My bad. The VB gaskets are the same. I see that min line is OK even hot, so pump volume or leak is unlikely. You didn't mention whether lock up works or not. There is a bolt that goes through the auxiliary valve body that holds the bore plug and lock up control valve in place. If the plug is missing or the valve fell out when you took it apart, and was reinstalled backwards, the result would be no lock up and low line pressure.

You have very little pressure rise which indicates a TV / boost problem. After looking at hydraulics, I think a missing #6 check ball is likely the problem.

There are 5 check balls in the case cover. #6 is the uppermost one in a passage that connects to the manual valve. If it is missing, RNDL oil from the manual valve to the TV valve will leak into the detent circuit. Pretty sure it could cause your symptoms.

Hope this helps,

Marc

|

|

|

James_GT

|

AUG 12, 05:22 AM

|

|

| quote | Originally posted by OldsFiero:

My bad. The VB gaskets are the same. I see that min line is OK even hot, so pump volume or leak is unlikely. You didn't mention whether lock up works or not. There is a bolt that goes through the auxiliary valve body that holds the bore plug and lock up control valve in place. If the plug is missing or the valve fell out when you took it apart, and was reinstalled backwards, the result would be no lock up and low line pressure.

You have very little pressure rise which indicates a TV / boost problem. After looking at hydraulics, I think a missing #6 check ball is likely the problem.

There are 5 check balls in the case cover. #6 is the uppermost one in a passage that connects to the manual valve. If it is missing, RNDL oil from the manual valve to the TV valve will leak into the detent circuit. Pretty sure it could cause your symptoms.

Hope this helps,

Marc |

|

Thank you again, Marc. The lockup converter is working normally. Feels like it engages quicker than before the shift kit install.

That's a logical hydraulic diagnosis - though I'm fairly certain none of the check balls are out of place. I used a touch more grease to hold them in this time, ensuring all six wouldn't fall out while refitting the valve body. One other change I made during the shift kit install was to replace the steel check balls with Torlon, though I don't see how that would have any negative effects on the trans if they're the same size as stock (0.250").

I'll take another look at it over the weekend. If it's not a loose bolt(s) or a problem with the check balls, I may need to hand this over to a transmission shop. Don't really want to give up on it now, since it seems so close to success at this point.[This message has been edited by James_GT (edited 08-12-2022).]

|

|

|

Mike in Sydney

|

AUG 12, 07:16 AM

|

|

|

|

OldsFiero

|

AUG 12, 12:13 PM

|

|

This is a long shot. You mentioned holding the balls in place with grease. What kind? Approved stuff is Vaseline or TransJel. Since you are using plastic balls, if the grease didn't melt do to a short test drive, they may not be seating. Check for that on teardown.

I don't give up without a fight, so I'd like to help solve this. Lets revisit the TV and regulator valve train again. Did you remove the TV valve for cleaning? If so, check to make sure the retaining pin is between the two larger lands. Check the detent plunger sleeve pin location ( you removed it to put the bar from the kit inside the TV spring ). The pin goes in the narrow groove at the outer end of the detent sleeve. STV oil goes a lot of places in that valve train, so could likely be it.

Not likely, but check the STV spring to make sure it's in place and not broken.

In an '87, it would be hard to install the boost sleeve retainer incorrectly, but check the entire regulator valve train assembly again. This means checking the boost valve inside the sleeve to make sure it's not stuck and such.

Good luck,

Marc

|

|

|

James_GT

|

JAN 15, 08:36 PM

|

|

I haven't given in yet, though this will be my last attempt at solving the line pressure issue before taking it to a specialist. Had the valve body/oil pan off a few times now and still getting the same result.

IMO, internal leaks are the probable cause of my low pressure problem. Since this began, I have replaced the valve body gaskets, swapped torlon check balls back to the original steel type, replaced sealing rings and fitted a new cover gasket for the int. servo piston, as well as the filter and filter seal. I performed another pressure test after that, except this one was at 1,000 RPM instead of idle speed. The pressure gauge needle holds steady at lower pressures, but flickers at higher pressures. Maybe that's normal, but I thought it was worth noting in case it's a sign of an internal leak. Line pressure rises instantly when the T.V cable is pulled, though it won't go beyond 150 PSI in reverse when it's expected to be at 200+.

Factory Pressure Specs - 7CPC - @ 1000 RPM

-------- Min T.V -------- Max T.V

P ------- 66-74 ----------- 66-74

R ------ 117-129 -------- 232-258

N/D ---- 67-74 --------- 133-147

I/L ---- 114-126 ------- 114-126

Line Pressure Test #3 - Trans. Hot @ ~1000 RPM

-------- Min T.V -------- Max T.V

P --------- 70 -------------- 70

R -------- 110 ------------- 150

N/D ----- 70 -------------- 125

I -------- 110 -------------- 110

L --------- 95 -------------- 100

It's interesting how the readings are always just a few PSI below factory spec, except when it's at the lowest intended pressure of 70 PSI. Once it reaches the higher boosted pressure of 150+ PSI, the problem is exacerbated. That's leading me to believe it's an internal leak, which gets worse as pressure increases and the fluid thins out when it comes up to temperature. Another thing I've noticed is the pressure in intermediate (2nd) and low (1st) is meant to be identical, but is 10-20 PSI lower when low gear is selected. That may help pinpoint where pressure could be bleeding from.

So here's where I'm at. I suspect either the valve body isn't sealing properly against the case, or the modification to the lands on the pressure regulator valve are resulting in a significant loss of line pressure. I will be reverting back to an unmodified valve as soon as I find one. I now have a better quality torque wrench to tighten the valve body bolts, in case the inexpensive one was inaccurate. If it turns out to be anything beyond that, I'll take my Fiero to a shop for diagnosis.

@OldsFiero Thanks again for your help. The check balls are held in with multi-purpose L80 grease. It does melt easily when it comes into contact with ATF and there's no trace of it on teardown. I didn't remove the TV valve and it appears to be working normally, based on the pressure increase when pulling the TV cable out. Retaining pins are in the correct locations. I haven't touched the TV boost valve inside the sleeve yet. If it were stuck though, I'm not sure it would affect the low Min T.V pressures I'm seeing in I/L & Reverse.

@Mike in Sydney Thanks for the PM. Hopefully I'll be able to cruise up to Sydney and catch up with more Australia-based Fiero owners once this transmission is fixed.[This message has been edited by James_GT (edited 01-18-2023).]

|

|

|

OldsFiero

|

JAN 18, 11:22 AM

|

|

Hi James,

I'm not too concerned about grinding the PR valve. You would have to have a pretty good leak in the converter feed circuit for it to have much effect and you would have converter related complaints that you don't have.

You do need to look at the boost valve assembly for problems. It's been so long, I can't remember if it's possible to install the int/rev boost valve backwards and still have the bumper spring fit over the stem. If so, that would limit exhausting decrease oil to the pump slide. When the auxiliary valve body is off, look at the pump slide and priming spring carefully. Look for an obstacle that would keep the slide from moving all the way to the max position. Check for a broken priming spring. The spring is what actually moves the slide to max output. I know it worked ok before you got there, but everything can break sometime. Trust me, I can tell you more than one story of stuff like that happening to me over 50+ years of repairs.

Lower pressure in L and R could indicate a problem in the L/R clutch. Check the L/R apply tube for proper fit. There is an o-ring on top of the washer at the rear end of the tube. While you are there, use a rubber tip blow nozzle to air check the L/R clutch.

I would revisit the VB first.

Good luck,

Marc

|

|

|

|