|

| A retrofit for gen 1 headlight (Not a gen 2 swap) (Page 1/10) |

|

Dukesterpro

|

FEB 02, 03:25 PM

|

|

So I am powering through a capstone project for my degree.

What I came up with is a complete retrofit system for gen 1 Fiero headlights. That requires no modication's to the wiring harness of the Fiero, beyond the removal of a few relays. It utilizes the original gen 1 headlight motor housing, gears and armatures. (You will still need Rodney's gear set. But does away with the complex internal switch setup inside and includes a new brush holder assembly to replace the older white assembly that has the circuit breaker and disconnect assembly. It uses a custom circuit that's included with the kit that has a alternative by shockingly similar way of detecting headlight up and down conditions. The controller box also has accessory wires for a blink and wink function (left and right selectable) The circuit is made out of hyper common components and is end user repairable. I found the most common failure of the Gen 1 Headlight is simply the brush holder and the brushes. Along with the relays necessary to support the system. The armature is almost always serviceable.

Is this something the Fiero community would be interested in? Its running through course trials at the moment and I could have a few units ready to ship by the summer. (Price should be about 200 dollars for the complete drop in set). I currently have 10 Fiero's in my area with the kit installed and am gathering data regarding cold weather performance. (Negative F temperatures)

I just want to see if the desire for a gen one repair kit that doesn't need to cannibalize a 88 or 87 is there. If not I'm just going to enjoy my working headlights

Heres a quick teaser of the new brush holder, mind you they have already been produced and installed on a working 84, 85 and 86 Fiero.

Let me know if this is something you think you would want so I can determine if I will mass produce them after my class is concluded.[This message has been edited by Dukesterpro (edited 02-02-2023).]

|

|

|

fierofool

|

FEB 02, 06:17 PM

|

|

Something like this is badly needed. I am quickly running out of good limiter switches and we don't have many 87 and 88's to cannibalize. Had a run on limiter switches in the last couple of months.

Some questions about your design function.

How does it interrupt the power to the motor at the end of travel? Does it still use contact point sets?

Is there any kind of interrupter that replaces the thermal switch in the event your design fails to shut off power at the end of travel?

Does it eliminate the Isolation Relay? Motor relays are still available but the Isolation Relay is only available as a used piece.

|

|

|

Dukesterpro

|

FEB 02, 11:49 PM

|

|

1. Since the way the headlight detects up and down is crucial to the patent it was recommended by my professor that I file, I can't divulge precisely how the headlight detects its up and down position. I will say however retrofit does not have any mechanical, optical, or sonic limiting device.

2. The last case of failure is a simple fusible link. However, in the case of failure, my design utilizes a default off state, meaning that if something fails or detection isn't found within a set time limit it will ALWAYS cut power. There are effectively 3 phases of protection. First in the operation code, then the 6amp fusible link, and finally the 8 Amp max of the power bridge on the controller meaning the motor and car's wiring is always going to be safe from shorts or fails. Interestingly enough the headlight can detect intrusions or interrupts and will also know to cut power if say, the headlight pot fails and jams or something interferes with the rising of the headlight (pretty girl sitting on the hood, if only) without burning up a fusible link or the controller.

3. And my favorite part. It completely eliminates all relays on the headlight motor section of the headlights. Only requiring fused constant voltage and the on and off signal from the headlight switch). The motor relay and isolation relays are removed during the installation.

extras: Something I should also mention is that the kit will also allow for a delay on the headlight if so desired. In which the headlight will not turn on until the bucket has fully raised or is interrupted. This is not required to use the kit, however. Five of the Fieros that I have running trials use the delay on the headlight the owners are apparently quite happy with its operation.

I also considered making a run on a replacement limit switch that would direct swap the original with a more reliable digital circuit breaker and optical instead of mechanical switches. But deemed the idea somewhat pointless as the failure of the isolation relay dooms the headlight system anyway. Down with the isolation relay!

I eagerly await your feedback,

George

|

|

|

Wichita

|

FEB 03, 05:51 AM

|

|

My 85 headlights are operational and have Rodney's kit already. But I would definitely get your mod for sure. Anything to modernize them is a plus. $200 is a very fair price for what you are describing as this retrofit kit.

I'm in for a set when ever you are in production.

|

|

|

Dukesterpro

|

FEB 03, 10:52 AM

|

|

Noted,

The last part of my project is optimization, I am hoping to get the price down even further.

Thanks for the feedback!

|

|

|

ArthurPeale

|

FEB 03, 05:36 PM

|

|

|

continued development projects for our beloved Fieros are always something I follow eagerly. I'd definitely like to know more - got any more photos, of the bracket, of the PCB ?

|

|

|

Dukesterpro

|

FEB 03, 06:27 PM

|

|

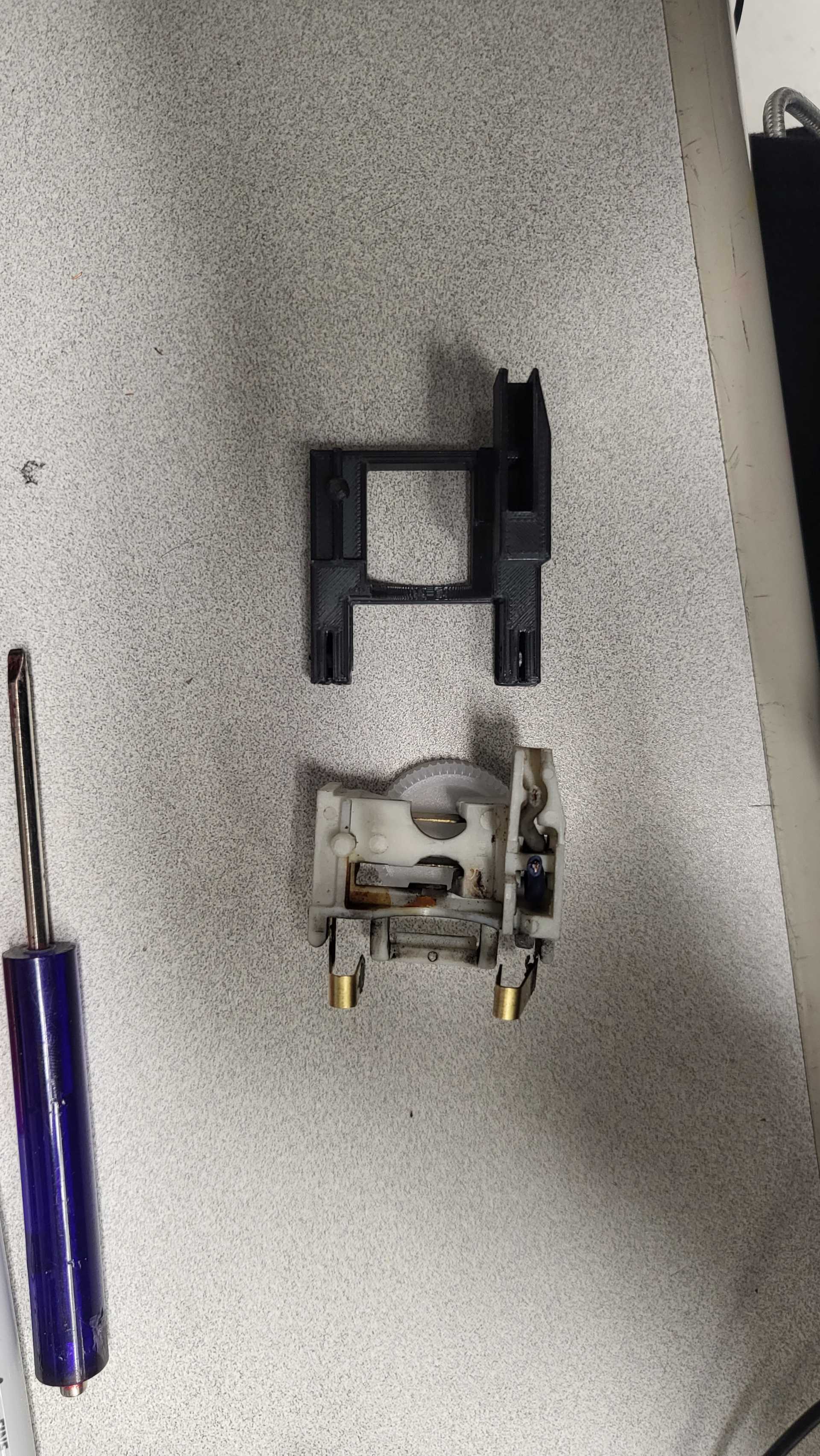

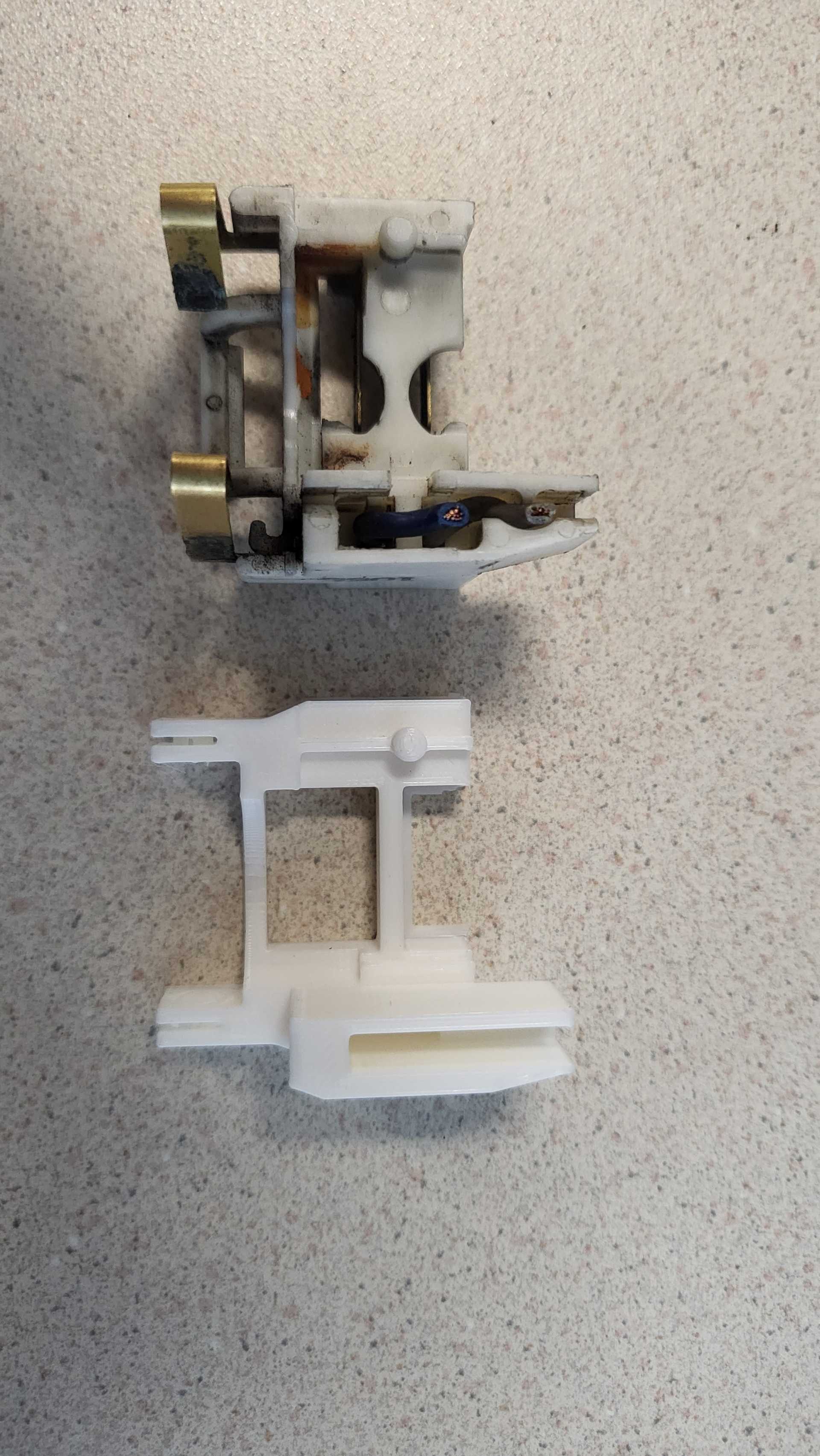

Here's a quick pic of the 3d printed brush assembly housing compared to a OEM brush housing. We are using ABS filament followed by a Acetone bath finish and a liquid nitrogen bath for strengthening. There is two designs of this housing circulation. This is the one I assume to be the weaker of the two, but only the trial period will tell. They have bolt on, removable brush arms, because I hate the way you had to attach the brushes on the old one. Brush wear for the time being will still be an issue, but my plan is to provide replacement brush arms that just bolt in instead of having to use the glue method that Rodney's brushes have but only time will tell. I am also experimenting with some alternative brushes, but they seem to be far too hard and eat into the armature. Oh well, can't win them all.

When the test Fiero's come back into town on February 25th, I will post a full video of the headlight system in action.

Further. An most importantly. I may not be always be able to provide kits for sale, the last thing I want to have happen is for me to fall away from the Fiero community and the tech to be lost behind a wall of red tape and custom PCBs. The control box will be made from entirely premade and readily available parts. The main PCB is standard Arduino Uno (With hard soldered components and waterproof coating, not just an Arduino taped to a box). The other components will be announced when the kit does go up for sale. But are readily available on amazon. So I ever disappear you will be able to purchase replacement components on the open market. No proprietary parts.

I'm sure many will just reverse engineer my kit and make there own. But its more important to me that the Fiero community have a permanent fix to the headlight problem, than to make an extra few hundred bucks. The only reason I'm considering pursuing the patent on the idea if it works out. (I don't believe it will qualify but my instructor seems confident) is to prevent blatant Chinese copycats from stealing my work and slapping it on amazon for pennies on the dollar.

I await further feedback,

George

|

|

|

Dukesterpro

|

FEB 06, 02:32 PM

|

|

Looks like we had a few failure in the field, I cooked up a mkII brush holder design and am cycling a few into circulation now.

New brush holder braces against the housing all the way across the gap to prevent rocking and rotating.

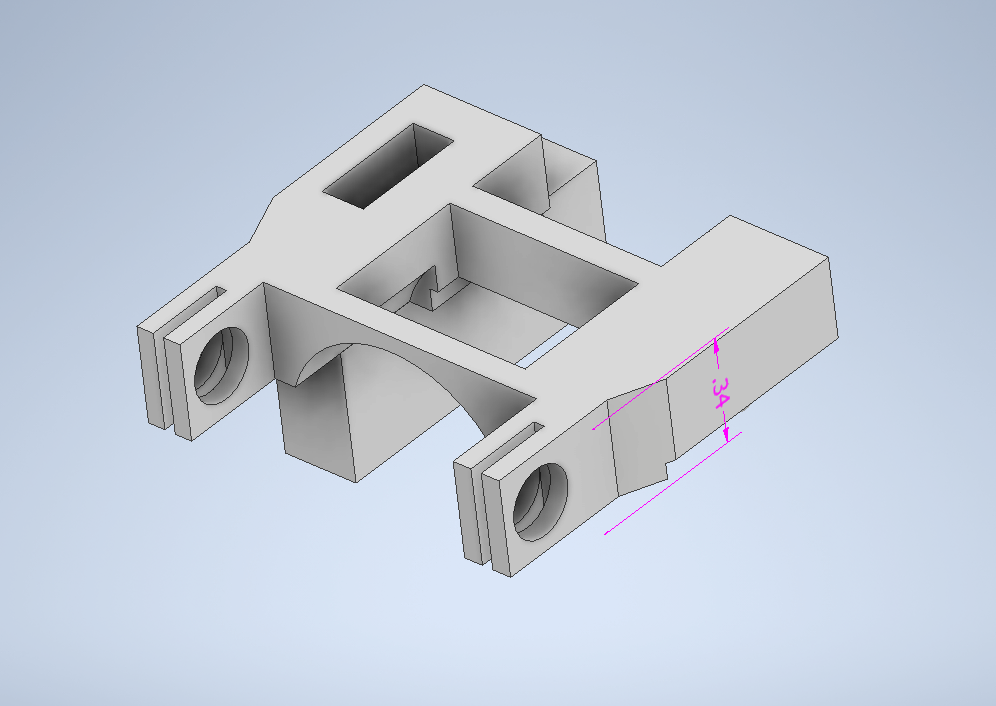

Here's a pic of the new design!

[This message has been edited by Dukesterpro (edited 02-06-2023).]

|

|

|

Dennis LaGrua

|

FEB 06, 06:49 PM

|

|

|

Looking good. I don't believe you will have to worry about somebody copying that design. There's a market but not a big enough market to tool up for another headlight motor control system. ------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

Steven Snyder

|

FEB 07, 04:40 AM

|

|

Cool to see some development going on to improve these ancient systems! I'm seeing more and more 3D printing tech used to restore and improve our cars. This is such a great application for it. I've also been designing and printing Fiero-related parts for the last couple years.

What is the material for the original brush holder? Is it ABS? I expected it to be nylon, perhaps even glass-fiber reinforced. There should be a material code like "ABS" or "PA66" molded into the part so you can tell.

| quote | Originally posted by Dukesterpro:

The only reason I'm considering pursuing the patent on the idea if it works out. (I don't believe it will qualify but my instructor seems confident) is to prevent blatant Chinese copycats from stealing my work and slapping it on amazon for pennies on the dollar.

|

|

A patent publicly discloses the method you use. This can make it very easy for someone to copy. In fact, for your patent to be accepted one of the requirements is that your public disclosure includes enough detail that someone sufficiently experienced in the art can reproduce it.

If the technique is not easy for someone else to discover or reverse engineer, it might be better to keep it as a trade secret -- meaning to never disclose it. That means no patent so it's up to you to protect the details of the invention from getting out.

Once someone copies your invention you have to take them to court (with your money) to prove they are violating your patent. Taking down foreign copycats for violating your US patent is expensive, difficult, or impossible. The cost of the initial patent application and attorney fees is probably more than you can make for selling these parts for Fieros. If your invention has applications beyond Fiero headlights, that may maket its worth pursuing a patent for, but you should call a patent attorney for consultation to understand the upfront and continuing costs for securing and maintaing patents.[This message has been edited by Steven Snyder (edited 02-07-2023).]

|

|

|

|