|

| ISO: Chop top advice. (Page 1/1) |

|

Chris Hodson

|

FEB 08, 02:36 PM

|

|

I've probably scanned every chop-top related thread on here and a few other forums. I'm looking for tips and tricks, maybe specific measurements if anyone cares to provide them, & advice from people who have completed a chop. What have you learned

Before anyone asks, my background qualifies me to complete the modification, and I know Archie offers kits. Come to think of it, if anyone has one of those rear window templates laying around I would buy it from you. That's the one thing that would help me out the most!

I'm not concerned with side windows just yet... maybe ever. I am interested in having a conversation with the few people here who have somehow finagled their window tracks to accommodate the new geometry with a stock window. I can see it in my head how it would kind of work but I'm still having trouble processing the idea. Probably because with what I want to do and what I already know....its just not an option.

I took the rear clip apart to do a fast back swap and I can't not put it back together without chopping it. If you have been here a while you have probably seen my car.

As is sits right now I have the top of the car disassembled along with the interior. The windshield is out and I managed to get the rear glass out without breaking it. I'm about to clean off the seam sealer so I can get to the spot welds.

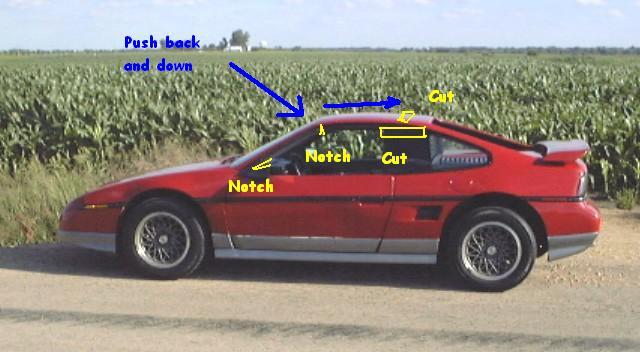

This is over simplified but seems like the best way to go about this is to weld in some supports to the car doesn't warp. Notch the A pillar in a few spots, take apart the rear part of the roof, maybe slide it into itself, cut the B pillars from the bottom of the rear window edges to about the bottom of where the door seal tracks stop. Pie cut the top inner sections of the B pillars to allow it to spread out. Open up the bottom of the B pillars and push the top portion in ~3.75" (or just cut and reweld?).

I'm looking forward to hearing from you guys. Thanks!

|

|

|

82-T/A [At Work]

|

FEB 08, 02:52 PM

|

|

| quote | Originally posted by Chris Hodson:

Before anyone asks, my background qualifies me to complete the modification...

|

|

I have no advice to give, but I caught on this. There is nothing I hate more, than when I post on a message board, and the first response I get from everyone is to have a professional do it. Hahah... it's like, that's not what I asked... I asked how do I do it, not that I need you to tell me that I can't!

|

|

|

Chris Hodson

|

FEB 08, 08:00 PM

|

|

|

|

Chris Hodson

|

FEB 08, 11:55 PM

|

|

I was wrong. I did NOT go through every thread. I totally forgot about Orville. He has some great information as well. I'm going to copy and past a bit here so I don't forget.

In regard to using this as a starting point. https://www.summitracing.co...del/camaro/year/1982

----------------------------

Hi guys,

To answer your questions: On my chop the angles of the "A" and "B" pillars toward center are stock.

I think Archies angle inward more than stock because laying back the stock windshield narrows the roof.

That's why his windows are curved inward 3". I'm not sure if that's for each window or total but I suppose

it's total. In each case this lexan will work because it has the same curves vertically and horizontally as

the stock fiero glass. Where the curve differs however is in the portion bellow the dew wipes that attaches

to the raising/lowering mechanism. What I did was position/fasten the cut-to-size lexan to the edge of a

table with the portion just below the dew wipe along the edge of the table. Then I heated the lexan along

this edge with a heat gun and carefully curved it downward by pushing with a piece of 2x4 until it had the

same curve in this area as the stock glass. I'm not sure but I think this procedure would also work for

Archie's chop, just have to bend it a little more.

Couple more things: The black material on top of the lexan in the pic is the template for the cut down

window. Also, this lexan is 3/16" thick which I think will work although in my other chop I used 1/4".

The stock thickness is about 7/32".

Orville

--------

I would need to somehow confirm that its curved, overwise I would just cut it and shape it myself.

|

|

|

Chris Hodson

|

FEB 09, 12:34 AM

|

|

A collection of inspiration.

|

|

|

|