|

| 3800 swap- Dogbone question (Page 1/2) |

|

cam-a-lot

|

MAY 26, 07:17 AM

|

|

Hello

The previous owner of my car did a pretty nice job on the swap, but went without a dogbone.

He used a purple reign mount, and an additional cradle mount was custom made

I would like to reduce the amount of vibration being transferred from the engine into the frame of the car, so I am planning to install a dogbone with rubber bushings to reduce any possible engine movement.

I know that there are a lot of people here who have swapped 3800 motors. In particlar, what parts from the Fiero and what parts from the donor car were used to make a good, solid dog bone connection between the two? Did you re-use the donor car bracket?

Would appreciate some opinions on this

thnaks

|

|

|

Frenchrafe

|

MAY 26, 10:57 AM

|

|

Sorry, can't help you with the upper torque strut config.

I use two "dog bones"; one on each side of the engine block.

They are at roughly 45° off the horizontal and are fixed to very simple brackets/extensions welded to the subframe.

And yes, the vibration is not great at idle to 1500rpm.

After 2000rpm or above it clears but the cabin remains noisy!

But there again, I track my Fiero. So I live with it!😉------------------

"Turbo Slug" - '87 Fiero GT. 3800 turbo. - The fastest Fiero in France! @turboslugfiero

https://youtu.be/c4Cu7_2OgYc

|

|

|

olejoedad

|

MAY 27, 08:50 AM

|

|

No help from me either, none of the dozens of swaps we have done have used a dogbone.

Four corner mounts to the subframe to prevent any movement of the drivetrain and to keep the top looking uncluttered.

|

|

|

pmbrunelle

|

MAY 27, 09:27 AM

|

|

You cannot only add a dogbone; you must also remove/soften the mounts which are currently transmitting excess vibration.

I suppose that you should look around for rubber dogbones with hollowed-out bushings; the kind of bushing where the steel sleeve is mostly held by air, but when submitted to high force, the rubber deflects, the airspace disappears, and then it's solid rubber-to-rubber contact. A progressive-rate bushing.

Whatever mounts you add need to go to a strong point on the Fiero.

Some of the factory 3800 cars have dogbones going to their front crossmembers; this sort of setup cannot be used on the Fiero, as there is no corresponding strong point.

How feasible is it to destroke the 3800 to a 3300? The less the pistons move, the less vibration you have.[This message has been edited by pmbrunelle (edited 05-27-2023).]

|

|

|

Spoon

|

MAY 28, 07:39 PM

|

|

| quote | Originally posted by pmbrunelle:

Whatever mounts you add need to go to a strong point on the Fiero.

Some of the factory 3800 cars have dogbones going to their front crossmembers; this sort of setup cannot be used on the Fiero, as there is no corresponding strong point

|

|

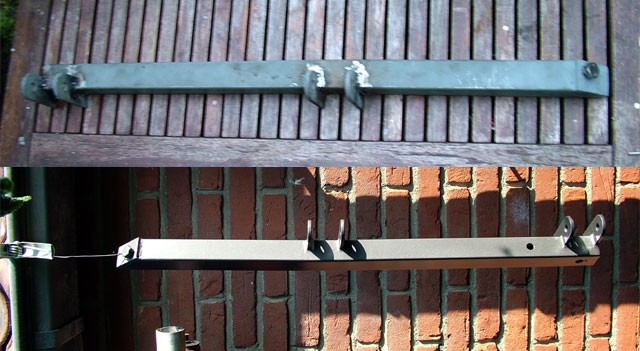

I swapped out a 2000 GTP 3800SC that had dual dogbones on the front radiator support. Dropped it in the Fiero with 1 existing support in the usual place and I connected the other one to the same support panel. My Dogbones were poly but I use rubber on the trans & engine mount. No vibration whatsoever and its the 4 speed trans. No flexing or bending so far. Much better than just a single bone since each is sharing 50% of the load.

Pic is my setup.

Right side Dogbone is custom made by member on Pennocks. Since the swap I've been trying to find another.

Spoon

------------------

"Kilgore Trout once wrote a short story which was a dialogue between two pieces of yeast. They were discussing the possible purposes of life as they ate sugar and suffocated in their own excrement. Because of their limited intelligence, they never came close to guessing that they were making champagne." - Kurt Vonnegut [This message has been edited by Spoon (edited 05-28-2023).]

|

|

|

pmbrunelle

|

MAY 28, 11:48 PM

|

|

The middle of the trunk wall is a flexible area, so load sharing between dogbones is probably 90% strut tower dogbone, 10% trunk wall dogbone (not contributing in a meaningful way).

Because most of the load is taken up by the strut tower dogbone, I think the trunk wall was spared from being flexed/bent.

Unless the trunk wall beam is heavily beefed up (similar to GTP radiator support) or triangulated, I advise against a trunk wall dobgone.

|

|

|

cam-a-lot

|

MAY 29, 05:31 AM

|

|

|

Great info-. thanks everyone

|

|

|

reinhart

|

MAY 29, 05:33 PM

|

|

| quote | Originally posted by pmbrunelle:

The middle of the trunk wall is a flexible area, so load sharing between dogbones is probably 90% strut tower dogbone, 10% trunk wall dogbone (not contributing in a meaningful way).

Because most of the load is taken up by the strut tower dogbone, I think the trunk wall was spared from being flexed/bent.

Unless the trunk wall beam is heavily beefed up (similar to GTP radiator support) or triangulated, I advise against a trunk wall dobgone. |

|

Good point about the trunk wall being weak sheet metal. It probably would make sense to weld a small 1x1 box bar across the wall from the original dogbone tower to the left strut tower along the trunk wall, if you're going to employ a dual setup. If there's no room there, you could put the support bar inside the trunk behind the carpet.

It seems to me like one would be enough to really tighten it up, since many are running without a single bone. Perhaps start with one and video record the engine compartment while driving aggressively and see if the engine is moving around under hard acceleraion/shifting/etc.[This message has been edited by reinhart (edited 05-29-2023).]

|

|

|

Spoon

|

MAY 29, 05:38 PM

|

|

| quote | Originally posted by pmbrunelle:

Unless the trunk wall beam is heavily beefed up (similar to GTP radiator support) or triangulated, I advise against a trunk wall dobgone. |

|

I see your point now. Thanks for your info. Perhaps a blade of armor across the trunk wall would help some.

And Cam-A-Lot, pardon the hijack.

Spoon

------------------

"Kilgore Trout once wrote a short story which was a dialogue between two pieces of yeast. They were discussing the possible purposes of life as they ate sugar and suffocated in their own excrement. Because of their limited intelligence, they never came close to guessing that they were making champagne." - Kurt Vonnegut [This message has been edited by Spoon (edited 05-29-2023).]

|

|

|

Fie Ro

|

MAY 29, 06:03 PM

|

|

| quote | Originally posted by reinhart:

Good point about the trunk wall being weak sheet metal. It probably would make sense to weld a small 1x1 box bar across the wall from the original dogbone tower to the left strut tower along the trunk wall, if you're going to employ a dual setup. If there's no room there, you could put the support bar inside the trunk behind the carpet.

It seems to me like one would be enough to really tighten it up, since many are running without a single bone. Perhaps start with one and video record the engine compartment while driving aggressively and see if the engine is moving around under hard acceleraion/shifting/etc.

|

|

|

|

|

|