|

| Engine Support Question (Page 1/1) |

|

OldGuyinaGT

|

JUL 06, 12:37 AM

|

|

I have an 88 GT - stock V6 and THC125. I've been looking for a way to support the engine while I change the oil pan gasket (and eventually other service). After looking at all the alternatives I could find, I decided it would be best (for me) to use the j-tools necessary to do it like in the FSM.

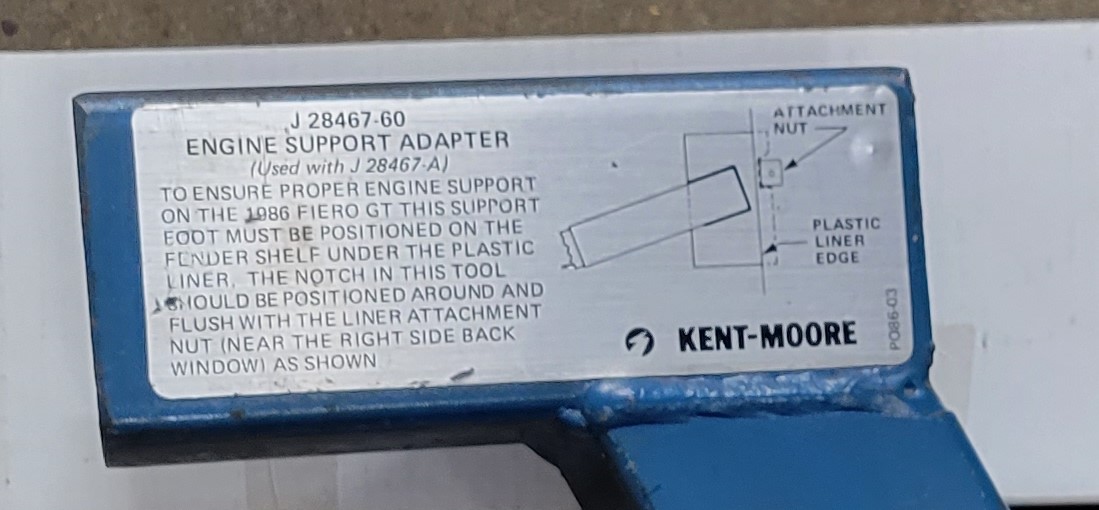

I bought the appropriate pieces as shown, but the piece shown on the right side (J-28764-4) won't sit down to securely support that end of the fixture, at least on a GT. Then I came across this:

J28764-60, which is listed as specific to the 1986 Fiero GT, right down to the text and diagram on the label. Perfect! All set, right?

Not so fast. This support won't fit here:

Is the 88 different from the 86 here? A local buddy of mine has an 88 GT and it looks identical to mine here. Am I positioning this correctly? Any thoughts on how to make this work?

|

|

|

Patrick

|

JUL 06, 12:53 AM

|

|

Is it "just" the wiring harness that's preventing that support foot from going where the diagram says to position it? If so, I wonder if you temporarily remove that plastic trim piece, if maybe you can somewhat relocate the route of that harness.  [This message has been edited by Patrick (edited 07-06-2023).]

|

|

|

jelly2m8

|

JUL 06, 03:40 AM

|

|

I supported many a 2.8 with it's jack under the the harmonic balancer from the engine cradle while doing an oil pan, Never had a single one blow up in 31 years.

|

|

|

Dennis LaGrua

|

JUL 06, 10:30 AM

|

|

|

My technique required a few more steps but can't say that they are needed in every case. What I did was to support the engine using a small square of plywood and a floor jack not putting excessive pressure on it. Then I removed the front engine mount and the mount bracket while placing a 10" piece of 2 x 4 on the frame and under the harmonic balancer to keep the engine supported. That exposes all oil pan bolts. This might be similar to what jelly2m8 does but he is a pro mechanic and probably does it in less steps. I did this years ago when I had a 2.8L and the garage didn't have the 2 post lift and the engine crane. Today I would probably do it differently. ------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

OldGuyinaGT

|

JUL 06, 11:20 AM

|

|

| quote | | Is it "just" the wiring harness that's preventing that support foot from going where the diagram says to position it? If so, I wonder if you temporarily remove that plastic trim piece, if maybe you can somewhat relocate the route of that harness. |

|

No; the harness is in the way, too, but mostly out of view in this photo is some sort of high density foam material, perhaps isolating the body panel from the frame? Even if I can relocate the harness, this material prevents me from putting the support under the plastic very far at all (some is visible in the photo, forward of the liner attachment), and nowhere near "flush with the liner attachment nut" as stated on the label.

I am aware of the method of supporting the engine under the harmonic balancer, but I didn't want to do that because of other posts that pointed out the excessive force this places on the balancer ring and the polymer of the balancer assembly. I think my balancer is original, but it is in very good condition, so and I didn't want to risk damaging it. Besides, shouldn't this support work?

|

|

|

fieroguru

|

JUL 06, 09:59 PM

|

|

That area is the same for all Fieros. I would remove the inner plastic panel. That will make it easy to slide the harness away and you can push the foam out of your way.

I just made my own:

| quote | Originally posted by fieroguru:

I lost a few hours today making this engine support bar in preparation of removing the transmission. The brackets on the side have a bolt that locks into a hole in the strut tower and there is a leg on the other end that rests on the upper frame rail. The cross bar bolts to these side brackets and once tight everything is locked into place. I wrapped several areas of the side brackets with 5 wraps of electrical tape to help reduce chances of scratching the paint.

|

|

|

|

|

OldGuyinaGT

|

JUL 07, 01:25 AM

|

|

Looks like the only way to do this will be to remove the plastic liner and rearrange things, as you described.

By the way,I would certainly have copied your support - if I had ever learned to weld.

|

|

|

Dennis LaGrua

|

JUL 08, 04:17 PM

|

|

| quote | Originally posted by OldGuyinaGT:

I am aware of the method of supporting the engine under the harmonic balancer, but I didn't want to do that because of other posts that pointed out the excessive force this places on the balancer ring and the polymer of the balancer assembly. I think my balancer is original, but it is in very good condition, so and I didn't want to risk damaging it. Besides, shouldn't this support work? |

|

I believe that if you lower the engine down on the balancer carefully and support it with a piece of 2 x 4 on the cradle there will not be a problem. I've done this a few times and never had an issue but if the balancer is original 30 + years old I would have concerns.------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

|