|

| Why are there holes in V6 pistons tops ? (Page 1/3) |

|

StockGT

|

AUG 13, 06:03 PM

|

|

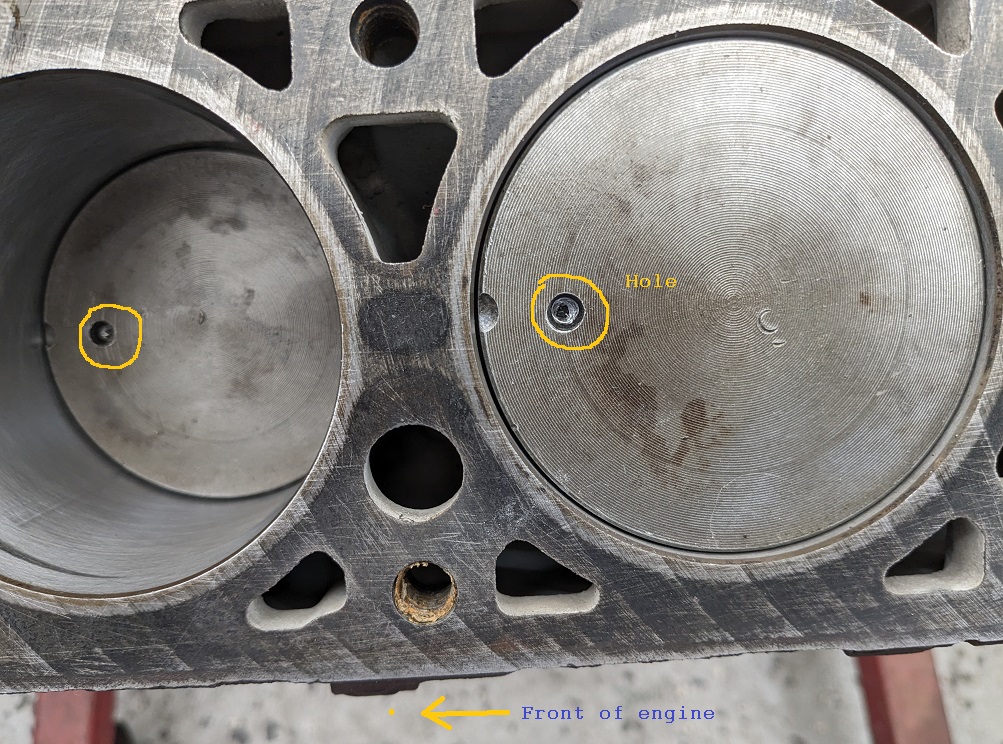

Looking at a stock 2.8L V6 that came back from Hot tank cleaning and I noiticed a small hole in each piston top.

The small holes appear to be plugged.

Looking at a second block that had not been cleaned, holes were visible on some of the pistons, that had less carbon buildup on the piston top.

Are the holes used in the manufacturing process, or the engine assembly ?

|

|

|

IMSA GT

|

AUG 13, 06:36 PM

|

|

|

I never noticed that. Interesting. [This message has been edited by IMSA GT (edited 08-13-2023).]

|

|

|

PhatMax

|

AUG 13, 07:05 PM

|

|

My 85 has those same holes.

180k miles…

|

|

|

CSM842M4

|

AUG 13, 07:14 PM

|

|

|

If the hole goes all the way into the piston ring groove, it's to provide pressure to the back side of the ring, pushing it outward against the cylinder wall to improve sealing. If it doesn't connect to the groove, somebody else will have to provide the correct answer...

|

|

|

Raydar

|

AUG 13, 10:49 PM

|

|

|

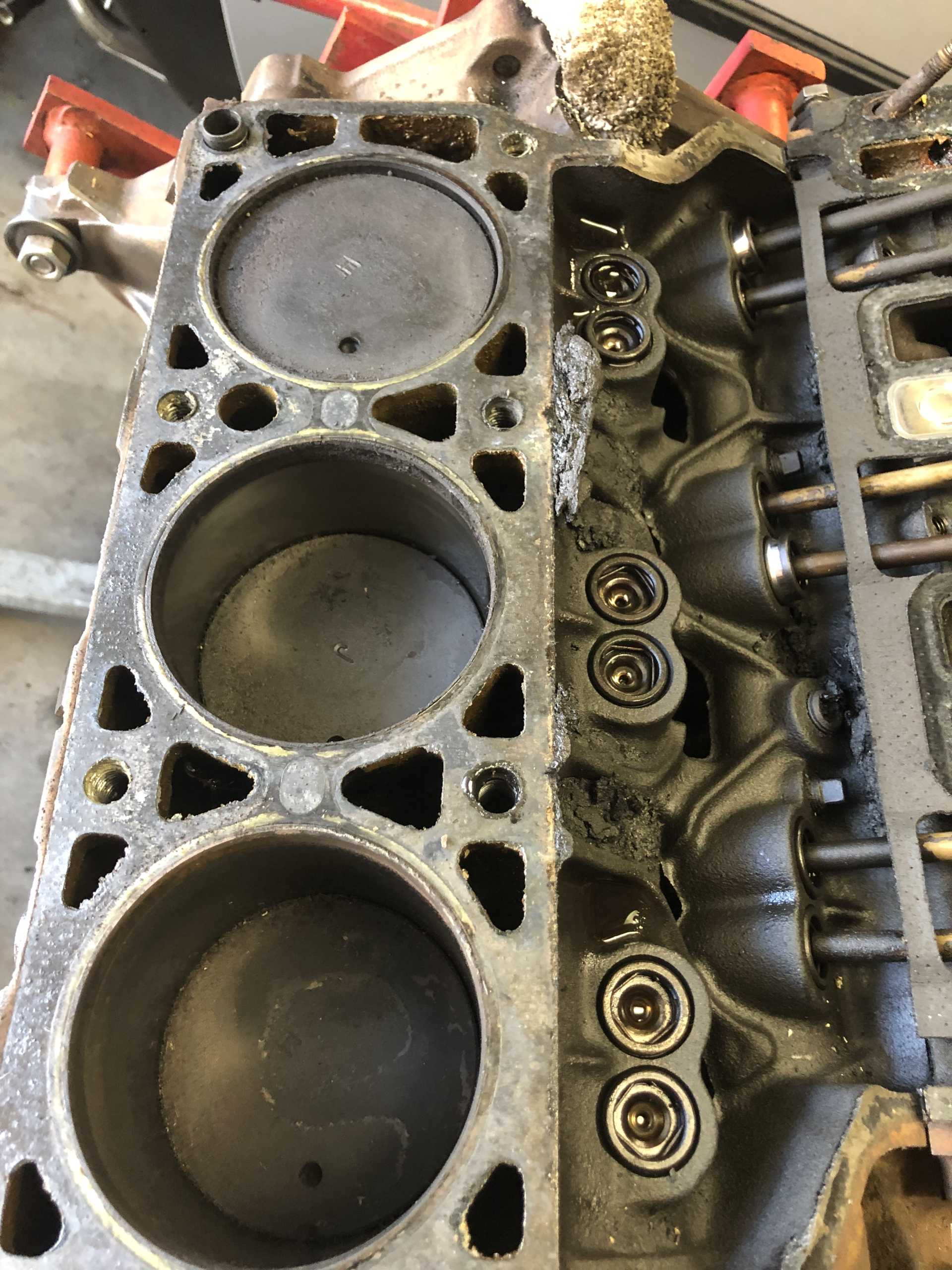

Interesting. I've never seen/noticed those, either. But I've never taken the heads off of a 2.8. Only 3.4s.

|

|

|

pmbrunelle

|

AUG 13, 11:18 PM

|

|

When the rod/piston assembly was inserted into the engine block at the factory, how would the assembly have been oriented correctly so the connecting rod opening would be parallel with the crankshaft throw?

That hole looks like it would be really useful to clock the assembly just prior to insertion into the engine block.

I don't know, it's just an idea.

There were perhaps other steps which required clocking the piston, such as when pressing in the piston pin.

********************************************************************************

I don't remember seeing holes like that when I took apart my 85 SE's engine.[This message has been edited by pmbrunelle (edited 08-13-2023).]

|

|

|

olejoedad

|

AUG 14, 08:14 AM

|

|

The holes serve two purposes.....

Pressure for the top compression ring

The hole faces the timing chain end of the engine to ensure proper crankshaft journal filet clearance

|

|

|

82-T/A [At Work]

|

AUG 14, 09:09 AM

|

|

When I disassembled my 87 Fiero engine, it didn't have any of these holes in it. It DID in fact though have that little notch on the end (like yours does also, on the same side you have the hole oriented).

I'm not disagreeing with everyone here, but my initial thought is that perhaps this is to equalize compression. If you're curious, I would measure depth of the hole to see if they are consistent. It might just be a way for them to increase or lower compression. Remember that at the time these engines were made, there was a Federal law that mandated engine compression. I can't remember which one it was, and which specific year... but I think it was some point in 1973 or 1974. It was mandated BEFORE catalytic converters came on the scene (which I think was 1975?). Essentially though, engines had something like 10 to 11:1 compression ratios, even higher... prior to the Federal mandate. It was based both on emissions and a lobby from the Insurance industry. Lowering the compression of these big engines had a dramatic effect on engine performance. I believe the requirement was that you couldn't produce anything above 8.5:1 in a consumer vehicle, but more was allowed if it was a "Non-Road" vehicle (which exempted the military and low-production performance vehicles). At some point in the early 80s, it was allowed to jump up to 8.9:1 ratio, and then I think they just eliminated it all together. Lowering the compression also results in lower temperatures due to a decrease in pressure, which results in less NOx.

My guess is that this was to ensure those pistons matched the legal requirement.

|

|

|

Dukesterpro

|

AUG 14, 09:12 AM

|

|

assembly indicators

My duke has notches on the edge to orient the pistons the correct way during assembly. Scared the bejesus out of me the first time I did a head gasket.

|

|

|

Raydar

|

AUG 14, 10:02 AM

|

|

| quote | Originally posted by Dukesterpro:

assembly indicators

My duke has notches on the edge to orient the pistons the correct way during assembly. Scared the bejesus out of me the first time I did a head gasket.

|

|

True. Lots of pistons have the notch on the "front" edge. These pistons have the hole, but also have the notch.

I wonder if they are supposed to be "ported through" to the ring groove, as someone else speculated. That seems like the most plausible explanation to me.

If someone has one of those pistons out of the block, it would be easy to connect an air gun to the hole, and see if pressure comes out in the ring groove.

TLDR; I don't know. Have never seen it.

Edit - I have seen pistons with tiny holes drilled around the perimeter of the crown, down into the gap where the compression ring lives. But this?  [This message has been edited by Raydar (edited 08-15-2023).]

|

|

|

|