|

| V6/60 head bolts... same for 3.4 as they are for 2.8? (Page 1/3) |

|

82-T/A [At Work]

|

MAY 23, 08:06 PM

|

|

I know I can't re-use the old cyl head bolts, so I need to order a set of cyl head bolts, specifically for my 3.4 swap into my Fiero. I'd prefer to just order a set of new factory 2.8 cyl head bolts... is that OK? Or should I be ordering them for a 93-95 Camaro / Firebird (from which this motor came)?

Second question... when ordering a head gasket set... do I order a head gasket for a 3.4 Camaro / Firebird, or a 2.8 Pontiac Fiero (or is there even a difference)? I'll be using heads that came from a 2.8 Fiero onto my 3.4 engine.

Thank you!

|

|

|

1985 Fiero GT

|

MAY 24, 01:08 AM

|

|

| quote | Originally posted by 82-T/A [At Work]:

I know I can't re-use the old cyl head bolts, so I need to order a set of cyl head bolts, specifically for my 3.4 swap into my Fiero. I'd prefer to just order a set of new factory 2.8 cyl head bolts... is that OK? Or should I be ordering them for a 93-95 Camaro / Firebird (from which this motor came)?

Second question... when ordering a head gasket set... do I order a head gasket for a 3.4 Camaro / Firebird, or a 2.8 Pontiac Fiero (or is there even a difference)? I'll be using heads that came from a 2.8 Fiero onto my 3.4 engine.

Thank you! |

|

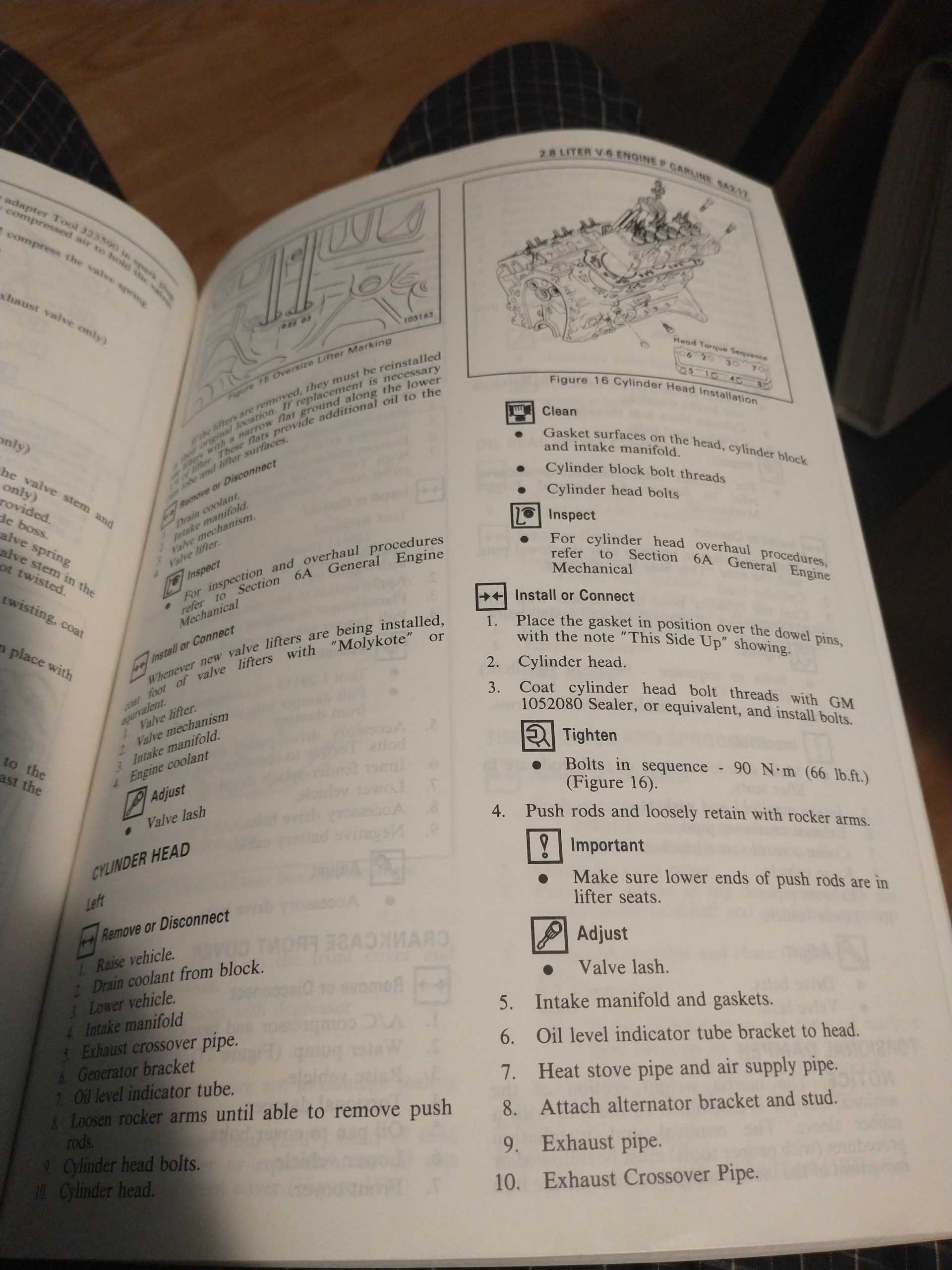

I don't know, I've read places that the original head bolts are reusable and not torque to yield, but replacements are, the factory service manual doesn't say to replace them, it does say to clean them, so that might indicate they are "reusable". I'm getting new fel pro bolts for mine, but it is interesting. I wonder if the torquing instructions are different for the TTY bolts vs the factory originals.

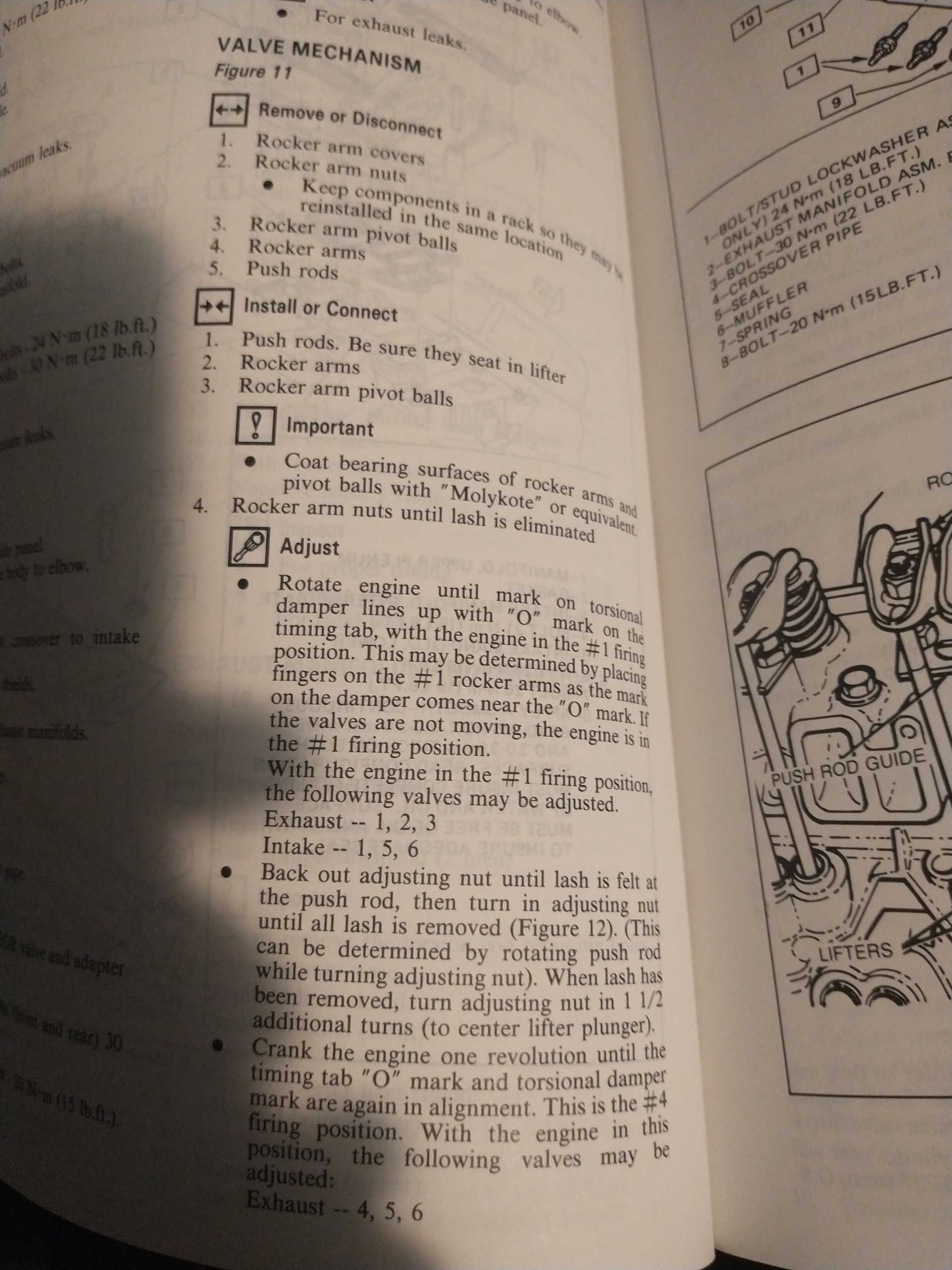

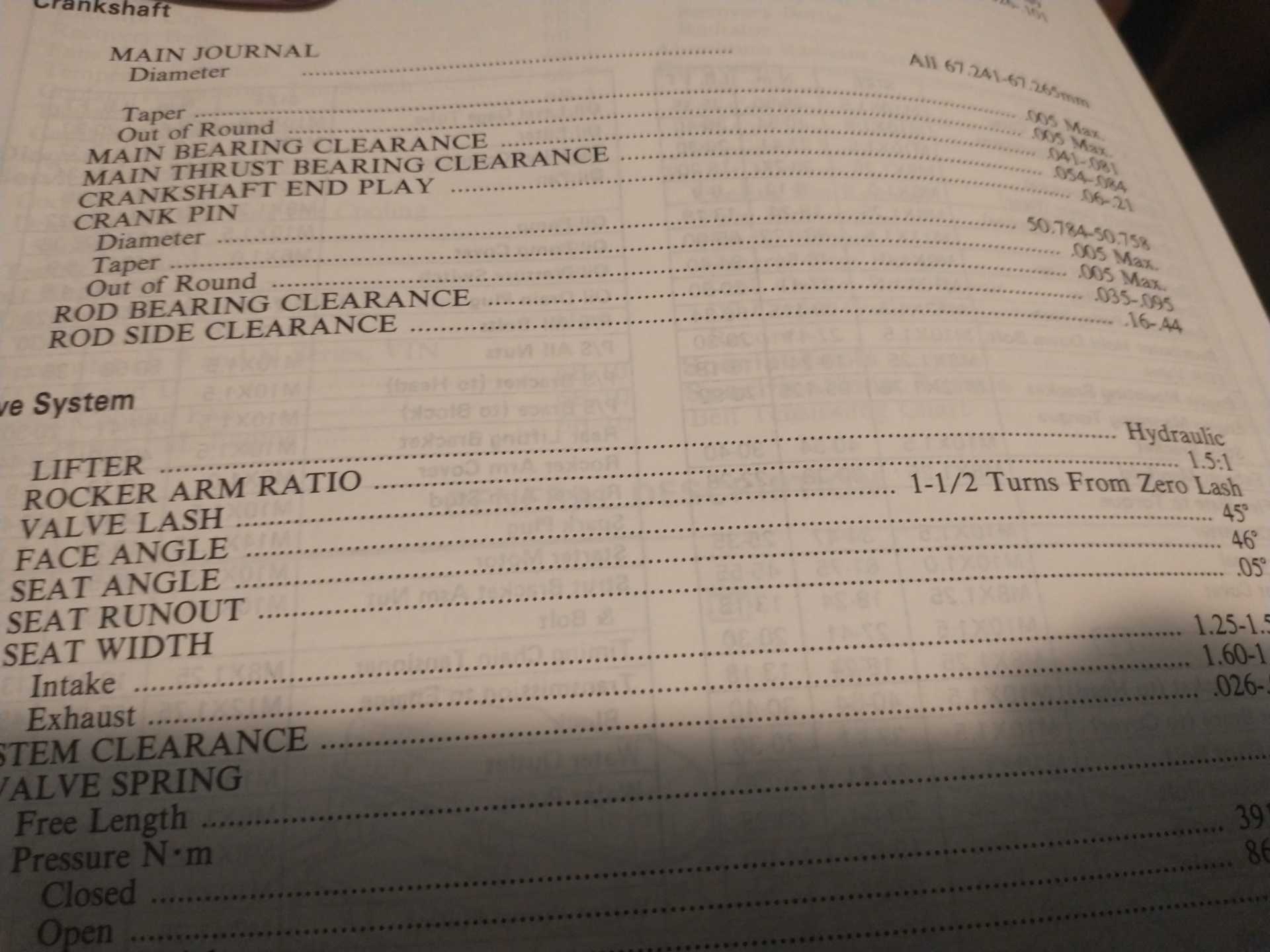

Another thing I found while looking in the manual for this is the valve lash adjustment, I don't know if my tired brain is reading this wrong, but it appears that you tighten just until you can't turn the pushrod, then tighten it another 1.5 turns

Anyhow for replacement bolts/head gaskets, look on Rock auto, compare part numbers, if they are both the same, then get whichever you want, although the head gaskets might be sized differently, as the cyl bore is 3mm larger, don't know if that would make a difference or not (also assuming the heads are the same, even if the cyl bore is not?)

|

|

|

1985 Fiero GT

|

MAY 24, 01:34 AM

|

|

|

Hmm, I'm just reading threads that warn against doing 1.5 additional turns, saying perhaps the manual intended to say one 0.5 additional turn, instead of 1.5 turns, now I'm confused haha.

|

|

|

Patrick

|

MAY 24, 02:22 AM

|

|

| quote | Originally posted by 1985 Fiero GT:

Another thing I found while looking in the manual for this is the valve lash adjustment, I don't know if my tired brain is reading this wrong, but it appears that you tighten just until you can't turn the pushrod, then tighten it another 1.5 turns.

|

|

Lucky for you, I researched this quite extensively several years ago.

| quote | Originally posted by Patrick Here:

I wanted to take this opportunity to discuss the methodology of adjusting valve lash. The last time I adjusted valve lash was back in 1977 after I swapped a lumpy camshaft with solid lifters into my big-block 396ci Chevy.

This is the first time I've ever adjusted the valve lash on a 2.8 engine. I've read all the numerous posts about which rockers to adjust when, and "spinning" the push rods while tightening the rocker nuts until the push rods start to bind. Then there's the debate about how many turns of the nut after finding zero lash. I gotta be honest... I didn't feel a lot of those posted methods were very convincing. Here's how I did it....

First, for each cylinder I determined when it was at TDC of the compression stroke. This was done by rotating the crank using a wrench on the front pulley (with the spark plugs out it's easy) and seeing when the exhaust valve is closing and the intake valve is opening. That's TDC, but on the exhaust stroke. Turn the crank 360° (watch the timing marks go by... stop on the third one), and this is TDC on the compression stroke.

With the rocker nut loose, grab the rocker at the valve end tip and lift it. You'll notice the play. You don't even have to see it, you can feel it. Slowly start to turn the socket wrench on the rocker nut and you can feel the play becoming less and less. And now I've got something critical to add...

Do not get fooled by a lack of play due to your socket wrench putting pressure on the rocker ball.

Lucky for me, I noticed this very quickly, but I can certainly see how an inexperienced mechanic could get completely fooled by this! It is very important that the socket wrench is taken right off the rocker nut when lifting the end of the rocker to check for play. (A deep socket rests on the rocker ball, and the wall of the socket can also push against the inside of the rocker, both of which can prevent the rocker from easily moving.) Otherwise it's way too easy to come to the conclusion that you've reached zero lash when in reality you could still be way off. Using this method I was able to determine zero lash to perfection.

And now the lifter pre-load. I gave each rocker nut exactly 1 1/2 turns after finding zero lash. I suspect why some people suggest less pre-load is because the "spinning" push rod method to find zero lash is so imprecise that many people would probably have already gone beyond zero lash. Therefore, adding another 1 1/2 turns would be exceeding the recommended lifter pre-load for this application (if the rocker nut was tightened too much while setting zero lash).

Before I removed the original rockers, I checked to see what the pre-load was. It was all over the place, but it seemed like 1/2 turn past zero lash was the usual. That's not enough.

|

|

|

|

|

1985 Fiero GT

|

MAY 24, 02:40 AM

|

|

| quote | Originally posted by Patrick:

Lucky for you, I researched this quite extensively several years ago.

|

|

Thanks, I'll be needing to do mine soon, so this is very helpful, I will certainly be doing it like you suggest!

|

|

|

82-T/A [At Work]

|

MAY 24, 08:17 AM

|

|

| quote | Originally posted by 1985 Fiero GT:

I don't know, I've read places that the original head bolts are reusable and not torque to yield, but replacements are, the factory service manual doesn't say to replace them, it does say to clean them, so that might indicate they are "reusable". I'm getting new fel pro bolts for mine, but it is interesting. I wonder if the torquing instructions are different for the TTY bolts vs the factory originals.

Anyhow for replacement bolts/head gaskets, look on Rock auto, compare part numbers, if they are both the same, then get whichever you want, although the head gaskets might be sized differently, as the cyl bore is 3mm larger, don't know if that would make a difference or not (also assuming the heads are the same, even if the cyl bore is not? |

|

Yeah, I honestly wasn't sure... they show two different part numbers for a variety of different bolt sets... mostly because the 3.4 Camaro / Firebird has a unique / weird bolt that I don't see in the Fiero bolt sets. The only thing I did see though, was a bolt set from FelPro (likely the one you're getting) which seemed to have the same part number between the two of them. It also came with a ground stud for the outside of the cyl head that you can use to connect your battery terminal onto (like on the Iron Dukes).

The last time I tried to do a cyl head bolt on a V6/60 was ~1998, and I ripped the threads out. I'm convinced my torque wrench was garbage and simply didn't work. Or I didn't understand the difference between Newton Meters and Foot-Pounds. Either way, I bought a whole new set of torque wrenches.

This is for my 3.4 though, and it's a reman... so I don't really know what bolts it has on it. It's best to just change them out.

For head gaskets, I just ordered a set for the 3.4 due to the obvious bore size difference. I ended up going with Mahle since they had Graphite gaskets. I wanted the Victor Reinz, but they were out. FelPro is still great... but most of their stuff is made in China now, and honestly... unless it's old stock from the 90s or early 2000s... I really don't like to use FelPro anymore. I ended up buying the last two Mahle head gaskets they (Rock Auto) had.

| quote | Originally posted by 1985 Fiero GT:

Another thing I found while looking in the manual for this is the valve lash adjustment, I don't know if my tired brain is reading this wrong, but it appears that you tighten just until you can't turn the pushrod, then tighten it another 1.5 turns |

|

Hah... yes, it was like 15 years ago since I last did this... so definitely don't take anything I say as gospel until I've gone and done this again. I get to do all this stuff over again. But I was just a kid 1,200 miles away from my parents, wrenching in a parking lot on the weekends when the rental office was closed (so they wouldn't see).

|

|

|

1985 Fiero GT

|

MAY 24, 08:35 AM

|

|

Yeah, the fel pro bolt set has all the bolts and one stud, my Fiero used the stud as well (off hand I forget what for, and I just did this on Monday) I seem to recall it not being a "necessary" thing, something I could leave off or fasten somewhere else, and the Fiero store set, doesn't have the stud pictured, but I'll probably use the stud anyhow.

Hey, the fact you remember all you do is pretty good, considering I can't remember what that stud is for, and I disassembled that on Monday haha.

|

|

|

82-T/A [At Work]

|

MAY 24, 11:16 AM

|

|

| quote | Originally posted by 1985 Fiero GT:

Yeah, the fel pro bolt set has all the bolts and one stud, my Fiero used the stud as well (off hand I forget what for, and I just did this on Monday) I seem to recall it not being a "necessary" thing, something I could leave off or fasten somewhere else, and the Fiero store set, doesn't have the stud pictured, but I'll probably use the stud anyhow.

Hey, the fact you remember all you do is pretty good, considering I can't remember what that stud is for, and I disassembled that on Monday haha. |

|

Well, just going off this rebuild I'm doing with my daughter on the Iron Duke, it seems like the head-bolt with the studs are used as grounding points. Which makes total sense of course, you're literally tying directly into the block itself. You'll notice that those bolts all seem to have a "Teflon" tape on them. I don't think it actually is Teflon, and I'm wondering if maybe it's some kind of dry-dialectic wrap. Both the bolts for my daughter's Iron Duke (which had studs on them) had that... and neither one of them went into a water port. So, who knows...

|

|

|

1985 Fiero GT

|

MAY 24, 01:56 PM

|

|

| quote | Originally posted by 82-T/A [At Work]:

Well, just going off this rebuild I'm doing with my daughter on the Iron Duke, it seems like the head-bolt with the studs are used as grounding points. Which makes total sense of course, you're literally tying directly into the block itself. You'll notice that those bolts all seem to have a "Teflon" tape on them. I don't think it actually is Teflon, and I'm wondering if maybe it's some kind of dry-dialectic wrap. Both the bolts for my daughter's Iron Duke (which had studs on them) had that... and neither one of them went into a water port. So, who knows... |

|

It's not the ground, that is above one of the exhaust ports, I'm pretty sure it is to hold the bracket that holds the hard fuel lines,

|

|

|

cartercarbaficionado

|

MAY 24, 02:11 PM

|

|

| quote | Originally posted by 1985 Fiero GT:

It's not the ground, that is above one of the exhaust ports, I'm pretty sure it is to hold the bracket that holds the hard fuel lines,

|

|

on some 2.8s it's both actually. these get super weird and weirdly enough some 3.4s and 2.8l use the same headbolts despite having different head thicknesses and my 84 iron duke and my v6 actually directly use the same headbolts..which is the exception not the norm for Fieros

|

|

|

|