|

| Upper control arm (Page 1/2) |

|

hunter29

|

JUN 14, 04:09 PM

|

|

Hopefully this thread will get attention.

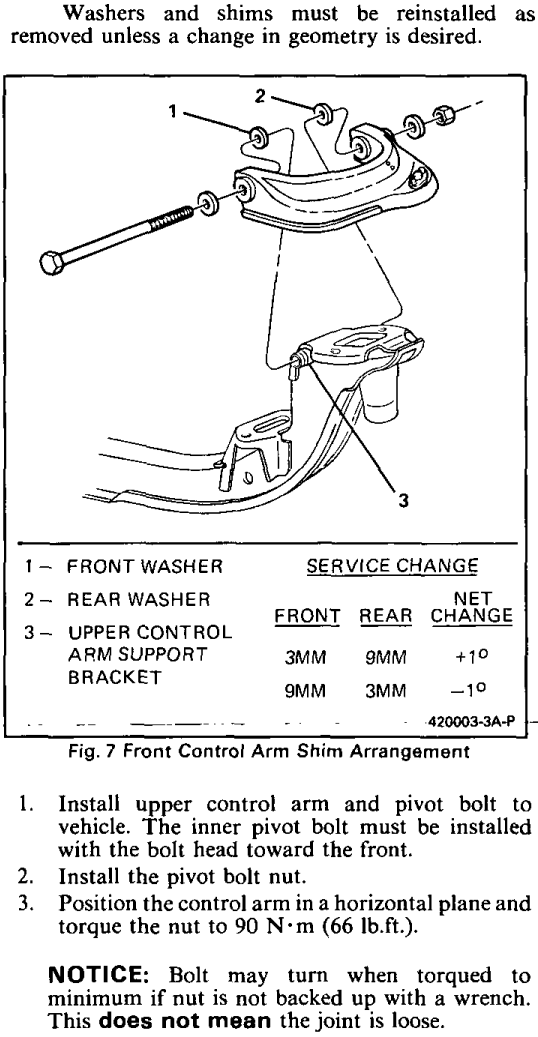

I have installed the upper control arm on my 86 exactly as it came from the factory with 6mm washers.

When I follow TFS manual and try to torque it to 66# it binds and won't move.

I'm not understanding what is going on here.

How is this supposed to work?

|

|

|

IMSA GT

|

JUN 14, 05:08 PM

|

|

He answered your question in the other thread:

| quote | Originally posted by Yellow-88:

The control arm moves by twisting the rubber bushings. Human strength will be hard to move it very far. They are bushings not bearings. The bushing doesn't actually rotate around anything like a bearing around a shaft. it just twists the rubber. |

|

|

|

|

Patrick

|

JUN 14, 05:24 PM

|

|

And also make sure the car's weight is on the wheels before the control arm bolts are tightened. In other words, the bolts aren't tightened with the suspension hanging.

|

|

|

armos

|

JUN 14, 05:31 PM

|

|

[edit - I think I misunderstood your question. You mean the arm is binding, not the nut.]

As mentioned above, if you're using rubber bushings, then you want it to be tightened with the arm in the position it will be when the car is resting with load on the suspension. That way the rubber bushings won't be under constant strain. The manual implies that putting the arm in a "horizontal plane" may be approximately correct. But actually putting load on it would be more exact.

[This message has been edited by armos (edited 06-14-2024).]

|

|

|

hunter29

|

JUN 15, 06:16 PM

|

|

|

Thanks guys I got it. Should have it back together soon. Unless those springs beat me.... lol

|

|

|

Yellow-88

|

JUN 22, 12:08 PM

|

|

|

It's nice to see someone using new rubber bushings instead of jumping on the "poly" band wagon.

|

|

|

hunter29

|

JUN 23, 07:45 PM

|

|

|

That's because I did my homework, thanks

|

|

|

82-T/A [At Work]

|

JUN 24, 12:03 PM

|

|

| quote | Originally posted by Patrick:

And also make sure the car's weight is on the wheels before the control arm bolts are tightened. In other words, the bolts aren't tightened with the suspension hanging. |

|

I screwed this up when I was restoring my car (just before I put it in storage 13 years ago). I'm going to have to re-do a lot of what I've done when I finally get it out of storage.

|

|

|

1985 Fiero GT

|

JUN 24, 01:42 PM

|

|

| quote | Originally posted by 82-T/A [At Work]:

I screwed this up when I was restoring my car (just before I put it in storage 13 years ago). I'm going to have to re-do a lot of what I've done when I finally get it out of storage. |

|

Didn't you use poly on your bushings? If so then that doesn't matter, only for rubber, poly is meant to rotate around the inner sleeve, rubber is bonded to both the inner and outer sleeve, so by doing it wrong you can tear it, but with poly it just rotates freely.

|

|

|

Yellow-88

|

JUL 01, 10:01 PM

|

|

| quote | Originally posted by 1985 Fiero GT:

Didn't you use poly on your bushings? If so then that doesn't matter, only for rubber, poly is meant to rotate around the inner sleeve, rubber is bonded to both the inner and outer sleeve, so by doing it wrong you can tear it, but with poly it just rotates freely. |

|

I think the intent of the designers of poly bushings was uncertain. Did they think that they would twist some and rotate a little bit? They squeak wicked bad if you let them get dry. That means that they do bind up some what. If they were supposed to rotate, than the inside shaft tube thing is too small diameter for the loads they must endure, especially during robust driving, so It tends to eat into the poly material. New rubber bushings may actually hold their shape as long or longer than poly. I've never seen a side by side test.

|

|

|