|

| v8 archie starter issues (Page 1/1) |

|

cartercarbaficionado

|

AUG 12, 07:20 AM

|

|

dealing with a strange one here. (powermaster 9000) starter is just grinding and I think it needs to be lower but I can't actually get the pinion any lower and need it kept close against the block so the tooth engagement is correct. it's at full width and decent contact about halfway down the ring gear tooth surface but will not engage fully on its own. I was thinking the bendix was faulty but it moves alright I guess? could be the solenoid but not sure. I do have the original one and I might try swapping parts between em and try to make something that works more than once.

I did ask archie and it should be working fine? it is totally possible it's an installation error which upon applying starter power causes issues but not when prying the pinion out with a screwdriver.

I'm probably just gonna have to do some re engineering of the starter and possibly the mount. (widening holes to get a bit more adjustment and maybe making cam bolts to keep adjustment simple but we shall see.)

|

|

|

fieroguru

|

AUG 12, 09:27 PM

|

|

This thread is bringing back memories...

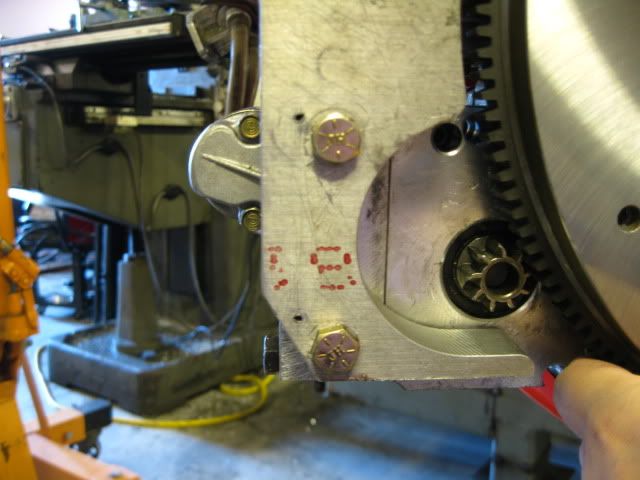

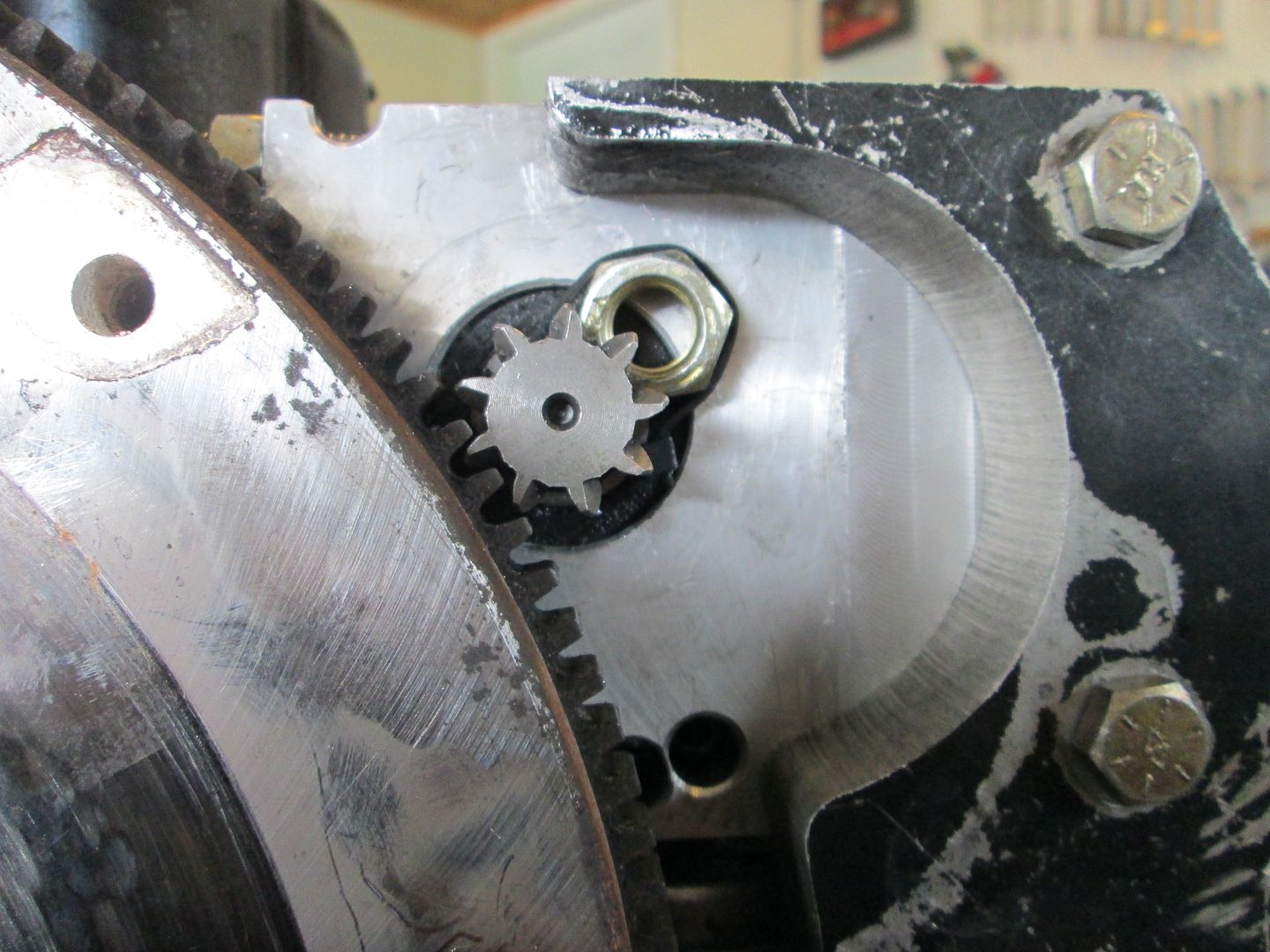

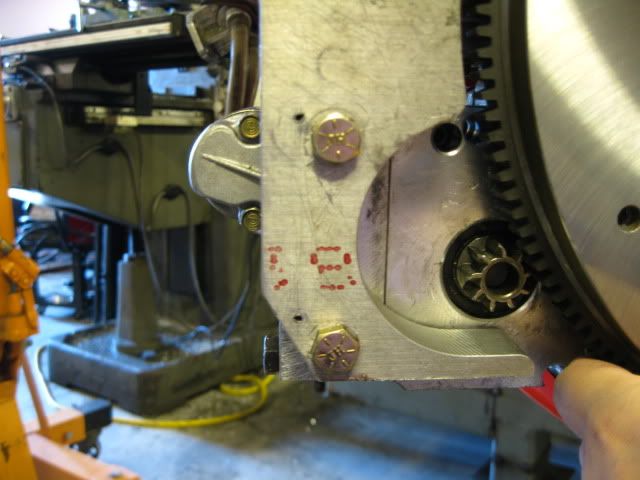

With the 4 bolts holding everything together, and the clearances in each hole, the starter can be all over the place.

It is best when the transmission is off, to get everything lined up and then pin the starter to the mounting block and the mounting block to the adapter plate so it can't move out of position. It also allows later removal and installation while keeping the proper alignment.

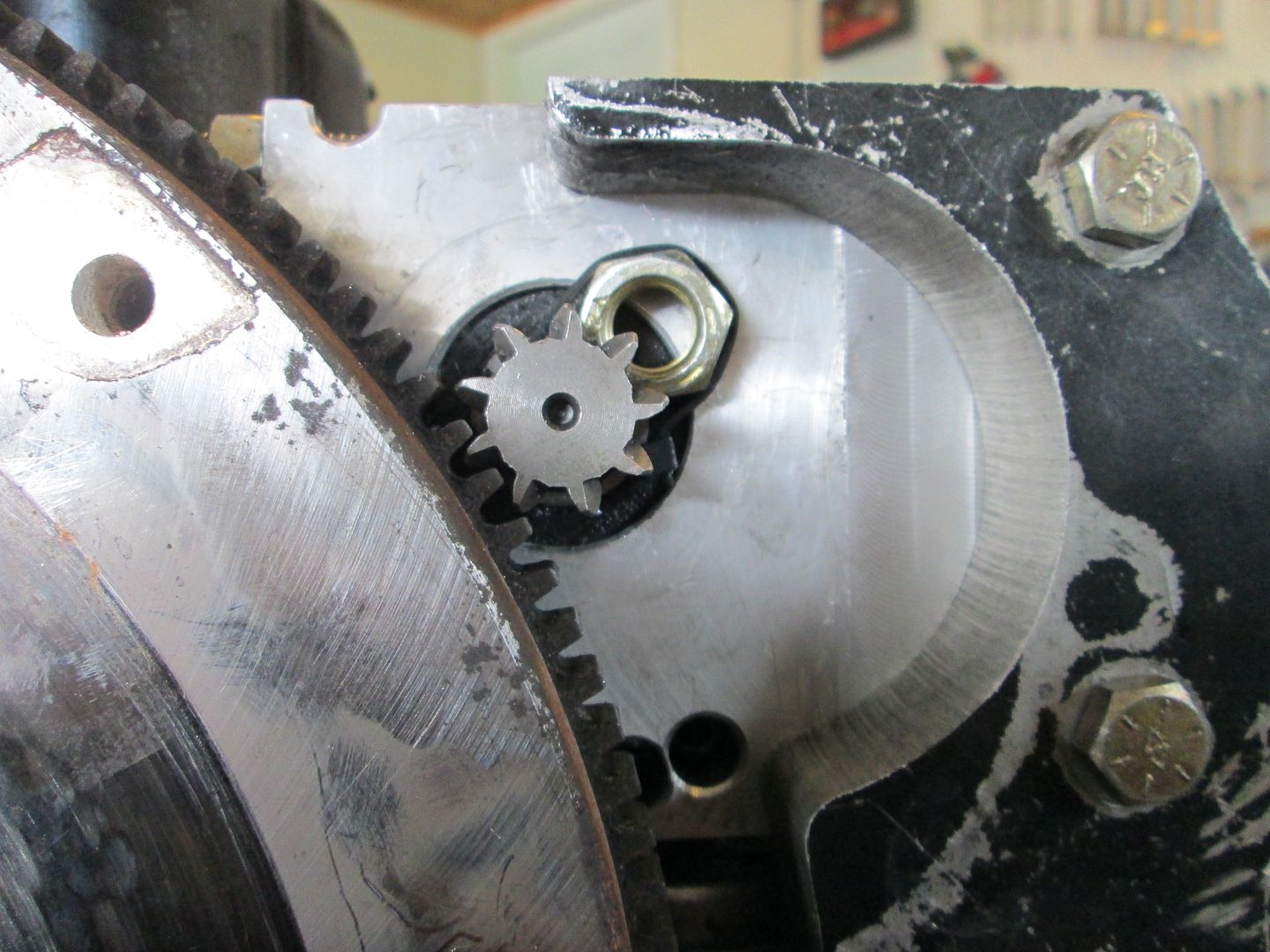

I used some 3/8" nuts under the pinion gear to keep it extended for mockup.

Pin the starter to the block first making sure they are both flat to the adapter plate.

Then drill two 1/8" dowel pin holes that lock the mounting block to the adapter plate.

Here is the pin and depth of the pin in the block

On the other one, it used a 142 tooth ring gear, so I had to remake the mounting block, so on that one I counter bored the bolt holes and used hollow dowels at the bolt locations:

|

|

|

buddycraigg

|

AUG 14, 12:20 AM

|

|

| quote | Originally posted by fieroguru:

This thread is bringing back memories...

|

|

You're doing better than me old man.

I can't remember **** about that except for the 4 bolts that you can adjust all over the place.

|

|

|

cartercarbaficionado

|

AUG 14, 03:41 PM

|

|

| quote | Originally posted by fieroguru:

This thread is bringing back memories...

With the 4 bolts holding everything together, and the clearances in each hole, the starter can be all over the place.

It is best when the transmission is off, to get everything lined up and then pin the starter to the mounting block and the mounting block to the adapter plate so it can't move out of position. It also allows later removal and installation while keeping the proper alignment.

I used some 3/8" nuts under the pinion gear to keep it extended for mockup.

Pin the starter to the block first making sure they are both flat to the adapter plate.

Then drill two 1/8" dowel pin holes that lock the mounting block to the adapter plate.

Here is the pin and depth of the pin in the block

On the other one, it used a 142 tooth ring gear, so I had to remake the mounting block, so on that one I counter bored the bolt holes and used hollow dowels at the bolt locations:

|

|

I wish I could but the engine is installed in the car and was working. I'm debating on whether or not the 9000 starter could have a different Pinon tooth count. honestly suprised archie didn't flip the mounting area 90 degrees to make it shimable like a stock gm starter.

I do have a slight concern and that is the starter isn't quite straight when fully tight so maybe it's at a slight angle for some reason?

|

|

|

fieroguru

|

AUG 14, 08:41 PM

|

|

Before I got smart and started pinning them before everything was installed in the car, I had to replace mine with it in the car.

Tighten the two bolts from the starter to the block making sure the mounting face to the adapter plate is flat and true.

Use the nut trick to get the pinion extended.

Install the starter but keep the two bolts between the starter block and adapter plate slightly loose.

Bend a long nail into a "L" and insert the short leg between the pinion gear and the ring gear.

Push the starter into position with the nail setting the gear mesh.

Tighten the two adapter to starter block bolts.

Remove the nail and the nut.

This is one of those tasks that helps to have a 3rd hand, but not required with some creativity.

|

|

|

cartercarbaficionado

|

AUG 15, 12:49 AM

|

|

| quote | Originally posted by fieroguru:

Before I got smart and started pinning them before everything was installed in the car, I had to replace mine with it in the car.

Tighten the two bolts from the starter to the block making sure the mounting face to the adapter plate is flat and true.

Use the nut trick to get the pinion extended.

Install the starter but keep the two bolts between the starter block and adapter plate slightly loose.

Bend a long nail into a "L" and insert the short leg between the pinion gear and the ring gear.

Push the starter into position with the nail setting the gear mesh.

Tighten the two adapter to starter block bolts.

Remove the nail and the nut.

This is one of those tasks that helps to have a 3rd hand, but not required with some creativity. |

|

my earlier response never sent. lovely.

I've done that but the starter still grinds. so a new one was order since we think it's bad which is unfortunate but not a huge suprise. I'm gonna clean and stone every surface flat with a peice of glass and sand paper to make sure its good

|

|

|

fieroguru

|

AUG 15, 06:50 AM

|

|

| quote | Originally posted by cartercarbaficionado:

my earlier response never sent. lovely.

I've done that but the starter still grinds. so a new one was order since we think it's bad which is unfortunate but not a huge suprise. I'm gonna clean and stone every surface flat with a peice of glass and sand paper to make sure its good |

|

If it has been grinding a bunch, you should check the ring gear teeth for wear. It there are bad spots in the ring gear, then it will need to be replaced as well.

|

|

|

cartercarbaficionado

|

AUG 16, 05:13 AM

|

|

| quote | Originally posted by fieroguru:

If it has been grinding a bunch, you should check the ring gear teeth for wear. It there are bad spots in the ring gear, then it will need to be replaced as well. |

|

it's good enough to be used still fortunately. barely any wear at all

|

|

|