|

| Fuel Pump Testing for 3800SC swap (Page 1/2) |

|

GodSend

|

AUG 21, 08:46 PM

|

|

Hi Guys,

First of all, apologies to anyone who frequents the 3800 facebook swap group who has been trying to help me there. I appreciate all the feedback, but its hard to keep a conversation going on facebook when things drop off the top of the page and few people were starting to get a little annoyed with me. Anyways :

Background : 3800sc swap into 88 with getrag 5sp. Brand new build has not been on the road. Harness was pulled from a Fiero with a 3800 NA in a junkyard. The assumption is everything was working as it was in a crash. Year of fiero unknown, but I know it was not an 88 as thats what I have and 100% i would have grabbed the calipers etc like I always do. Fiero was a manual.

Im having problems with starting and my fuel pump. I can hear the relay click, but the pump does not prime. Here is what I tested s far :

Relay is a 5 pin Hella 3611

- relay (has constant power to pin 87) - thick orange wire

- pin 85 is ground

- pin 86 energizes with key turned on (relay clicks when plugged in) - thinner orange wire (from ECU)

- pin 30 has continuity to Tan wire on fuel pump harness

- pin 30 gets 12+ volts when key is turned on. (the result of 86 energizing the coil) as witnessed on Tan wire of fuel pump harness (NOTE THE POTENTIAL ISSUE BELOW)

On the engine side of the fuel pump harness

- Black pin is ground

- Middle (goes to fuel gauge)

- Tan has nothing with key off, and gets the 12+ when turned on. HOWEVER ONLY FOR A 1/2 SECOND. I was under the impression the pump should prime for about 3(ish) seconds correct? Maybe a bad relay?

I also did some testing from the yellow fuel pump harness down. I actually ended up swapping out my fuel pump based on my testing and facebook feedback, but its still doing the same thing and I want to confirm this is how it SHOULD work

If I give ground to the black wire, and +12 to the tan wire I get strong fuel flow, upto 40+ psi in a second or two based on my fuel rail gauge. Bench tested as well when swapping the pump. When I was first testing (pre and post FP swap) I was noticing my +12 wire was getting very hot after a few seconds, but I believe this is due to its small gauge (like a 20 gauge wire). Once I upped it to a 12/14 gauge, i did not detect the same heat issue, although I did only run it for about 5 seconds.

Based on the heating jumper wire, I decided to some probing of the Yellow harness (unplugged), and this is what led me to drop the tank and replace the pump.

-Black wire pin shows continuity to ground

-Tan wire pin shows continuity to ground

- Black and Tan wire (outer pins) show continuity to each other

A few people suggested that means the pump is bad, but others said thats to be expected? I went with the "pump bad" crowd assuming that was the source of my wire heat (before I upped the wire gauge) as I was applying +12 to a pin showing continuity to ground. After replacing the pump and making sure the wiring was okay inside the tank and along the outside I still have the same readings.

So, based on everyones thoughts, should I be seeing grounds on both pins and continuity when sitting there unplugged? If I jumper it all seems fine, so im leaning more towards me just overthinking that part, and maybe I just have a weak/failing relay?

|

|

|

Patrick

|

AUG 21, 09:25 PM

|

|

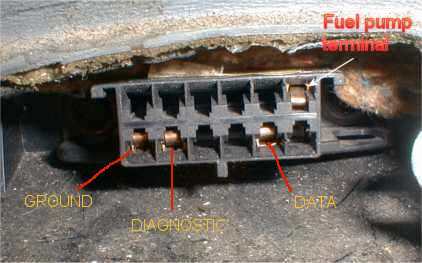

I don't know if it's any different with a 3800 swap... but with a stock Fiero, you can bypass the fuel pump relay and test the fuel pump directly by applying 12v (from the cigarette lighter) to fuel pump terminal of the ALDL port.

|

|

|

Dennis LaGrua

|

AUG 21, 10:51 PM

|

|

Put a pressure gauge on the fuel rail then turn the ignition to the ON position. You should see pressure on the fuel line. If not the the pump is not being energized. There is a ground and power wire to the pump and thats it. The other wire is for the gas gauge. Check to see if the pump is getting voltage when the ignition is first turned on. You can check at the connector.

The Fiero ALDL connector is not used on the 3800 engine. That PCM will have an OBD2 connector. You cannot energize the fuel pump from there. ------------------

" THE BLACK PARALYZER" -87GT 3800SC Series III engine, custom ZZP /Frozen Boost Intercooler setup, 3.4" Pulley, Northstar TB, LS1 MAF, 3" Spintech/Hedman Exhaust, P-log Manifold, Autolite 104's, MSD wires, Custom CAI, 4T65eHD w. custom axles, Champion Radiator, S10 Brake Booster, HP Tuners VCM Suite.

"THE COLUSSUS"

87GT - ALL OUT 3.4L Turbocharged engine, Garrett Hybrid Turbo, MSD ign., modified TH125H

" ON THE LOOSE WITHOUT THE JUICE "

|

|

|

Patrick

|

AUG 22, 12:23 AM

|

|

| quote | Originally posted by Dennis LaGrua:

The Fiero ALDL connector is not used on the 3800 engine. That PCM will have an OBD2 connector. You cannot energize the fuel pump from there.

|

|

Dennis, thanks for mentioning that. I wasn't sure, but now I know!

|

|

|

Frenchrafe

|

AUG 22, 03:16 AM

|

|

Depending on who or how the engine swap harness was wired up, you may have a "double relay" fault.

It's a bit difficult to explain but the gist of it is either it won't start or it won't stop (in my case).

I think the problem is the earth of one relay coil is dependant of the switching side of the other relay coil.

Whatever, the system won't work well.

I fixed mine by redoing all the wiring to the fuel pump:

Signal/switch wire from ECU identified.

1 power relay with separate fused power directly from the battery.

Good direct power wire from relay to fuel pump.

Good earth for pump.

ECU signal/switch directly to the coil of the relay.

You won't need the Fiero's original fuel pump harness wiring. The 10amp fuse is now redundent.------------------

"Turbo Slug" - '87 Fiero GT. 3800 turbo. - The fastest Fiero in France! @turboslugfiero

https://youtu.be/hUzOAeyWLfM

|

|

|

GodSend

|

AUG 22, 10:20 AM

|

|

| quote | Originally posted by Dennis LaGrua:

Put a pressure gauge on the fuel rail then turn the ignition to the ON position. You should see pressure on the fuel line. If not the the pump is not being energized. There is a ground and power wire to the pump and thats it. The other wire is for the gas gauge. Check to see if the pump is getting voltage when the ignition is first turned on. You can check at the connector.

The Fiero ALDL connector is not used on the 3800 engine. That PCM will have an OBD2 connector. You cannot energize the fuel pump from there.

|

|

Ive done all that analysis. Relay clicks, but only supplies +12 volts for a fraction of a second and then shuts off (with fuel pump disconnected). I can apply ground and +12 to pump wires and it runs fine.

Im thinking my relay is bad, Unless there is some ECU setting I need to adjust in HPTuners to energize the pump for longer?

|

|

|

GodSend

|

AUG 22, 10:24 AM

|

|

| quote | Originally posted by Frenchrafe:

Depending on who or how the engine swap harness was wired up, you may have a "double relay" fault.

It's a bit difficult to explain but the gist of it is either it won't start or it won't stop (in my case).

I think the problem is the earth of one relay coil is dependant of the switching side of the other relay coil.

Whatever, the system won't work well.

I fixed mine by redoing all the wiring to the fuel pump:

Signal/switch wire from ECU identified.

1 power relay with separate fused power directly from the battery.

Good direct power wire from relay to fuel pump.

Good earth for pump.

ECU signal/switch directly to the coil of the relay.

You won't need the Fiero's original fuel pump harness wiring. The 10amp fuse is now redundent.

|

|

ill check this out. That certainly sounds like how mine is wired up. Im going to grab an exact replacement from the boneyard first and swap that in. if not ill wire something else up temporarily and see if that works. thanks.

|

|

|

GodSend

|

AUG 24, 03:10 PM

|

|

Ok guys, did a little more probing and have some more information. Would really like to try to solve this without just wiring relay in. (swapped relay with 3 other ones, all same symptoms)

.

With the key cranked (fuel pump disconnected to isolate the issue) I only get 12+ to the fuel pump harness for a fraction of a second, Im still getting the 12+ signal from the ECM to relay, however for some reason the GROUND to the relay cuts out (therefore deenergizing the relay). I cant for the life of me figure out why. The ground does not appear to be controlled by anything. I disconnected the PCM, the relay still had continuity to ground, disconnected the C203, the pcm still had ground. Finally when I disconnected c500 was the relay no longer grounded.

I checked for continuity and I have between relay around and A2 on c500 (which matches the wiring diagrams). f10 body side appears to be ground based on continuity. Is there something that potentially drop the ground from pin F10?

My first thought it so splice a ground into the relay straight from the chassis, but im worried there is some other issue going on,like the ground is dropping from everything engine side of the c500?[This message has been edited by GodSend (edited 08-24-2024).]

|

|

|

olejoedad

|

AUG 24, 06:30 PM

|

|

You're running a 3800SC with a 3800NA harness?

What is the service number on your PCM?

|

|

|

jelly2m8

|

AUG 25, 03:46 AM

|

|

| quote | Originally posted by olejoedad:

You're running a 3800SC with a 3800NA harness?

What is the service number on your PCM? |

|

That is no issue, I run my 04 3800SC on a 12year old previous build 99 3800 NA harness( The ONLY thing I had to do was lengthen the one side of the harness but no changes) . Harness means nothing past the boost solenoid, But the PCM tuning does. ( Nothing but respect to you oldjoe

All the Wizardry tuning would be for an auto. Seeing this is a manual swap reading the OP's post I am going to assume its a 'Dan' harness... Oh boy, someone got fuked.

AND BTW! FACEBOOK IS THE TRAILER PARK OF THE INTERNET.

To the OP, a proper built harness 88, auto, manual.. It should run fine, just that particular tuning will set codes. if your FPR clicks and you don't her the Fuel pump run nor get sufficient pressure, you either have a dead pump of a shoddy harness.

|

|

|

|