|

| installing Rear anti-sway bar bushings (88 GT) (Page 1/1) |

|

Profasr

|

SEP 02, 12:05 PM

|

|

I've been hearing a loud thunking over bumps and pulled the rear tires to inspect. The sway bar end links are mostly disintegrated and the bolt is just slapping in the mounting holes. I found replacements at the Fiero store and it looks easy enough to replace, but I was wondering if anyone has done this and could walk me through it so that I don't screw it up. Better yet, if someone has a video - even better!

I know a lot of you guys on here a real wrenchers, but I'm a noob and want to do it right, so any help is greatly appreciated.

Just for reference, it's a 1988 GT with T-tops and a manual and it has about 5,000 miles on it. It was a rare find this past March out in Chicago...[This message has been edited by Profasr (edited 09-02-2024).]

|

|

|

Patrick

|

SEP 02, 05:12 PM

|

|

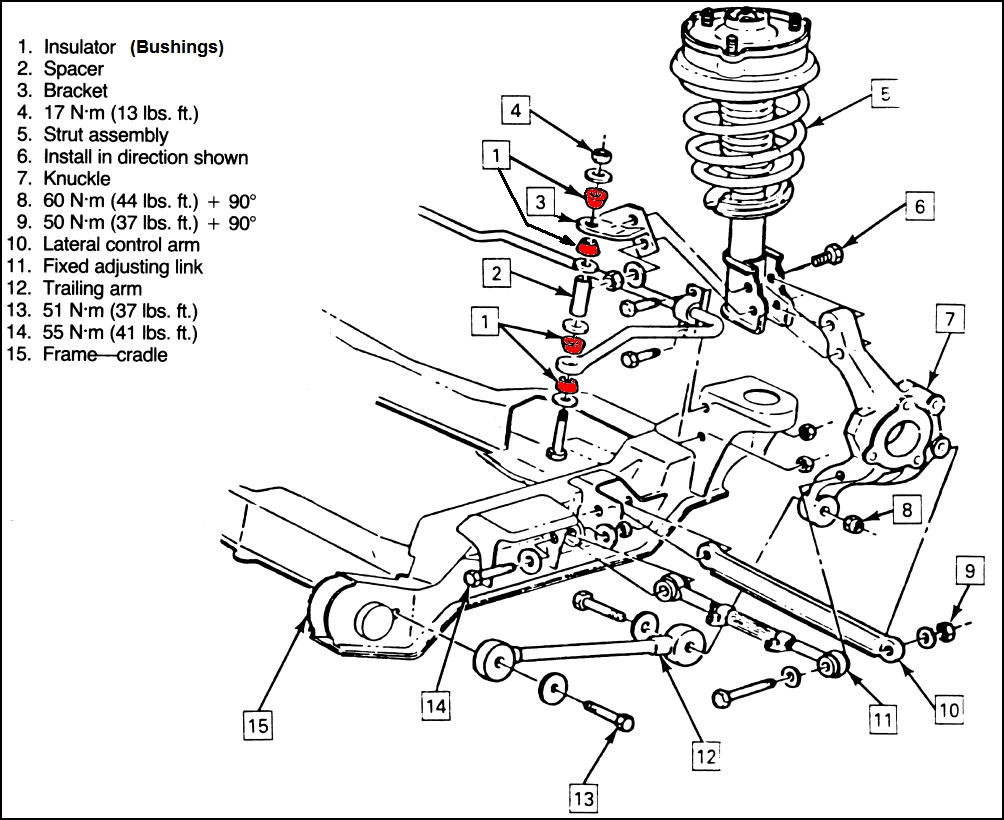

Other people can add their tips as required, but here's my contribution. Don't have one side of the car raised more than the other. Doing so would result in it being much more difficult to reassemble the end links, as you'd be fighting against the torque of the sway bar. When tightening the bolts holding the end link bushings in place, you want the bushings to be squished, but not to the point of being deformed. It's possible the bolts supplied with the Fiero Store end links are only threaded a certain amount, so it's possible you can just tighten the bolts until you run out of thread. Maybe someone who's used those end links can comment.

I've added a couple of tweaks to a diagram found online. Make sure each bushing is sandwiched between the end of the sway bar or the bracket on one side of it, and a washer on the other side of it.

|

|

|

Vintage-Nut

|

SEP 02, 06:26 PM

|

|

My Experience

Support the rear end so both axles drop to the lowest point {suspension unloaded} and remove both wheels

Soak the nuts in penetrating oil / remove both

Remove both end links/bushings {I needed to unloose the sway bar bushing bolts from the frame but still threaded in the frame nuts}

Install one side and only thread nut on the bolt a few threads

Install the other side the same

Re-tighten the sway bar bushing bolts on the frame with a torque wrench

Then tighten the link nuts with a torque wrench

|

|

|

Spadesluck

|

SEP 02, 06:31 PM

|

|

|

The hardest part is the sway bar will be under tension on both sides. When you jack the car up on one side and remove the tire you can take the sway bar end links off just fine, but the bar may pull away. The best way to get it all back together is have another jack to raise the spindle up so you can bolt it all back together. Rinse and repeat for the other side. It will make more sense once you start wrenching on it. It is all pretty straight forward. Just make sure you put all the bushings and washers on the correct way. Patrick supplied the pic.

|

|

|

Spadesluck

|

SEP 02, 06:32 PM

|

|

| quote | Originally posted by Vintage-Nut:

My Experience

Support the rear end so both axles drop to the lowest point {suspension unloaded} and remove both wheels

Soak the nuts in penetrating oil / remove both

Remove both end links/bushings {I needed to unloose the sway bar bushing bolts from the frame but still threaded in the frame nuts}

Install one side and only thread nut on the bolt a few threads

Install the other side the same

Re-tighten the sway bar bushing bolts on the frame with a torque wrench

Then tighten the link nuts with a torque wrench |

|

This works as well. Posted at the same time. ha

|

|

|

Profasr

|

SEP 03, 12:05 PM

|

|

|

Thanks for all of the replies and helpful tips!!! Great community of great people. I'll repost when the parts arrive and I have successfully reassembled the new end links.

|

|

|